DL205 User Manual, 4th Edition, Rev. B

2–29

Chapter 2: Installation, Wiring and Specifications

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A

B

C

D

I/O Wiring Checklist

Use the following guidelines when wiring the I/O modules in your system.

1. There is a limit to the size of wire the modules can accept. The table below lists the suggested

AWG for each module type. When making terminal connections, follow the suggested torque

values.

*NOTE: 16 AWG Type TFFN or Type MTW is recommended. Other types of 16 AWG may be acceptable,

but it really depends on the thickness and stiffness of the wire insulation. If the insulation is too thick or

stiff and a majority of the module’s I/O points are used, then the plastic terminal cover may not close

properly or the connector may pull away from the module. This applies especially for high temperature

thermoplastics such as THHN.

2. Always use a continuous length of wire, do not combine wires to attain a needed length.

3. Use the shortest possible wire length.

4. Use wire trays for routing where possible.

5. Avoid running wires near high energy wiring. Also, avoid running input wiring close to output

wiring where possible.

6. To minimize voltage drops when wires must run a long distance , consider using multiple wires for

the return line.

7. Avoid running DC wiring in close proximity to AC wiring where possible.

8. Avoid creating sharp bends in the wires.

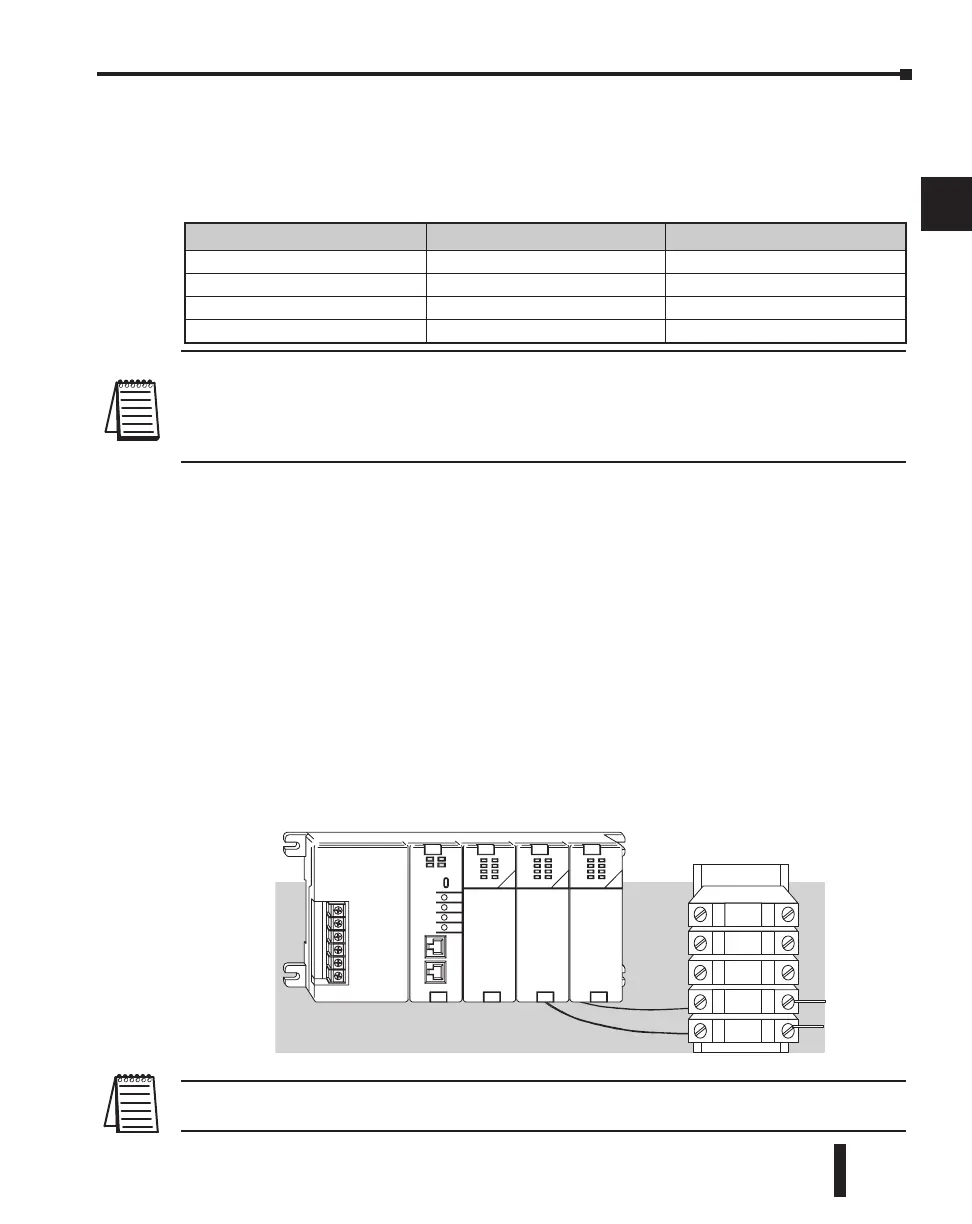

9. To reduce the risk of having a module with a blown fuse, we suggest you add external fuses to your

I/O wiring. A fast blow fuse, with a lower current rating than the I/O module fuse can be added to

each common, or a fuse with a rating of slightly less than the maximum current per output point

can be added to each output. Refer to our catalog for a complete line of DINnectors, DIN rail

mounted fuse blocks.

NOTE: For modules which have soldered or non-replaceable fuses, we recommend you return your module

to us and let us replace your blown fuse(s) since disassembling the module will void your warranty.

Module type Suggested AWG Range Suggested Torque

4 point 16* – 24 AWG 7.81 lb-inch (0.882 N•m)

8 point 16* – 24 AWG 7.81 lb-inch (0.882 N•m)

12 point 16* – 24 AWG 2.65 lb-in (0.3 N•m)

16 point 16* – 24 AWG 2.65 lb-in (0.3 N•m)

Safety Guidelines

DINnector External Fuses

(DIN rail mounted Fuses)

Loading...

Loading...