Do you have a question about the Beckman Coulter UniCel DxC Synchron 800 and is the answer not in the manual?

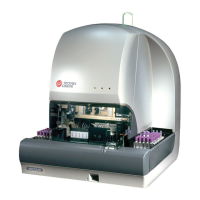

| Type | Clinical Chemistry Analyzer |

|---|---|

| Throughput | Up to 800 tests per hour |

| Sample Capacity | Up to 120 samples |

| System Type | Random Access |

| Sample Type | Serum, Plasma, Urine |

| Power Requirements | 200-240 VAC, 50/60 Hz |

| Reagent Capacity | Up to 48 reagents |

| Connectivity | LIS (Laboratory Information System) Interface |

| Operating Temperature | 15°C to 30°C |

| Operating Humidity | 20-80% (non-condensing) |

Explains the printed and visual cues used to guide the user in responding to printed directions.

Describes the manual format, including modular units and procedure tables.

Summarizes hazards associated with the DxC System, including bar code reader, biohazardous materials, and electric shock hazards.

Lists precautions for operating the DxC System, covering sensors, filters, buffers, calibrators, and bar code labels.

Lists and describes symbols and labels used on the DxC Systems components, including power switches and connectors.

Details the major components of the UniCel DxC System, including Sample Handling, Modular Chemistry, and others.

Explains the microprocessor-controlled, random access analyzers and their operational theories.

Describes calibration principles for cartridge chemistries, including endpoint, first-order, and non-linear types.

Explains calibration for modular chemistries, including error detection and methodology.

Explains spectrophotometric methods and Beer's Law as principles of measurement for cartridge chemistries.

Details identifying samples, selecting tests, describing samples, and programming how to run them.

Covers minimum sample volume requirements and sample rack compatibility.

Provides guidance on recommended use of reserved racks and when not to use them.

Explains the use of bar code labels for sample identification and processing accuracy.

Describes how to add tests to an existing sample program or rerun a sample.

Outlines the steps to clear sample programming, rack/position, or by date/time.

Allows assigning user names, passwords, and privileges, and managing system security.

Covers enabling/disabling automatic overrange detection and correction (ORDAC) and serum index functions.

Explains how to configure the chemistry menu, including adding, deleting, and defining print names.

Details setting analytical, instrument printable, and operator-defined reportable ranges.

Allows defining normal and critical ranges for analytes by age group, gender, and sample type.

Covers enabling/disabling sample bar code modes, types, and parameters.

Manages CTS option, obstruction detection, and assigning reserved racks for specific sample types.

Allows changes to hardware configuration, data logger IP, and Ethernet addresses.

Explains how to load new versions of chemistry database software, updating or adding chemistries.

Describes how to load reagents onto the DxC 800/600 systems and calibrate chemistries.

Explains system calibration to standardize sample analysis, covering required conditions and options.

Details pop-up messages and explanations for calibration failures in CC and MC subsystems.

Covers multiple reagent loads of the same lot number without recalibrating each cartridge.

Allows overriding a failed calibration to obtain results based on the failed calibration factors.

Permits continuation of analysis of other programmed tests after a calibration failure.

Allows editing programmed calibrator set points to alter chemistry provided it meets specific criteria.

Details adjusting the slope (m) or y-intercept offset (b) of the regression equation for results calculations.

Provides capability for monitoring system and chemistry performance through real-time control data analysis.

Explains the Z-score method for standardizing measurements and flagging results based on deviations.

Details Westgard rules utilized for evaluation of QC data, including 1-2S, 1-3SD, and 2-2S rules.

Allows operators to define up to 100 controls, specifying name, lot number, QC file number, and sample type.

Covers defining up to eight bar codes (control IDs) per control for sample programming and processing.

Describes how to run control samples with or without bar code labels, including auto generation.

Details editing assigned mean, SD, constituent code, and bar code IDs of a previously defined control.

Explains how to review control definitions from current or archived QC data.

Covers archiving control definition, log, and results to a floppy disk for data review and modification.

Details verifying rack status and sample carousel status before programming and assignment.

Explains sample identification using Sample ID or rack/cup position, including limitations and valid characters.

Describes manual test selection methods, including panels, configuration numbers, and chemistry buttons.

Covers entering dilution factors and programming Manual Overrange Detection and Correction (ORDAC).

Details programming multiple samples with identical parameters, including identification and status.

Allows recalling patient and control results by individual or range of Sample IDs, with output options.

Enables recalling results by rack number and position, with options for series and range entry.

Allows recalling results by Patient ID, with output options for viewing, printing, or sending to host.

Details how to view recalled results on the screen, including navigating pages and updating data.

Describes deleting one of two results for a sample rerun with Critical Result Rerun.

Explains how to print recalled results in default or multi-sample report formats.

Covers recalling and sending whole data parcels or individual results to the host computer.

Allows generating a report with mean, Standard Deviation, and Coefficient of Variation for selected samples.

Outlines minimum operating parameters and precautions for using User-Defined Reagent feature.

Guides through defining and editing user-defined reagents, including parameters and limits.

Covers defining test names, reaction types, units, precision, reaction direction, and math models.

Explains selecting primary and secondary wavelengths for measuring analyte absorbance.

Provides methods for determining molar absorptivity or extinction coefficient 'e' for analysis wavelengths.

Specifies parameter requirements for correctness, completeness, and consistency of chemistry protocols.

Details the process of clearing a user-defined reagent from the system and chemistry menu.

Provides an overview of maintenance for optimal performance and reduced service calls.

Covers routine checks and cleaning tasks performed weekly for optimal system performance.

Details tasks performed monthly, including reagent replacement and module cleaning.

Covers replacement of CTS blade/wick and cleaning/changing air filters.

Includes replacement of syringe plungers and priming procedures.

Details cleaning of MC reagent lines, cups, and stir bars.

Covers replacing Calcium and Potassium electrode tips, and the glucose sensor.

Provides procedures for maintenance tasks performed on an as-needed basis for system performance.

Details replacement of the Cap Piercer wick and blade assembly for CTS systems.

Provides a high-level summary of system status, including temperatures, power, and components.

Approximates instrument usage and aids in estimating maintenance frequencies or component failure.

Shows actual temperatures of components, valid ranges, and indications of out-of-limit parameters.

Displays status of power supplies, voltage, peltiers, and fans, highlighting warnings or errors.

Shows status of reservoirs, canisters, and sumps, including air/vacuum pressures and DI water resistivity.

Monitors power to Smart Modules and their communication ability, indicating errors or warnings.

Shows absorbance values for cuvettes from water blank tests, indicating clean or dirty status.

Ensures sample tubes are pierced only once, operating on networked DxC instruments.

Lists high-level system commands for controlling instrument and printer operations.

Moves mechanical assemblies to a known position and primes the system for recovery or standby.

Prevents new tests from starting without wasting sample or reagent, pausing MC, CC, or both sides.

Stops print requests in the queue, useful for preventing multiple print requests or large reports.

Places the system into a safe state for reset or power off, closing system files to prevent data corruption.

Describes the boot-up sequence, including hardware diagnostics, module booting, and system priming.

Allows enabling or disabling individual subsystems, MC side, or CC side for operation or error conditions.

Removes all sample racks from the sample carousel to the offload track when instrument is in Standby or Stopped.

Permits manual request for priming entire subsystems or individual components for system readiness.

Provides routine instrument cleaning and part replacement for optimal performance.

Records events and errors for troubleshooting, allowing viewing, printing, or copying to disk.

Details copying Events to a disk, creating a file for word processing or sending to Beckman Coulter.

Removes unwanted event information from selected classes or the entire Event Log.

Includes tests for confirming instrument problems, adjusting components, and assessing performance.

Enables storing data to a floppy disk for backup and restoring previously backed-up data.

Adjusts the system for correct screen touch selection, especially after monitor movement or installation.

Covers calibration reports, error flags, and checks for linear, non-linear, and MC calibrations.

Details MC calibration using calibrator levels, including checks like back-to-back, range, and DAC.

Explains linear calibration based on replicates, including checks for back-to-back, range, and span.

Describes calibration for non-linear chemistries, including checks for curve fitting and multipoint spans.

Explains how reactions are checked against parameter limits and how errors are flagged.

Provides descriptions for various error codes and their meanings in result reporting.

Lists common system error messages, pop-up text, event log entries, and corrective actions.

Loading...

Loading...