- INSTALLER 7 & 11kW HRC

70

HIGH TEMPERATURE HEAT PUMP

MANUAL -

55

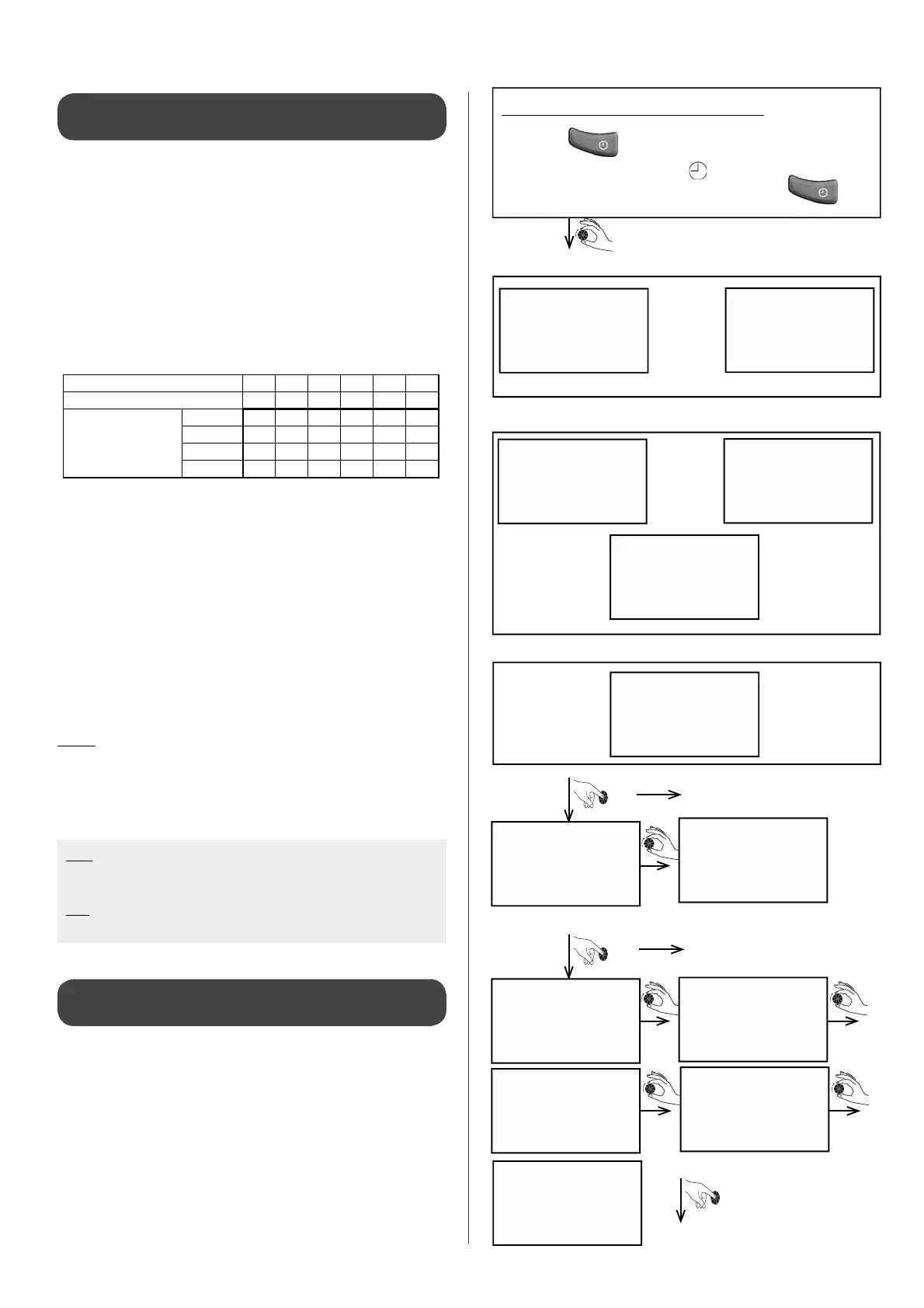

2.5 5 7.5 10 12.5 15

0.25 0.5 0.75 1 1.25 1.5

25% glycol 15.9 14.5 13.0 11.6 10.1 8.7

30% glycol 15.6 14.2 12.7 11.3 9.9 8.5

35% glycol 14.7 13.4 12.1 10.7 9.4 8.0

40% glycol 14.0 12.7 11.4 10.2 8.9 7.6

Height of installation (m)

Pre-charged pressure (bars)

(1)

Volume of water in

installation covered by 1 litre

of the expansion vessel

(litres)

(2)

- For an installation with radiators

The expansion vessel on the boiler may be su cient.

Check that the capacity of the existing expansion vessel

corresponds to the total volume of the installation (when

calculating the total volume of the installation you should take

into account 60L for the HRC

70

Pilot water tank and the volume of

the surge tank, if applicable).

- Sizing the expansion vessel

The volume of the expansion vessel which is required for the

HRC

70

Heat Pump depends on the height of the installation. You

will need to adjust the pre-charged pressure of the expansion

vessel and check that the capacity is equal to the total volume of

the installation:

A4 - Sizing the expansion vessel

(1)

: De ate and check pressure in expansion vessel if necessary

(2)

: As a guideline, take into account:

•11 litres per kW heating capacity for steel radiators

+ 50 litres bu er tank volume

• 13 litres per kW heating capacity for cast iron radiators

+ 50 litres bu er tank volume

• 17 litres per kW heating capacity for under oor heating

+ bu er tank overcapacity (if applicable)

Or, if known, use exact volume.

Example • Installation with12kW cast iron radiators

• Height of installation = 10m

• Frost / ice protection with 25% glycol

Total volume of installation = 12 x 13 + 50 = 206 litres

1 litre of expansion vessel covers11.6 litres of installation volume, so here you would need

an expansion vessel with a minium volume of 18 litres (206 / 11.6).

N.B.1 : The values given here are for a radiator installation

(water at 80°C). For an under oor heating installation,

multiply these values by 2.

N.B 2 : The concentration of monopropylene

glycol should not

be less than 25%.

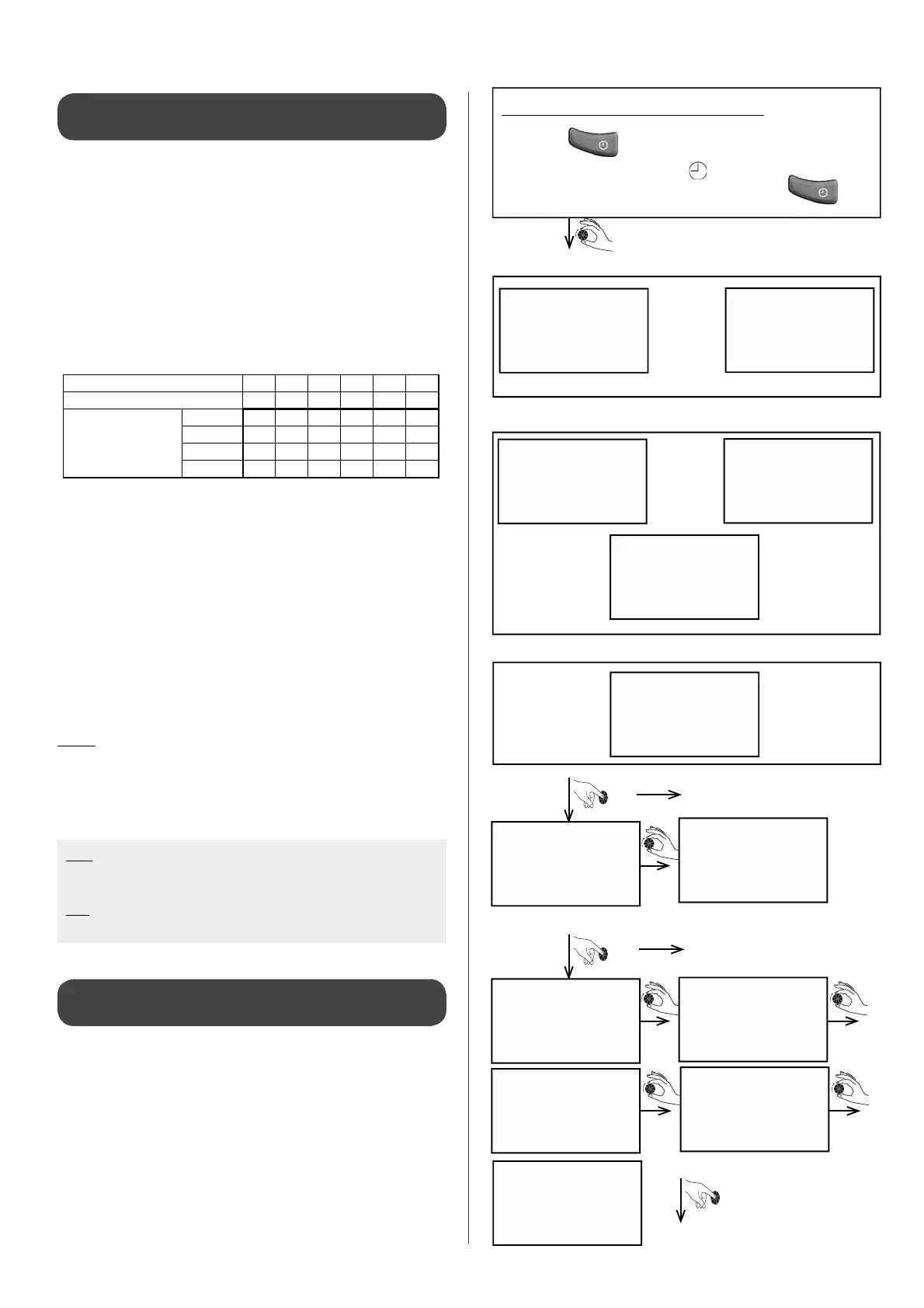

A5 - Programming heating modes

Time periods with di erent heating modes can be programmed

for each day and each circuit. The installation will automatically

follow programmed heating modes. This is not recommended

and should be avoided with a Heat Pump as it is preferable not to

lower the temperature.

Accessing the heating mode setting

• Press the

key and hold down for 3 sec.

- The screen will display

- When the symbol disappears, release the key.

where there are several circuits: if not, access directly

on day to be programmed

monday

tuesday

MODIF PRG.

new PRG.

copy PRog.

copy sun.

see PRoG.

Enter the circuit you wish to

programme and access the day

of the week to programme

Select day to be programmed

Con rm day to be

programmed

Con rm required

operation

Display depends on con guration programmed

RADIAToR

1

heat. floor

1

or

Circuit 1

RADIAToR

2

heat. floor

2

sanitary

2

or

or

Circuit 2

CIRC.

1-2

Both circuits at the same time

Loading...

Loading...