138 - 8630

DEVICENET

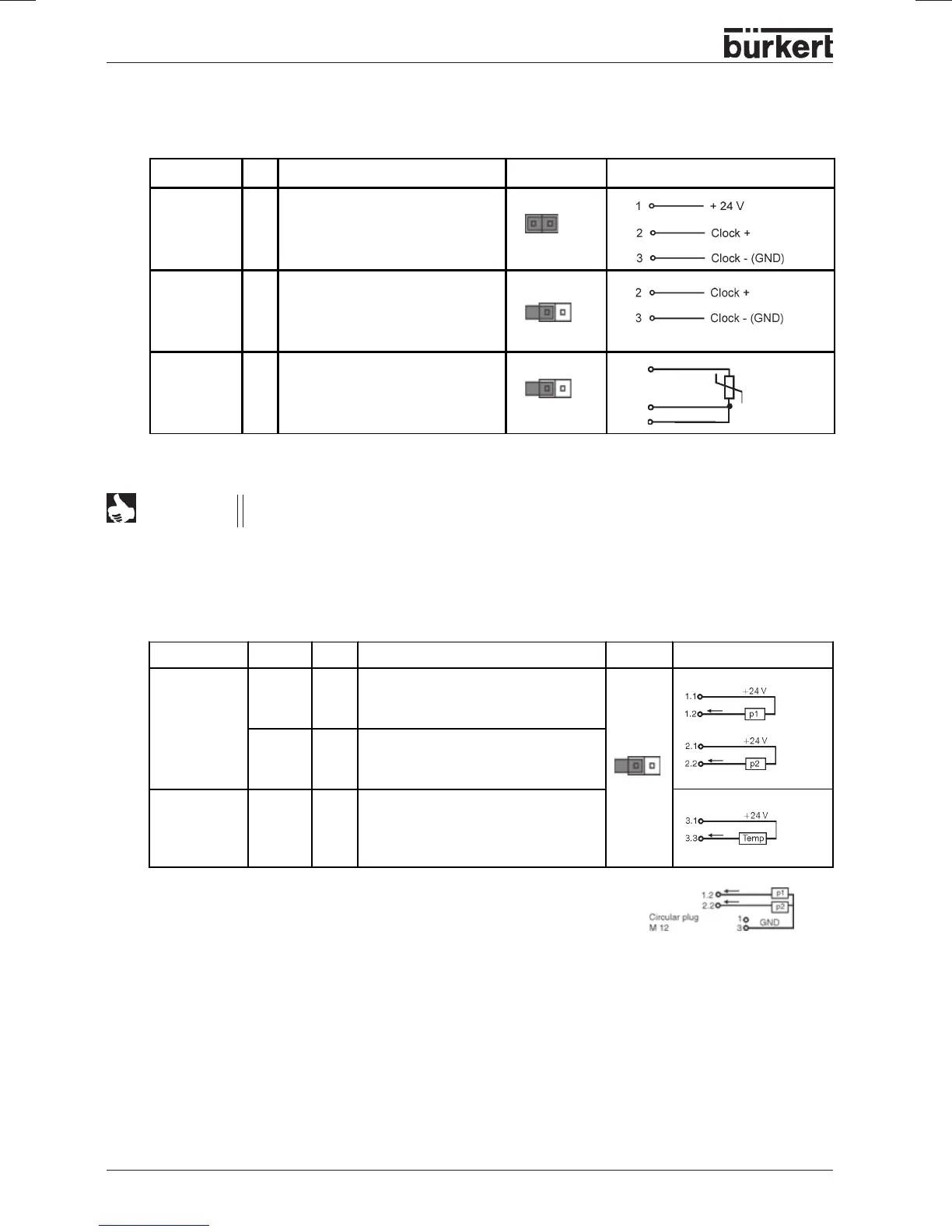

Input type * Pin Assignment Jumper external circuit

Frequency

internally

supplied

1

2

3

4

+ 24 V supply sensor

clock input +

not assigned

clock input - / GND

Frequency

externally

supplied

1

2

3

4

not assigned

clock input +

not assigned

clock input -

Pt-100 (see

Note)

1

2

3

4

not assigned

process actual 1 (current supply)

process actual 2 (GND)

process actual 3 (compensation)

*

adjustable via software

Process value (circular plug M8, continuation)

For line compensation reasons, connect sensor Pt-100 via three conductors. PIN3 and 4

must be bridged at the sensor.

NOTE

Termination connection for DeviceNet systems

On installing a DeviceNet system, it is important to have the correct termination circuit for the data lines.

The circuit avoids the occurrence of faults through signal reflections on the data lines. For this purpose

the main line is to be terminated at both ends with resistors of respectively 120 Ω and 1 / 4 W power

loss.

Pt100

2

3

4

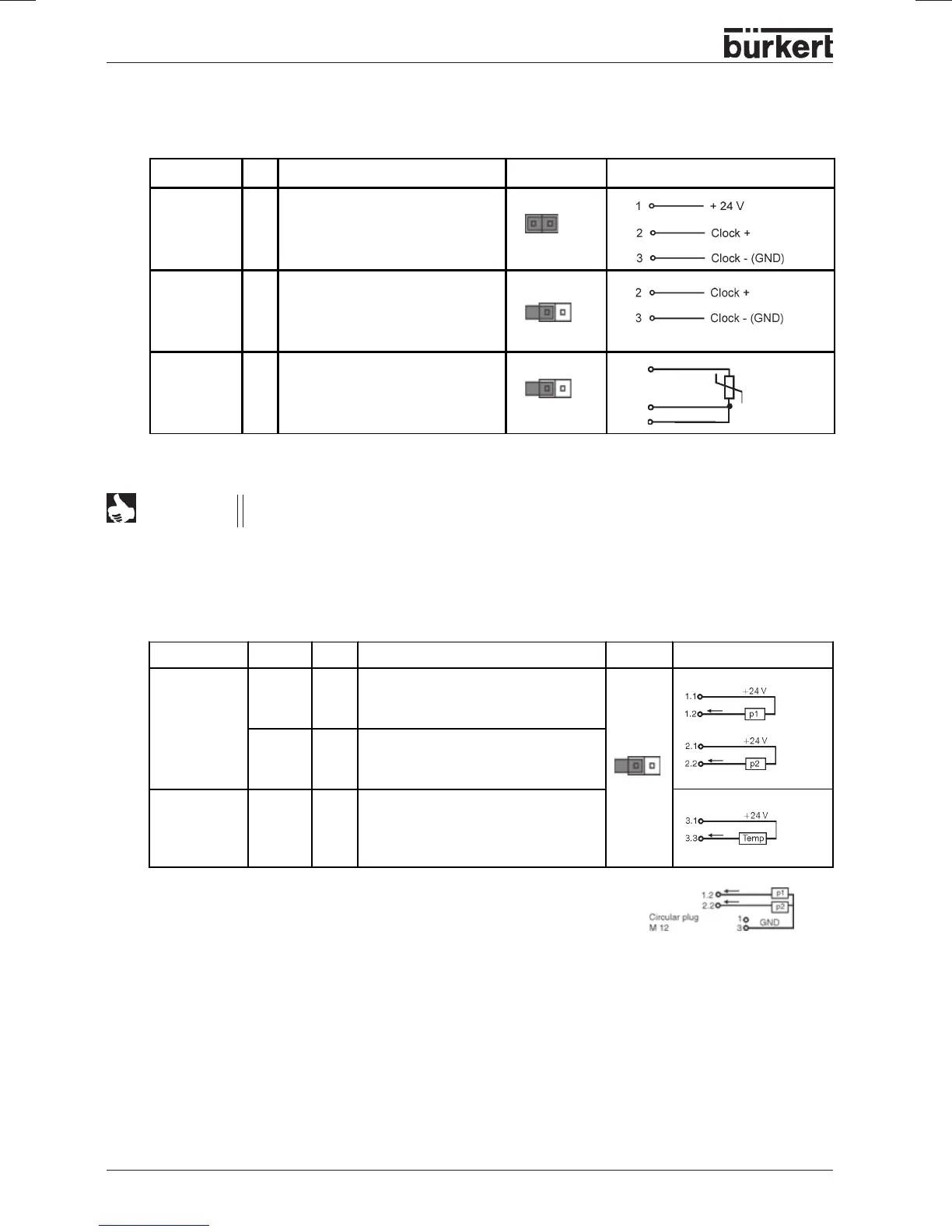

Actual process value for the fluid flow controller option (2 M8 round

plugs), or optionally: with temperature sensor input (3 M8 round

plugs)

* With external supply of the sensors the mass of the standard

signal must be connected with the mass of supply voltage.

Input type Plug Pin Assignment Jumper external circuit

internally

supplied

transmitter*

11

2

3 + 4

+ 24 V - transmitter supply p1

4 ... 20 mA - transmitter output p1

not assigned

21

2

3 + 4

+ 24 V - transmitter supply p2

4 ... 20 mA - transmitter output p2

not assigned

option:

temperature

transmitter*

31

3

2 + 4

+ 24 V - transmitter supply

4 ... 20 mA - output

transmitter temperature

not assigned

Loading...

Loading...