VDL (E3) 09/2019 Page 36/234

2.6 Standard Operating Procedures (SOPs)

The operator is responsible to determine the correct auto-ignition temperature of the solvent. To ensure

this, creating Standard Operating Procedures (SOPs) is recommended.

In particular, this should prevent the Residual Risks due to incorrect operation specified in Chap. 1.11

and the exceeding of the auto-ignition temperature of the solvent.

When creating Standard Operating Procedures, take into account the information and instructions in this

Operating Manual. The following are some examples of these risks and suggestions for measures to be

taken. These are to be created, adapted, and supplemented by the operator using the risks determined

and respective conditions at the installation site.

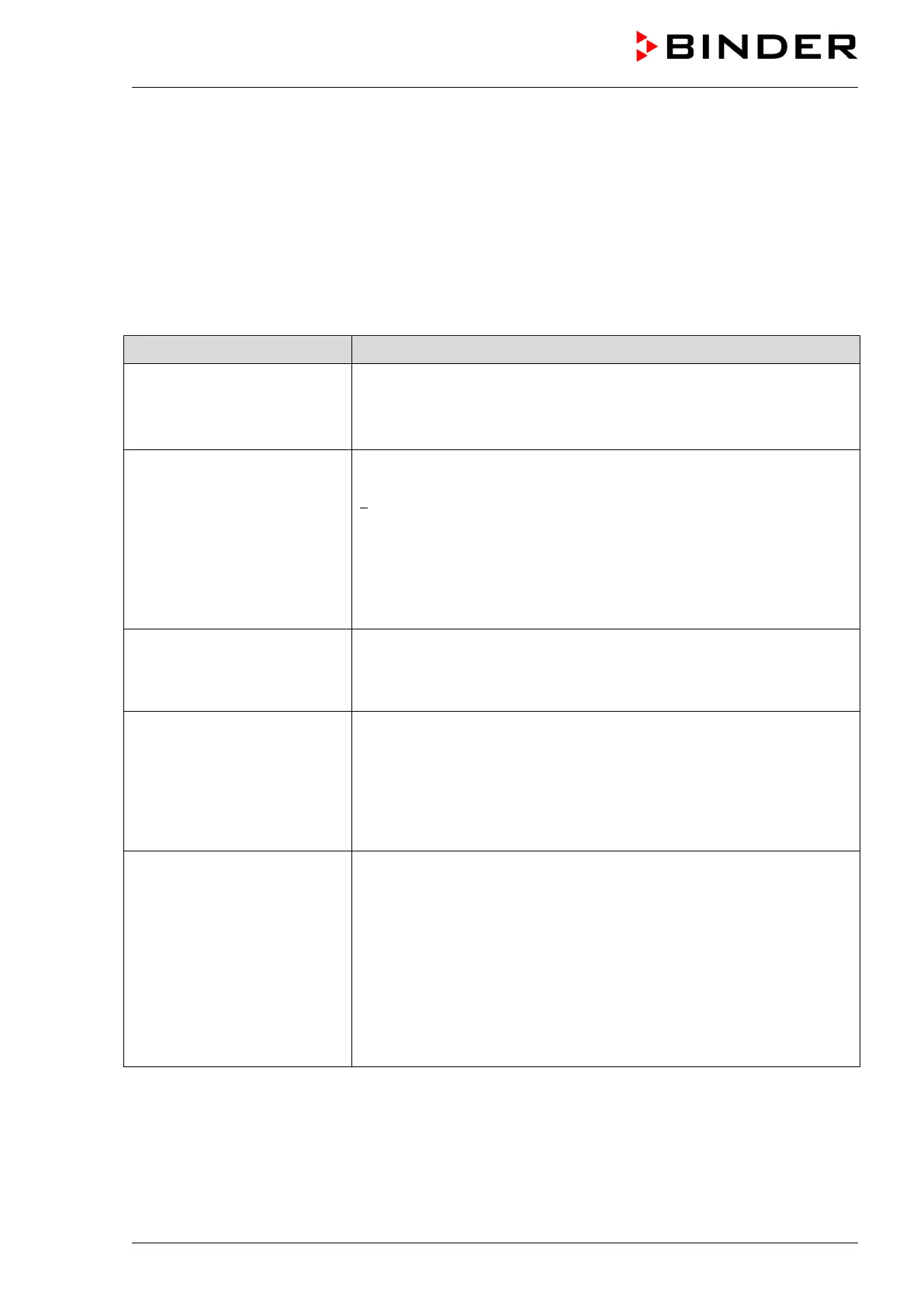

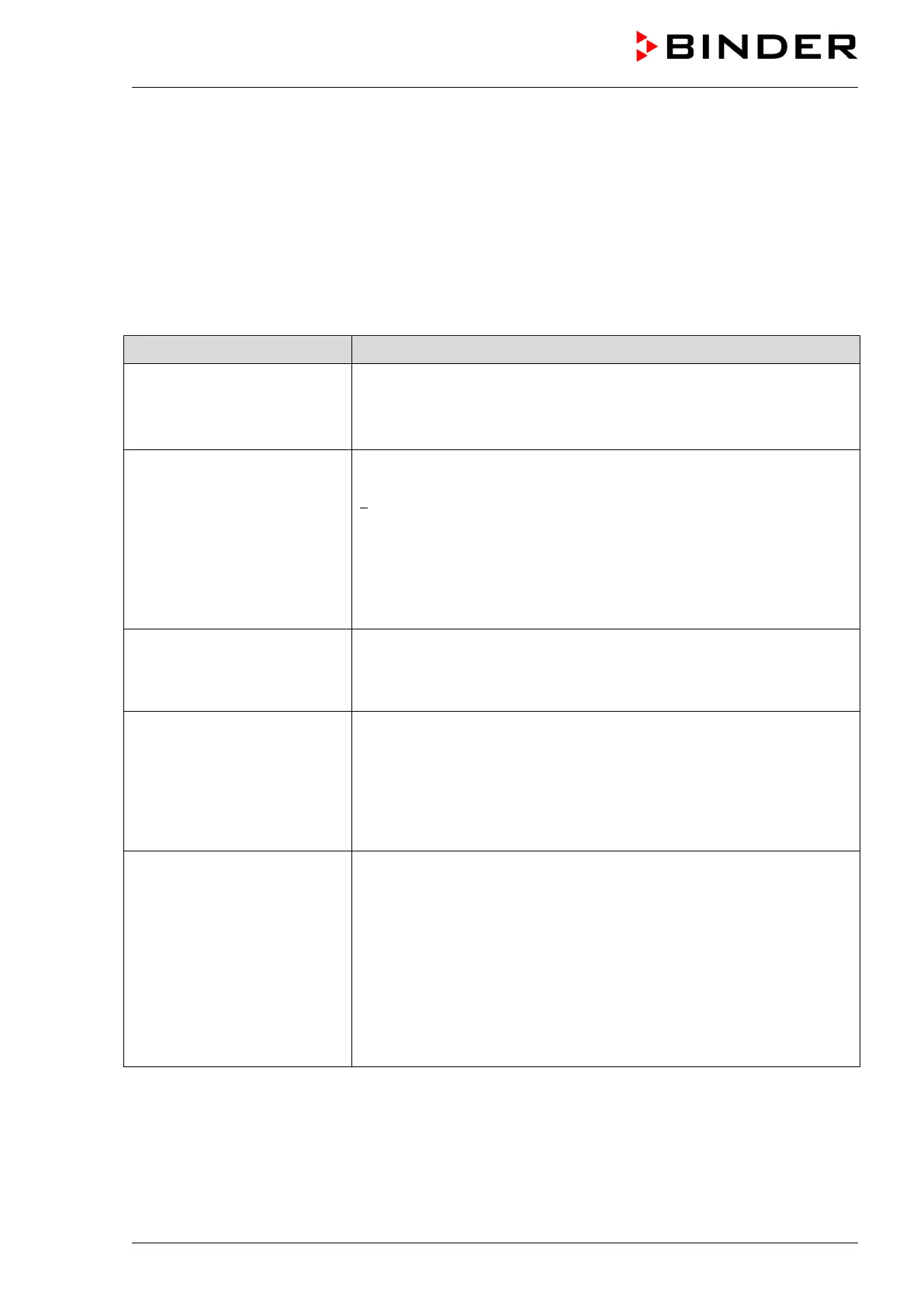

Risk Measures

Operation of the device by

untrained users

• Ensure knowledge of the Operating Manual

• Use only ATEX-trained personnel

• Create operating instruction and standard operating procedures

Use of an unsuitable solvent

with a too low ignition tempe-

rature

Cause: Assumption of wrong

solvent

• Prior to each new drying procedure check again the auto-ignition

temperature with the safety specifications.

•

Clearly label the material to be dried to avoid confusion

Information: There is no risk during the proper drying process, since

this takes place in a vacuum. There is only a risk in the event of prema-

ture air supply (termination of the drying process.

• Avoid premature air supply. Also observe the instructions in the

Operating Manual.

Reloading with the a material

with a lower auto-ignition tem-

perature

• Prior to each new drying procedure check again the auto-ignition

temperature with the safety specifications and the desired drying

temperature. If appropriate, let the chamber cool down before reloa-

ding

Occurrence of a zone outside

the specified area (see Chap.

3.6)

Cause: operating error (e.g.

Falling of the loading material

or of the filled condensate

catchpot of the pump)

• Make sure that the chamber is always disconnected from the power

supply when emptying the condensate catchpot .

• Switch off chamber immediately : disconnect the power plug or use

the customer's explosion-protected emergency stop switch

Termination of the drying pro-

cess due to inadmissible sol-

vent with a too low ignition

temperature.

Ventilation with ambient air or

opening the still hot chamber

Cause: 2 operating errors:

incorrect loading with an in-

admissible solvent; improper

Termination of the drying pro-

cess

• Disconnect the power plug and turn off the pump.

• Let the chamber cool down to room temperature.

• Do NOT remove the “Manual ventilation” plug.

• Only ventilate when the interior temperature has cooled to room

temperature. Only then open the door.

Loading...

Loading...