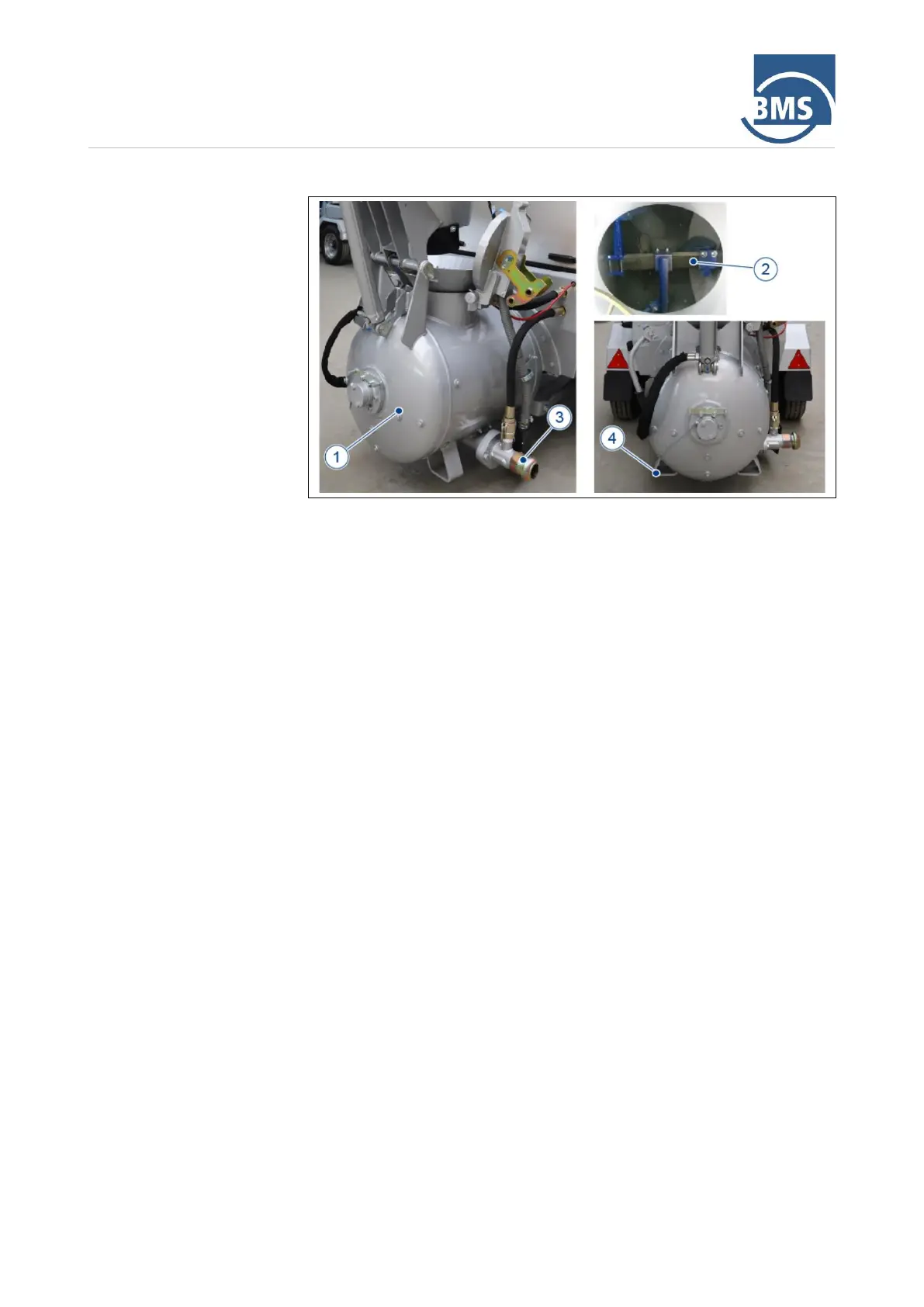

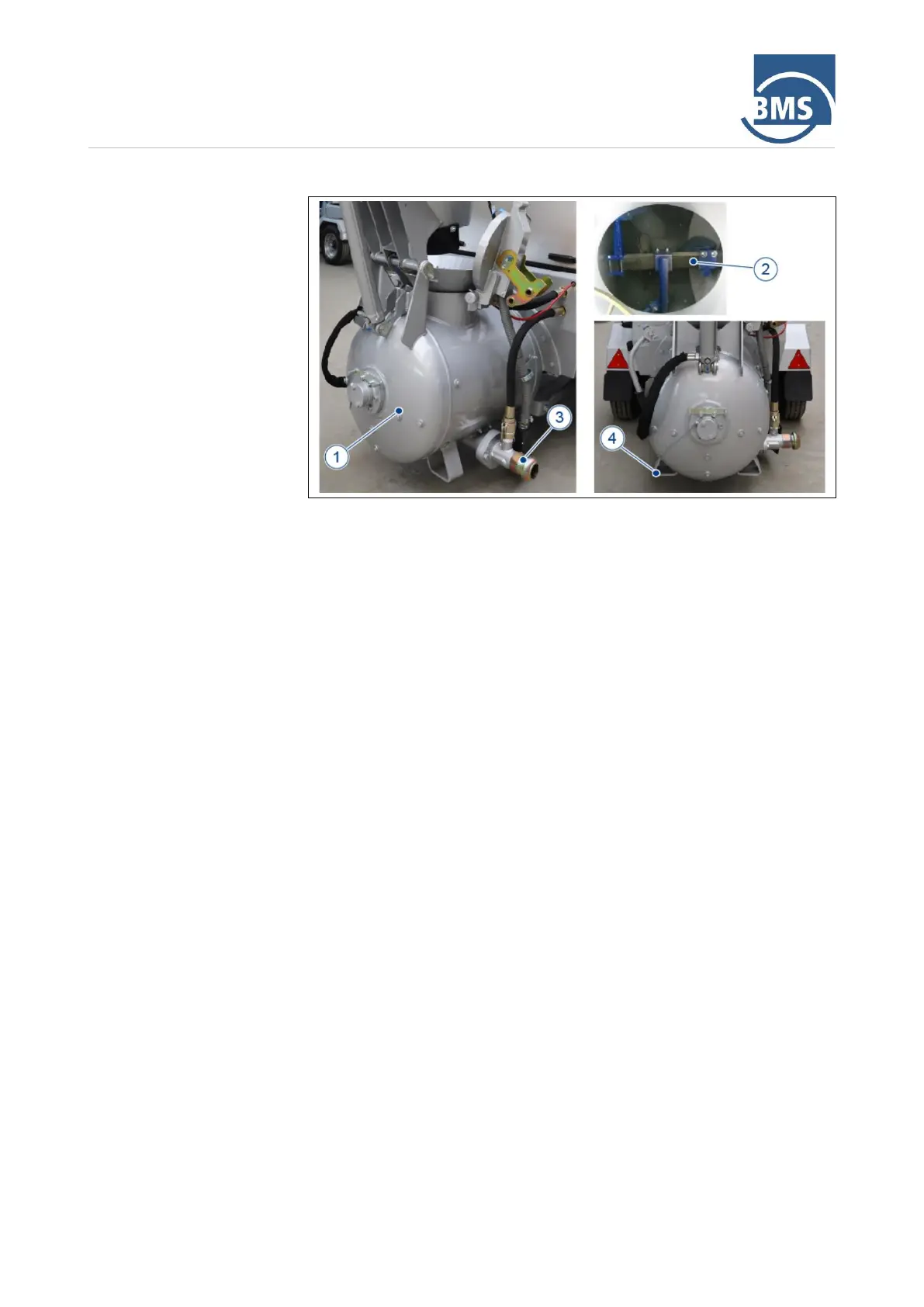

The building material is mixed in the mixing and delivery vessel (1), with the

pressure vessel being operated as a compulsory mixer.

The lateral openings on the vessel serve to accommodate the mixing shaft

(2), the mixing shaft bearing and the seal. The mixing shaft is equipped with

mixing blades for mixing the material to be conveyed (mix). The mixing shaft

blades convey the mix into the delivery hose, which is connected to the

connection (3), after pressure has been applied in the vessel. The delivery

capacity can be further increased by means of the selectable power mode.

The mixing shaft is driven by the diesel motor via a pulley and gearbox. The

mixing time is set individually via the automatic mixing time control before

starting the pumping operation (after switching on the machine).

At the rear of the mixing and delivery vessel there are two vessel feet (4),

which ensure that the BMS alpha

CR

stands firmly when the support wheel is

correctly adjusted.

Loading...

Loading...