The NMR Sample

52 / 86 H171804E_14_001

7.2 Sample Tube

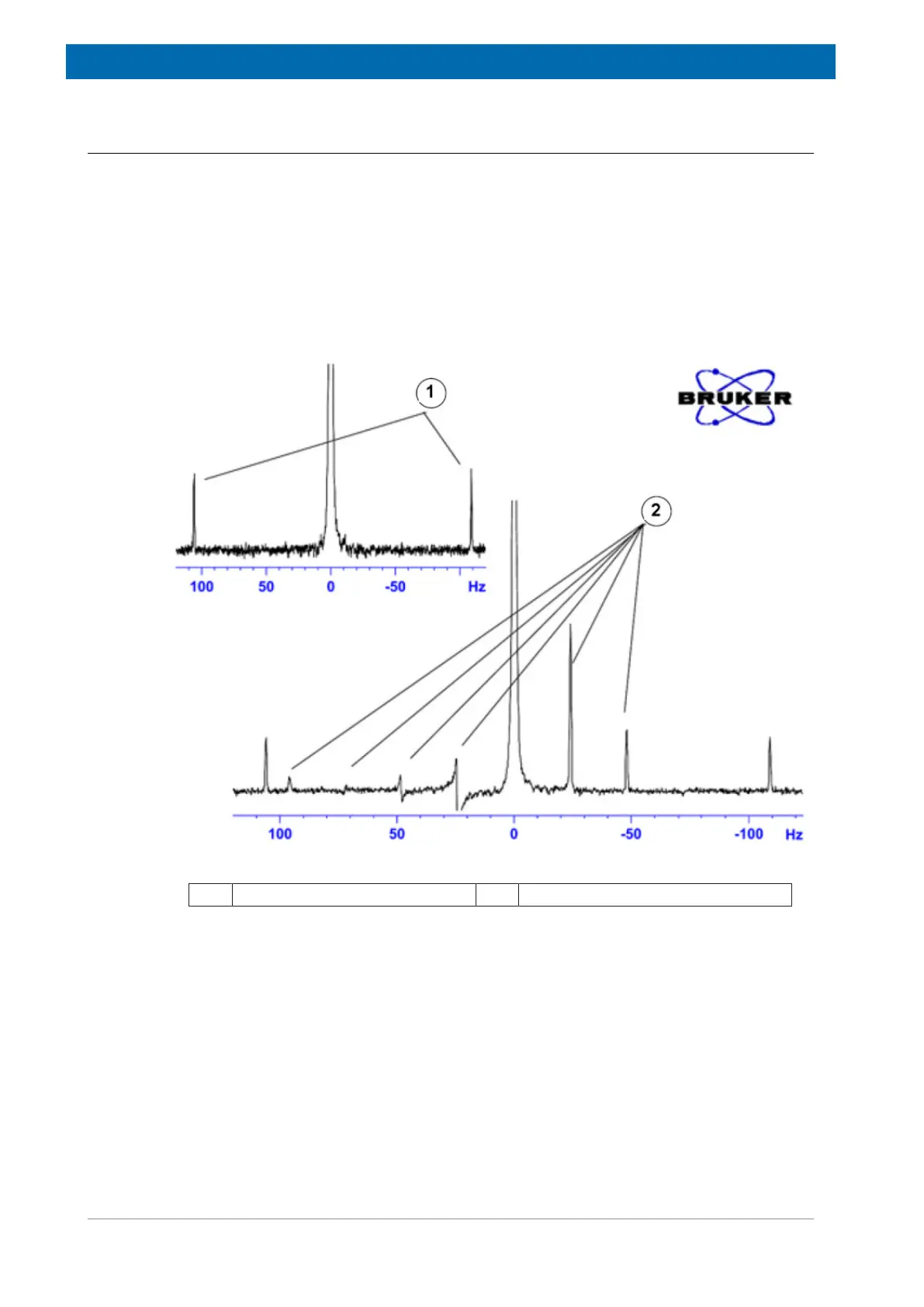

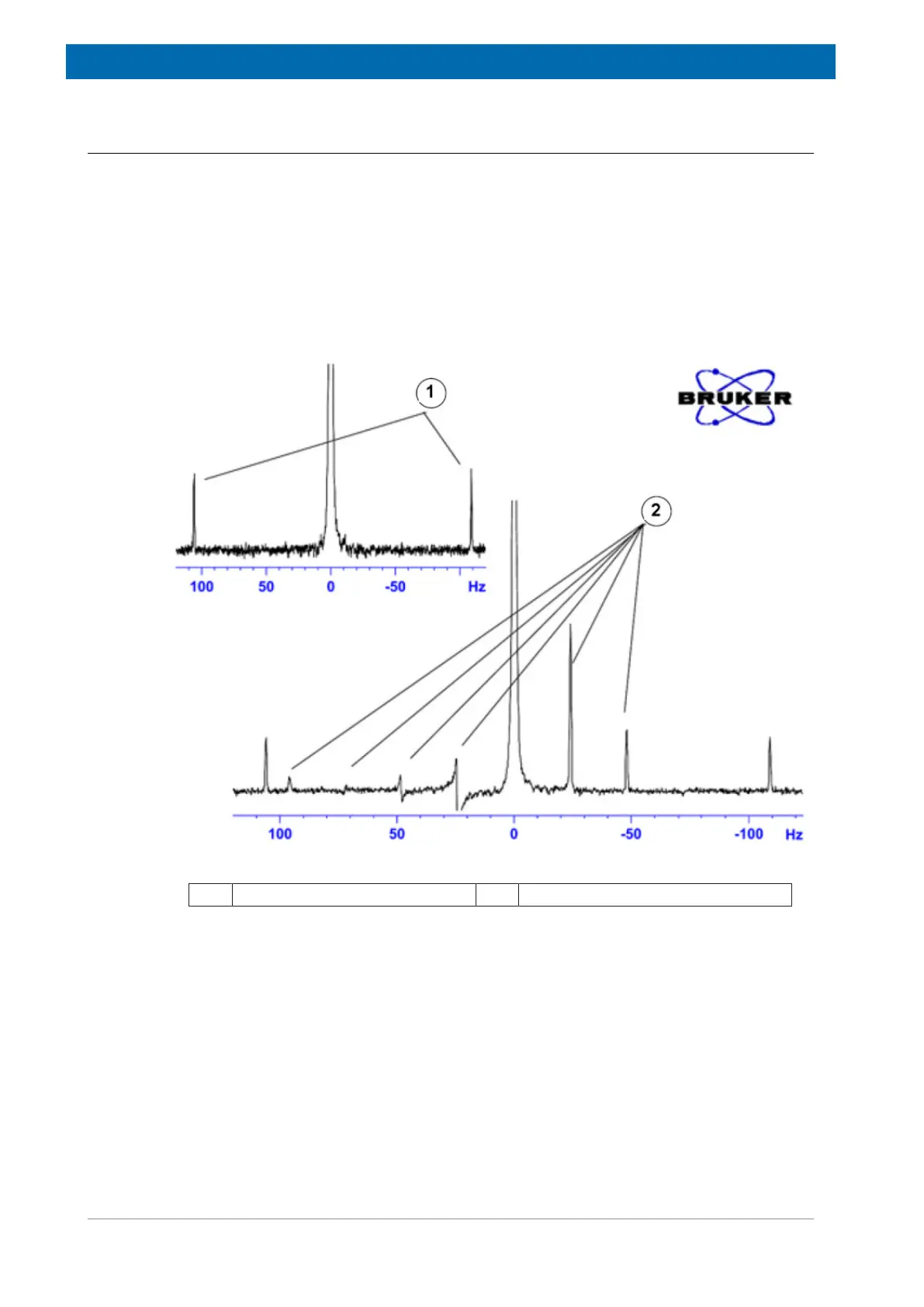

When the sample is being analyzed it may be rotated, depending on the type of probe or

experiment. Spinning the sample has the effect of cancelling out field inhomogeneities in the

X and Y direction and consequently improves the spectral resolution. A disadvantage of

spinning is that it may lead to the presence of spinning sidebands. These are spurious

signals (i.e. peaks) that result from the modulation of the magnetic field at the spinning

frequency. The peaks always appear on either side of any large genuine peak at a separation

equal to the spinning rate. The intensity of these sidebands will be proportional to the

intensity of the genuine peak. Thus if the spin rate is 20 revolutions/second (= 20 Hz), you

would look for spinning side bands at frequencies 20 Hz above and below the resonance

frequencies of genuine signals.

Figure7.1: Spectrum Showing Spinning Sidebands

1. 13C Satellites 2. Spinning Sidebands

While the presence of spinning sidebands may be inevitable, their size often depends on the

sample tube quality. Ideally, the sample tube should have perfect cylindrical symmetry.

Unusually large sidebands might suggest that the tube symmetry is inadequate and might

warrant using tubes with higher specifications (and of course greater cost).

Sample tubes must always be kept clean and free from dust and scratches. Do not scrub the

tubes with test tube brushes. Be aware that new NMR tubes cannot be assumed to be clean.

The tubes may be cleaned by washing in Acetone or distilled water. Liquid detergent may be

used as long as it is rinsed out within a few minutes to prevent etching of the tube. The tubes

may also be cleaned ultrasonically in an appropriate solution. If all the above measures fail,

the tubes should be soaked in AQUA REGIA for up to two days and then rinsed thoroughly

before being dried. NMR tubes can be oven dried but should not be heated above 100°C as

they can become distorted and subsequently fail to spin as required. Drying is best achieved

by passing filtered nitrogen through the tube.

Loading...

Loading...