Check from time to time that the condensates are draining

properly:

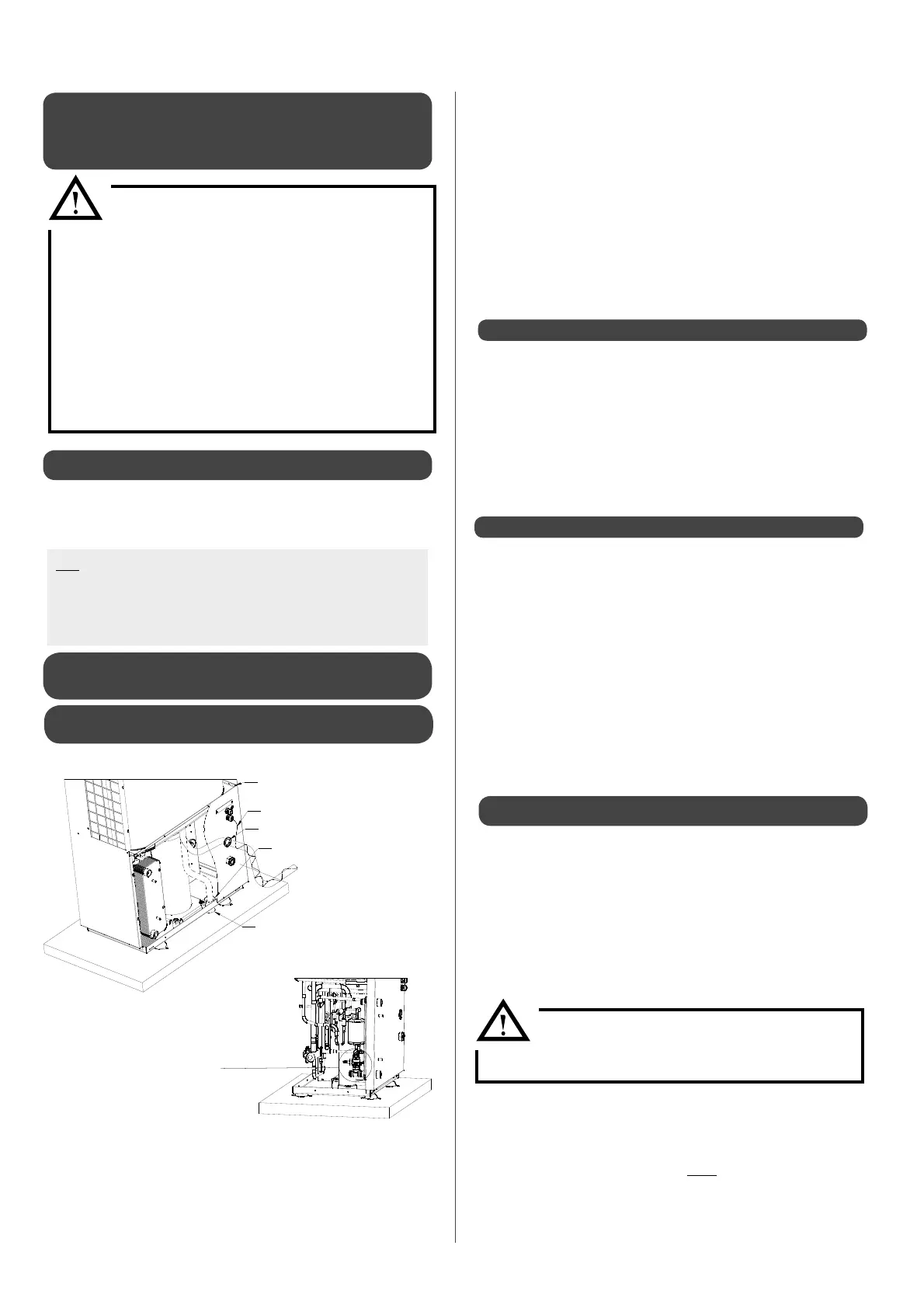

- Remove the back panel

- Check the drainage hole for blockages

- Clean the condensates collection trough as deposits from air

intake may accumulate here.

- Clean the exible drainage hose

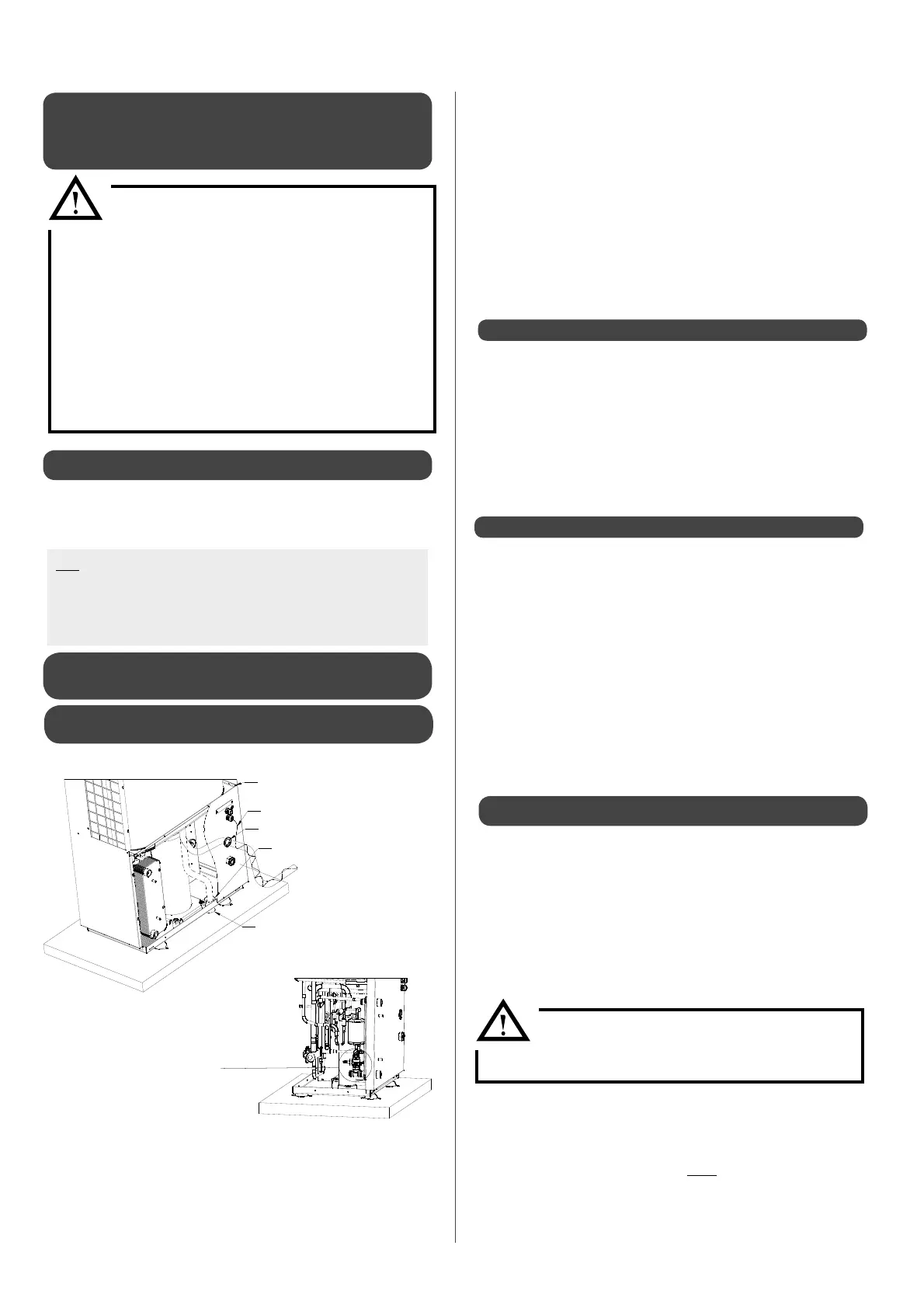

Case a : drainage from underneath

Cas b : drainage from the back

Check that the pressure relief valve is properly sealed. It should

not leak if the water pressure is under 2.5 bar.

6.2.1 - Water circuit condensate drainage

6 - MAINTENANCE AND

REPAIRS

•In order to ensure the best performances

from your HRC

70

Heat Pump it should be

maintained.

• An annual maintenance check is recommended

on the hydraulic heating circuit, to be

carried out by a quali ed professional.

•Any work undertaken on the refrigerant

circuit MUST be carried out by a quali ed

professional with a category 1 certi cate

of aptitude

•Switch the appliance off before opening it

6.1 - General information

6.2 - Hydraulic circuit maintenance

After the appliance has been running for a few days, it is advisable

to check that the water circuit is watertight and that condensates

are draining correctly.

N.B: In case of maintenance work or decommissioning

an appliance, please respect all environmental

protection instructions concerning recovery,

recycling and disposal of consumables and

components.

Pressure relief valve

Plastic cap (case a)

Heater cable

Membrane grommet

(case b)

Opening in concrete slab

(case a)

Condensates collection tray

6.2.2 - HRC

70

Pilot

We would advise you to have an annual maintenance check

carried out on the HRC

70

Pilot, which should be done by a

quali ed professional.

• When operating with electrical back-up, after the appliance has

been running for a few days and then at least once a year, all the

electrical power connections (switches and heating elements)

should be checked to ensure that they are properly tightened.

• Clean the valve lter

The HRC

70

Heat Pump contains type R290 refrigerant. This means

that it is not subject to the regulations on the greenhouse e ect

an does not require an annual maintenance check by a quali ed

professional.

However, we would recommend that from time to time (at least

once a year) the evaporator ns are cleaned if they have collected

leaves or dust on them. This should be done by using a vacuum

cleaner or spraying them with water.

Never clean the nned heat exchanger

with high-pressure cleaning

equipment: this could damage the ns.

In case of repair work on the HRC

70

Heat Pump, the refrigerant

circuit or the electrical box, it is important to follow the

instructions below:

Any work on the refrigerant circuit must be undertaken by a

quali ed professional with a category 1 certi cate of aptitude. It is

forbidden to release gas from the refrigerant into the atmosphere

and it is obligatory to recover the refrigerant before doing any

work on the circuit.

6.3 - Heat Pump maintenance

6.2.3 - Heating circuit maintenance

• Release any trapped air in the HRC

70

Pilot.

• Check that the whole circuit is watertight, as well as the pressure

relief valves.

• Check the hydraulic pressure. This should not be any higher than

the water pressure in the expansion vessel. It should never be

higher than 2.5 bar when hot. If the water pressure is low, check

that all of the circuitry is watertight before adding more water.

• Check the composition and condition of the water in the heating

circuit.

• Check the hydrualic circuit, cleaning the lter and checking the

water quality (pH level, anti-freeze, etc.).

Loading...

Loading...