VDL (E3) 09/2019 Page 91/234

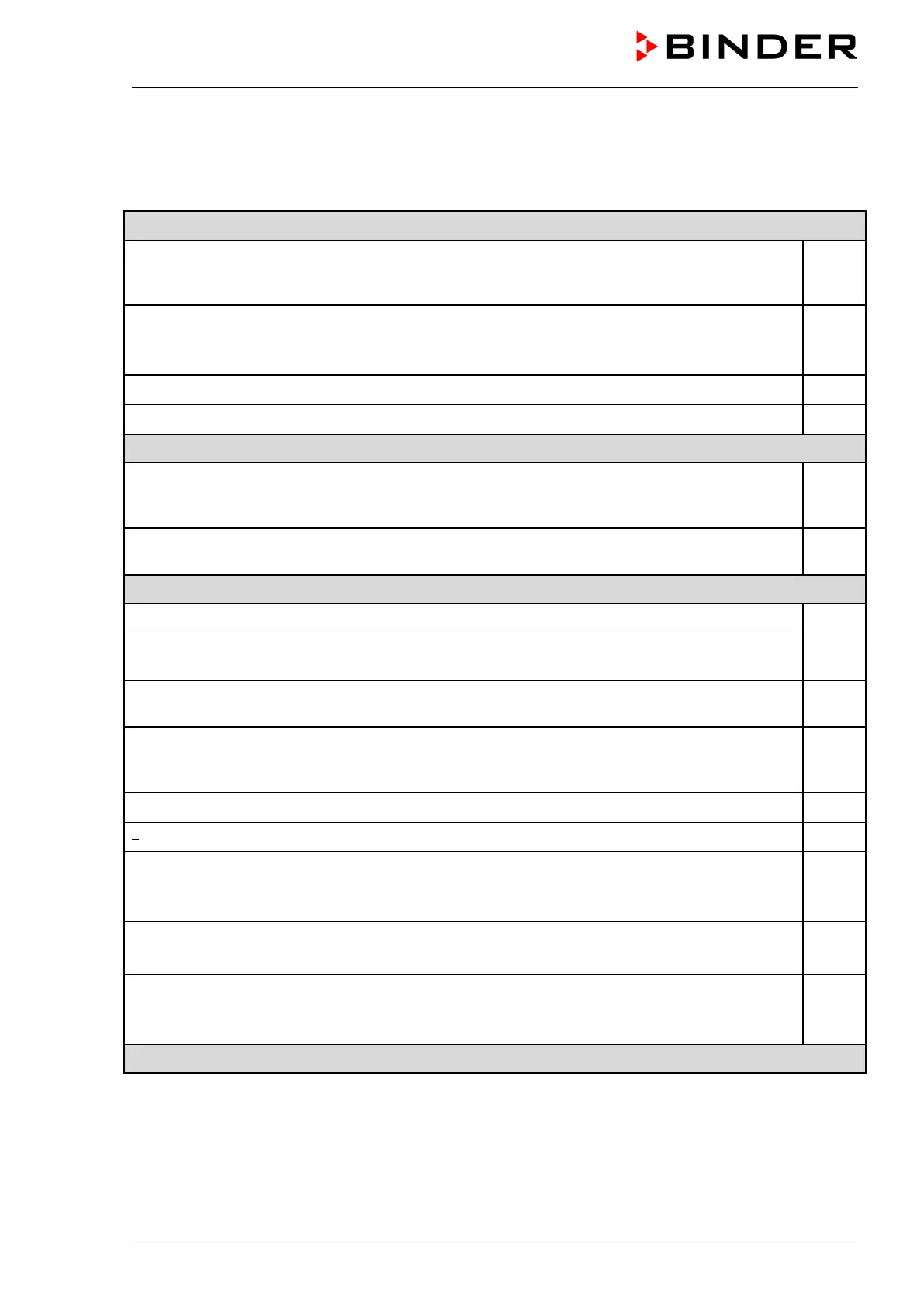

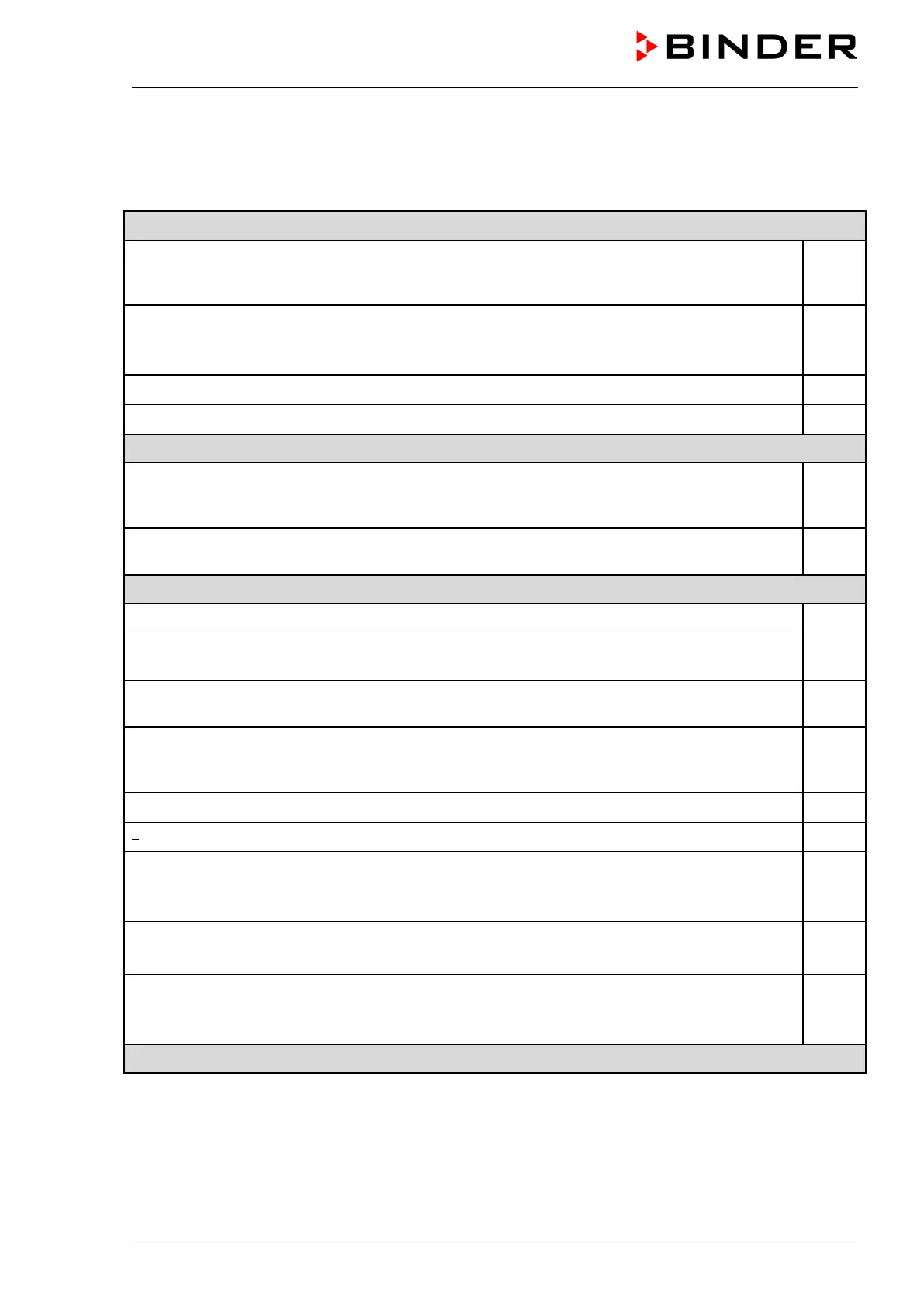

9.2 Overview of the drying process

Required measures for operation with solvent-containing substances, which may be able to form an ex-

plosive mixture with air:

Starting situation

• The vacuum drying oven and additional equipment have been set up and installed in ac-

cordance with the instructions in this manual, the instructions of the operator and the relevant

regulations. Equipotential bonding according to the grounding concept is ensured

□

• The auto-ignition temperature of the solvent has been determined from its safety specifica-

tions

In the case of solvent mixtures, use the lowest auto-ignition temperature.

□

• All users have been trained and are familiar with the safety plan and the required measures.

• The vacuum source is connected and ready for operation

Sweeping the area for electrical equipment and the triangle instrument box

• Open the pressure regulator on the chamber rear for sweeping the electrical installation

space and conttroller housing and adjust it by checking the manometer so that there is at

least 25 Pa overpressure

□

• Sweep the area for electrical equipment and the triangle instrument box with compressed air

or inert gas for at least 15 minutes

□

Loading and starting the drying process

• Make sure that the technical ventilation is activated

• Make sure that equipotential bonding has been established according to the grounding con-

cept

□

• Make sure that the sweeping time of 15 minutes for the electrical installation area and con-

troller housing have been observed

□

• Make sure that the compressed air or inert gas supply for sweeping the electrical installation

area and controller housing is still open. Check the excess pressure of at least 25 Pa on the

manometer,

□

• In case of Standby mode turn on the vacuum drying oven on the controller

• Set the desired temperature setpoint on the controller.

• Set the safety controller to a suitable value.

Recommended setting: safety controller mode:Limit, safety controller value approx. 5 °C

übabove the temperature set-point

□

• Make sure that the user's equipment is ESD protected.

• Place the material to be dried in the chamber.

□

• Set the pressure set-point on the controller.

Heating will start only when a vacuum corresponding to the pressure threshold of 100 mbar) is

reached.

□

The drying process is running.

Loading...

Loading...