VDL (E3) 09/2019 Page 60/234

DANGER

Risk of suffocation due to high concentration of inert gas.

Death by suffocation.

∅ Do NOT set up chambers in non-ventilated recesses.

Ensure active technical ventilation measures.

Respect the relevant regulations for handling inert gas.

When decommissioning the vacuum drying oven, shut off the inert gas supply: Close

valve (6).

6.2.1 Setting the overpressure for sweeping with compressed air / inert gas

After opening the pressure regulator on the chamber rear (turn clockwise), the area for electrical

equipment of the oven and the controller housingwill be swept. Compressed air or inert gas is used and

then released into the surrounding atmosphere independent of the oven’s operating state.

Compressed air sweeping must be in operation for at least 15 minutes before turning on the chamber. It

remains in operation during the entire use of the chamber (loading, drying, removal of the material to be

dried), with an overpressure of at least 25 Pa (recommendation: 40 Pa).

On the chamber front there is an analog pressure display (manometer) to show the existing overpressure.

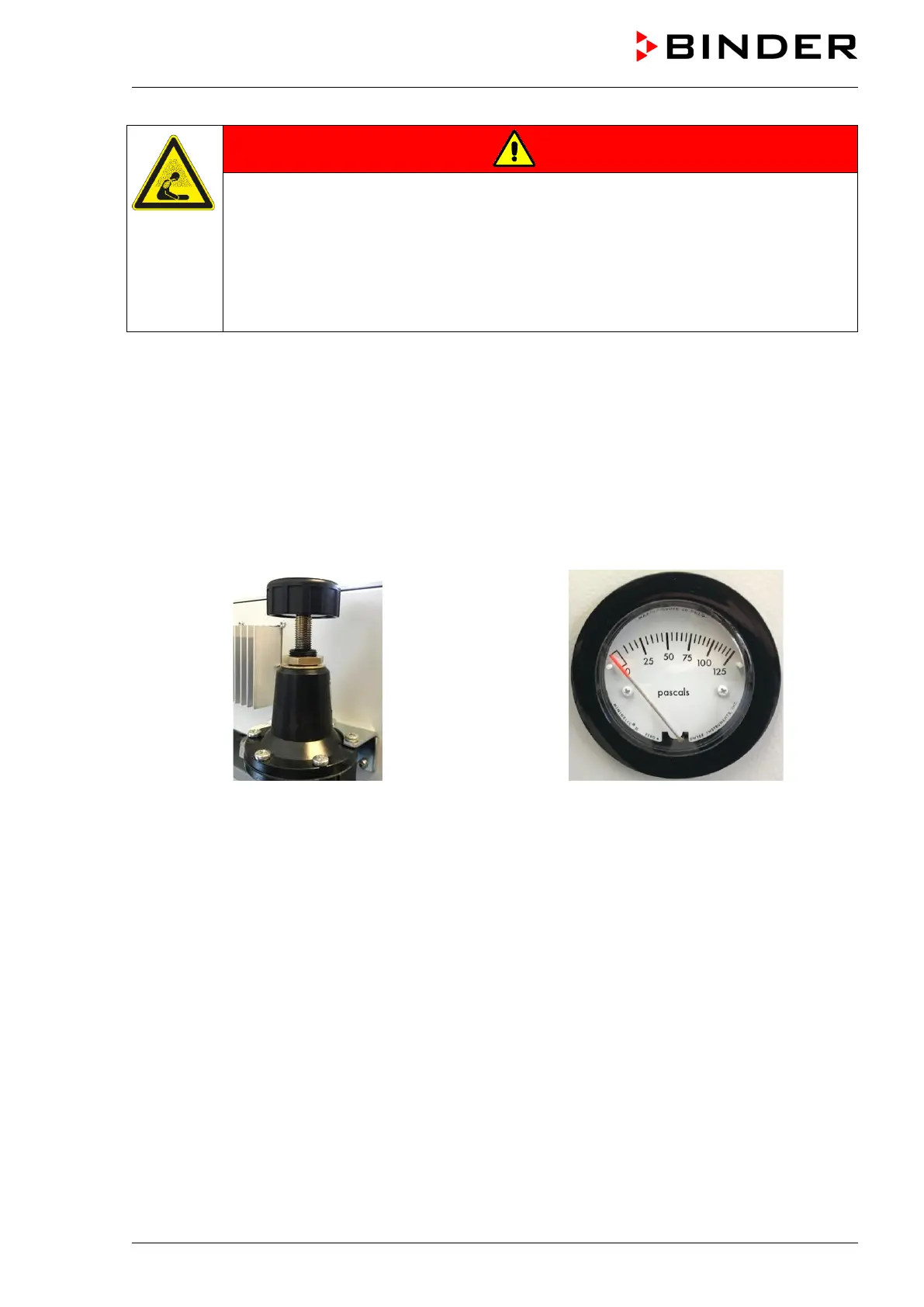

Figure 14: Pressure regulator for compressed air

sweeping on the chamber rear, top right

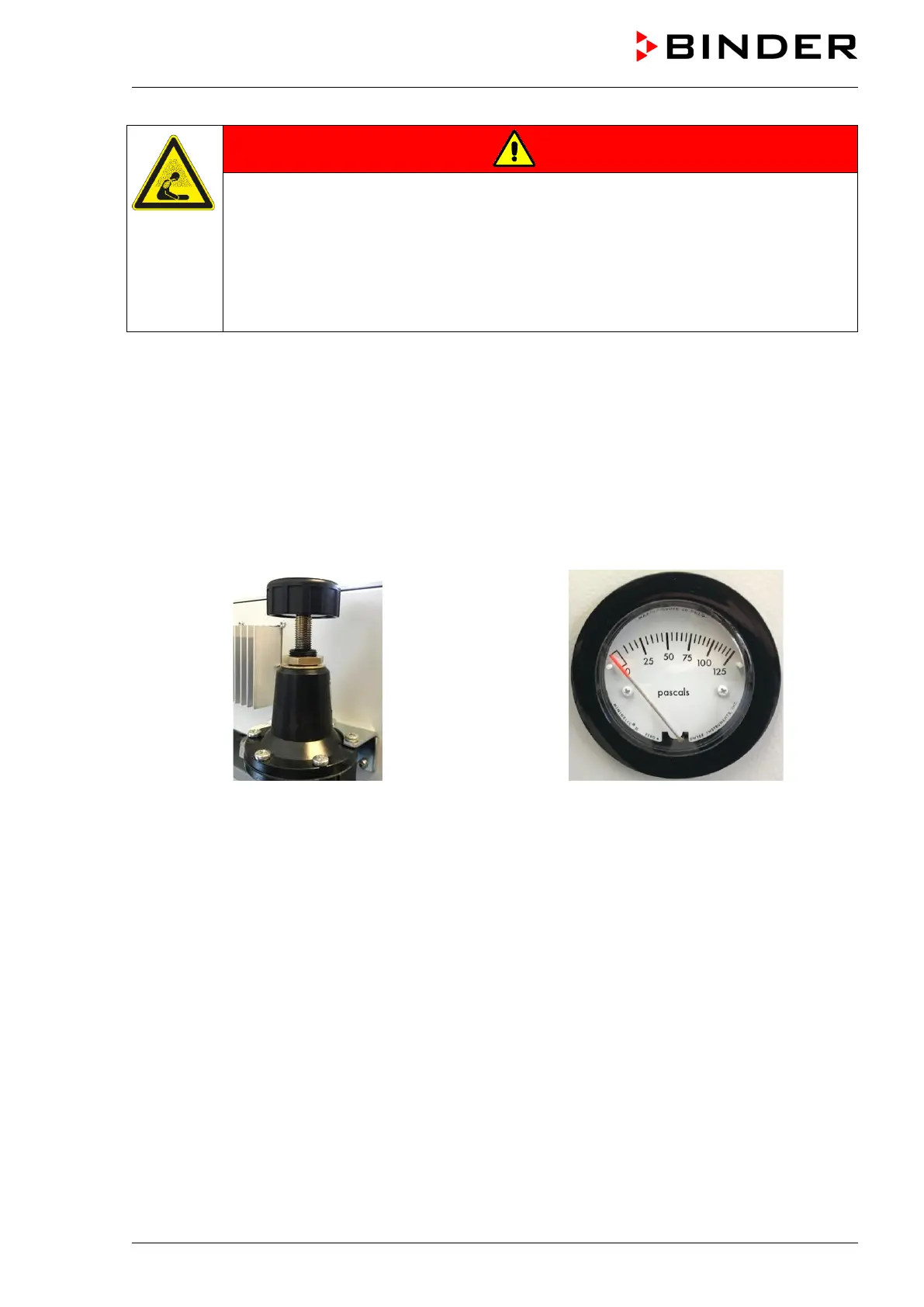

Figure 15: analog pressure display (manometer)

for compressed air sweeping on the chamber front

Sweeping before starting up the chamber:

• Open the USB cover on the triangle instrument box

• Turn the pressure regulator until the end stop to the lock nuts (turn clockwise).

• Recommended time for sweeping 15min. This flushes 5 times the volume of the electrical installation

area and controller housing

• Close the USB cover on the triangle instrument box.

• Now the pressure regulator can be turned back (turn counterclockwise) until there is an overpressure

of at least 25 Pa (recommendation: 40 Pa).

Sweeping during chamber operation:

• Set the pressure on the pressure regulator in a way that the manometer shows at least 25 Pa over-

pressure. Recommended value: 40 Pa.

• Check the display frequently during chamber operation. In all operating states, the value on the ma-

nometer must indicate > 25 Pa.

• The USB cover on the triangle instrument box must be closed.

Loading...

Loading...