Operating Instructions ACTIVE06/07 155

06/07 Operating Instructions ACTIVE 155

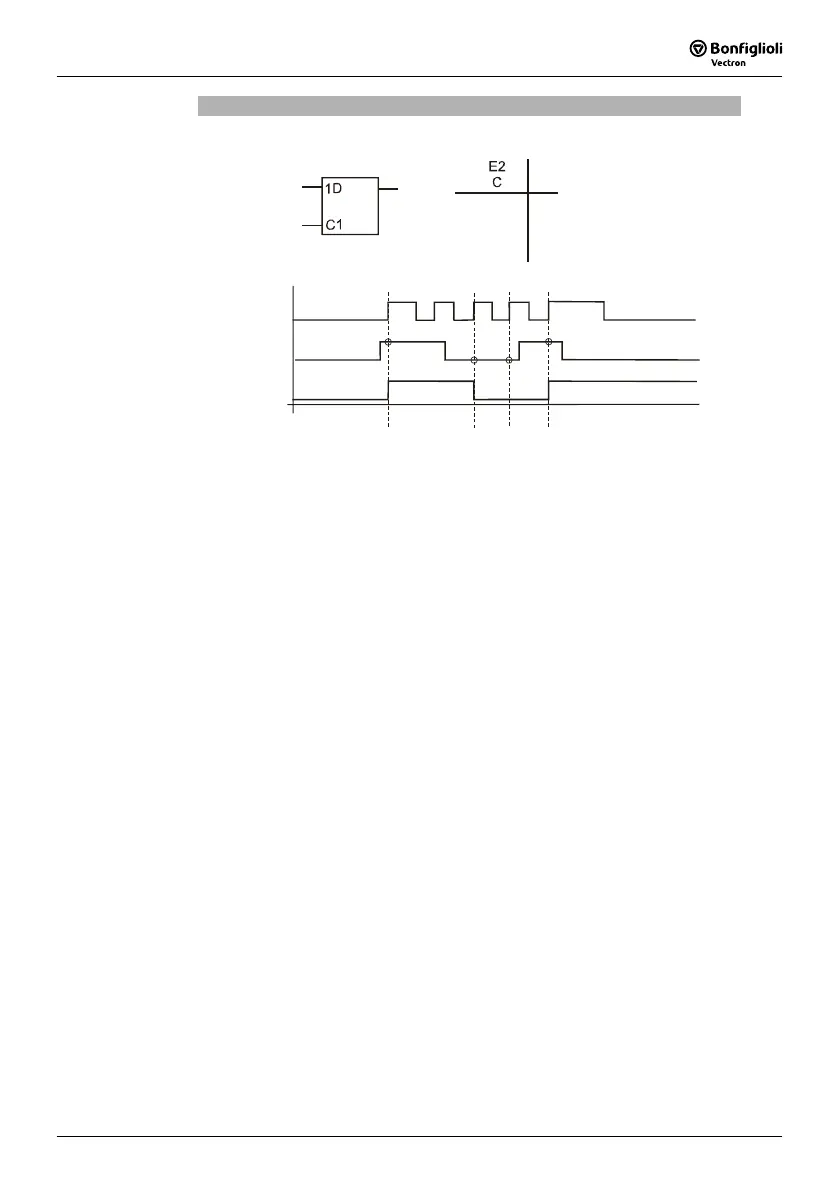

D Flip-Flop

Parameter

Operation Mode Logic = 30

Q

E2; C

E1; D

E1; D

E2; C

Q

E1

D

Q

0

1

0

1

0

0

0–>1

0–>1

Q

n-1

Q

0

1

n-1

Status

hold

sample

hold

sample

E1: data input D; E2: clock input C; Q: output

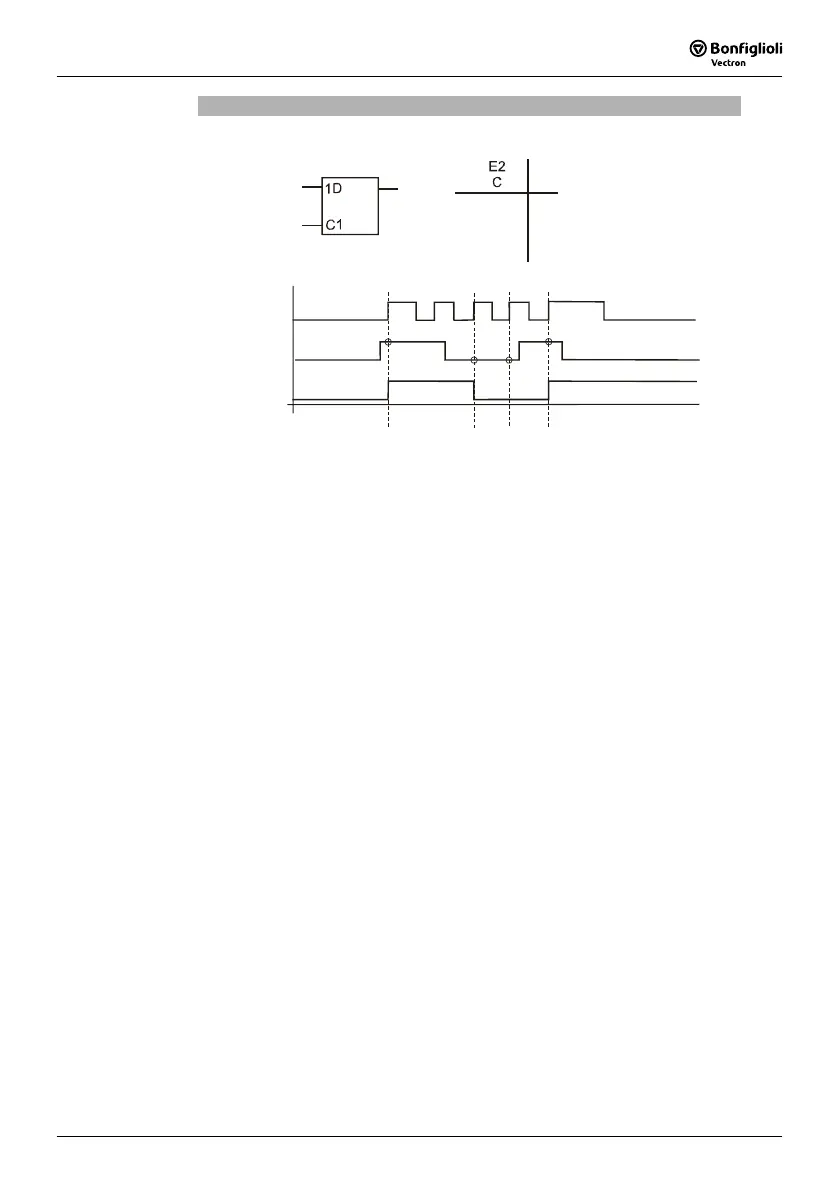

If logic "0" is present at input 2 (clock input C), the previous logic state is maintained

at the output independent of the status of input 1 (data input D).

If a positive clock edge is received at clock pulse input C, the signal present at data

input D is transmitted to the output. The output maintains its state Q

n-1

until the next

positive clock edge is received.

If a negative clock edge is received, the output signal remains unchanged.

Loading...

Loading...