145

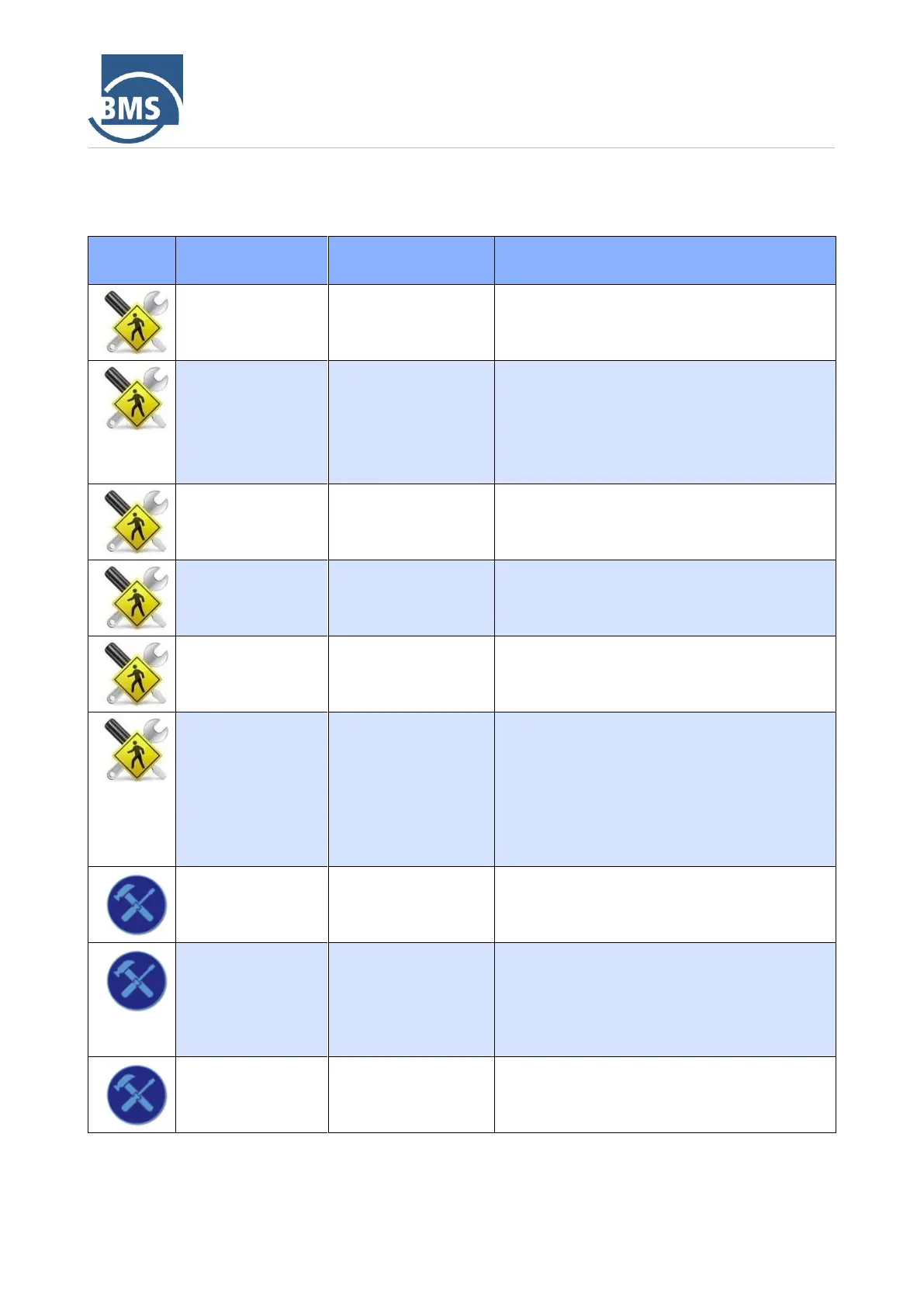

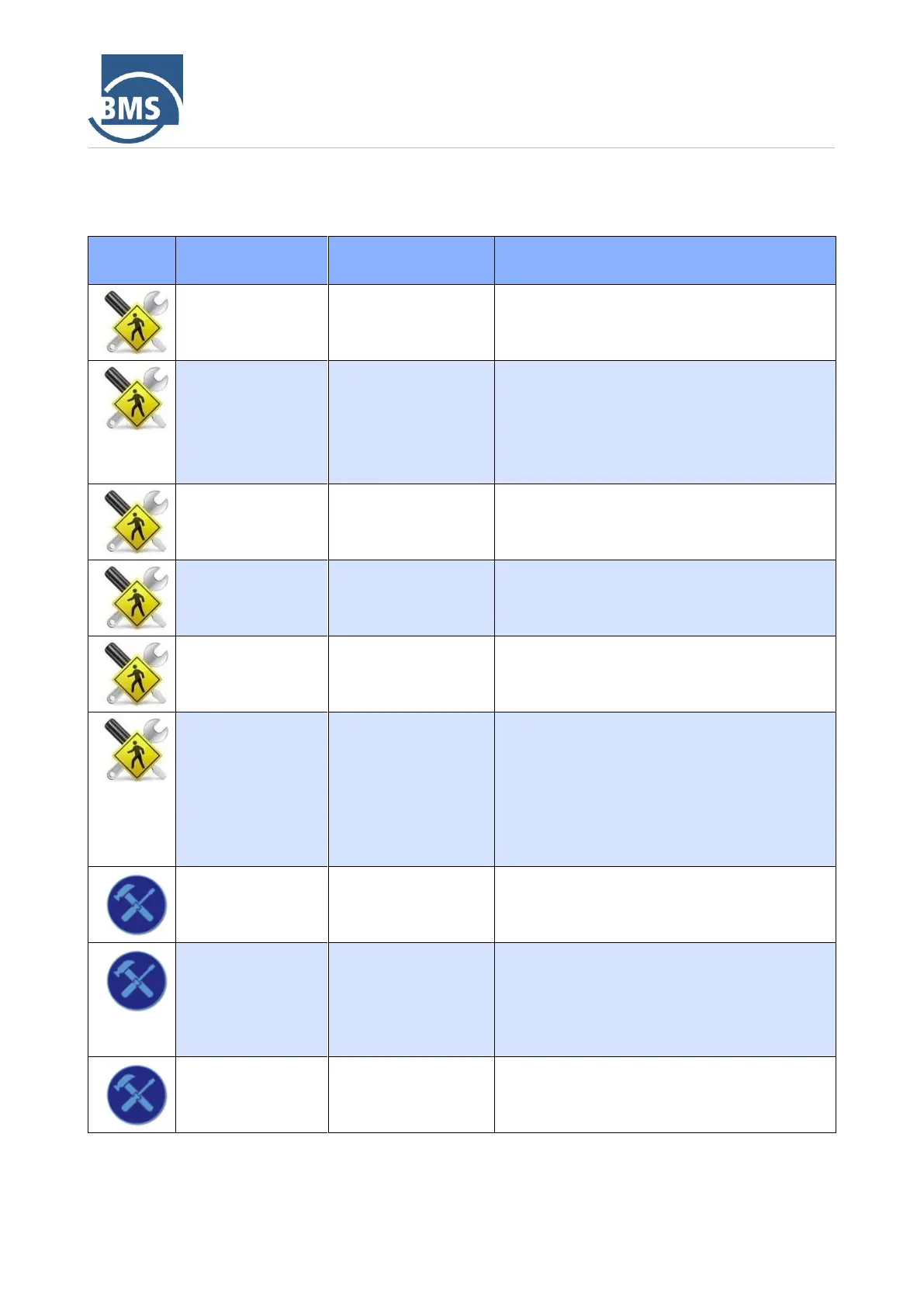

10.5.2 Maintenance schedule machine

Regular maintenance

Check gas

adjustment control.

Check air filter for the

following

components:

− motor

− compressor.

Clean the motor air filter and compressor air

filter as required, replace if necessary.

Note:

Never clean filters with compressed air!

Filter change every 500 operating hours.

Check fuel prefilter

and fuel filter.

Check fuel prefilter and fuel filter and renew if

necessary.

Filter change every 500 operating hours.

Check motor oil filter and replace if necessary.

Filter change every 500 operating hours.

Check compressor oil

filter.

Check compressor oil filter and replace if

necessary.

Filter change every 500 operating hours.

Check air deoiling

device.

Check air deoiling device and replace if

necessary.

Note:

Always replace the seal between the cover and

the tank housing!

Replace the air deoiling device every 1000

operating hours.

Check the function of

safety and protective

devices

All safety devices must be installed and

functional.

Visual inspection of

the entire machine for

defects.

Pay particular attention to the following points:

− Corrosion.

− Seals.

− Cables and wiring.

Check the lock and

securing of the hood.

The hood may bounce during travel. During

operation, an open hood can lead to insufficient

cooling and thus to damage to the machine.

Loading...

Loading...