154 - 8630

MAINTENANCE AND ERROR CORRECTION ON THE PROCESS CONTROLLER

Error messages on the LC display

When operated according to these Operating Instructions, the TOP Control Continuous is

maintenance free.

Error messages and malfunctions

Maintenance

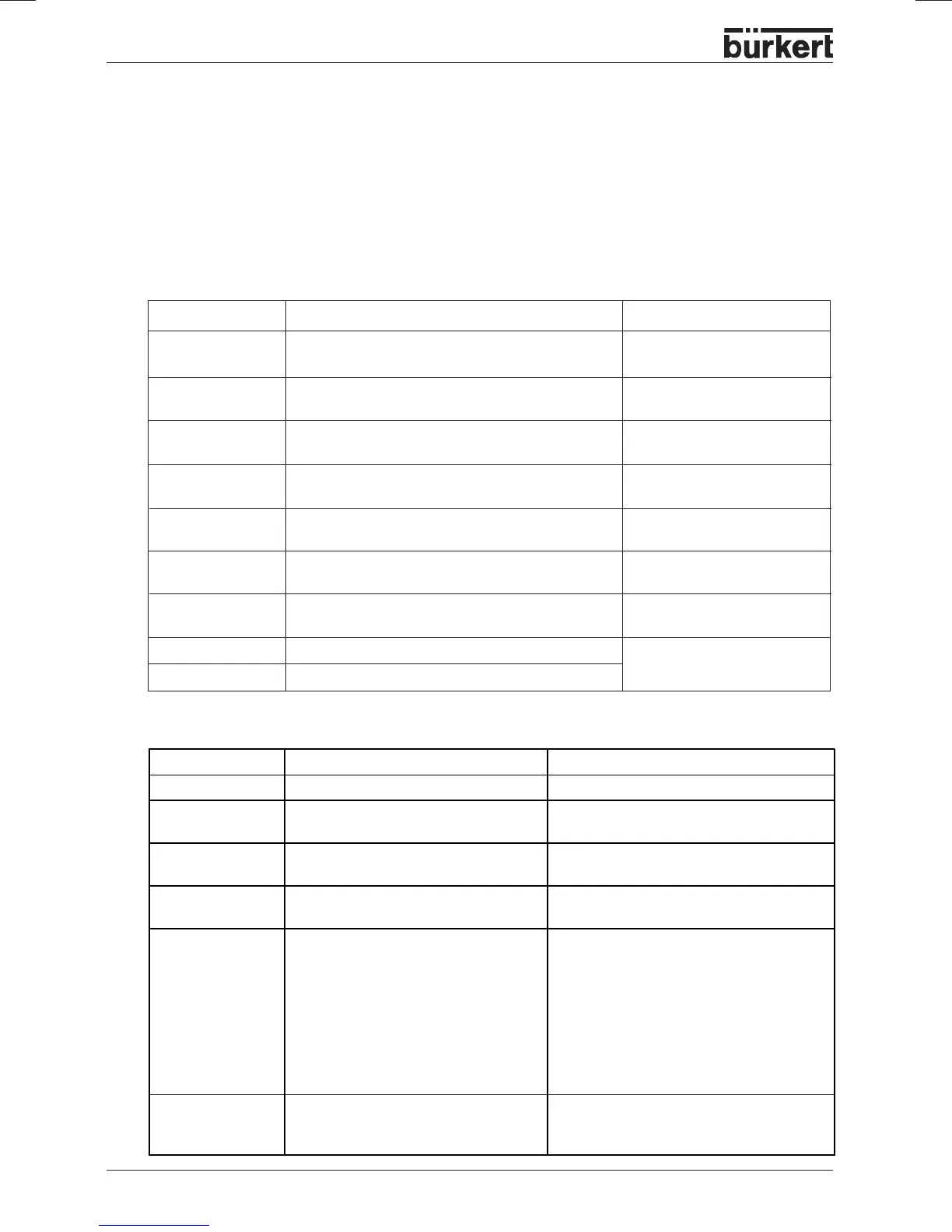

Error messages on execution of the function

X.TUNE

General error messages

Display Causes of error Remedy

X.ERR 1 No compressed air connected Connect compressed air

X.ERR 2 Compressed air failure during

AUTOTUNE

Check compressed air supply

X.ERR 3 Actuator or positioning system leaky

on exhaust side

None, device faulty

X.ERR 4 Actuator system leaky on pressurized

side

None, device faulty

X.ERR 6 The end positions for POS-MIN and

POS-MAX are too near to each other

Check whether the allocation of the end

positions to POS-MIN and POS-MAX via

the function TUNE-POS is correct.

If incorrect:

Execution TUNE-POS again.

If correct:

TUNE-POS with this arrangement of the

end positions is not possible since they

are too close together.

X.ERR 7 False allocation of POS-MIN and POS-

MAX

To determine POS-MIN and POS-MAX,

move the actuator in each case in the

direction shown on the display.

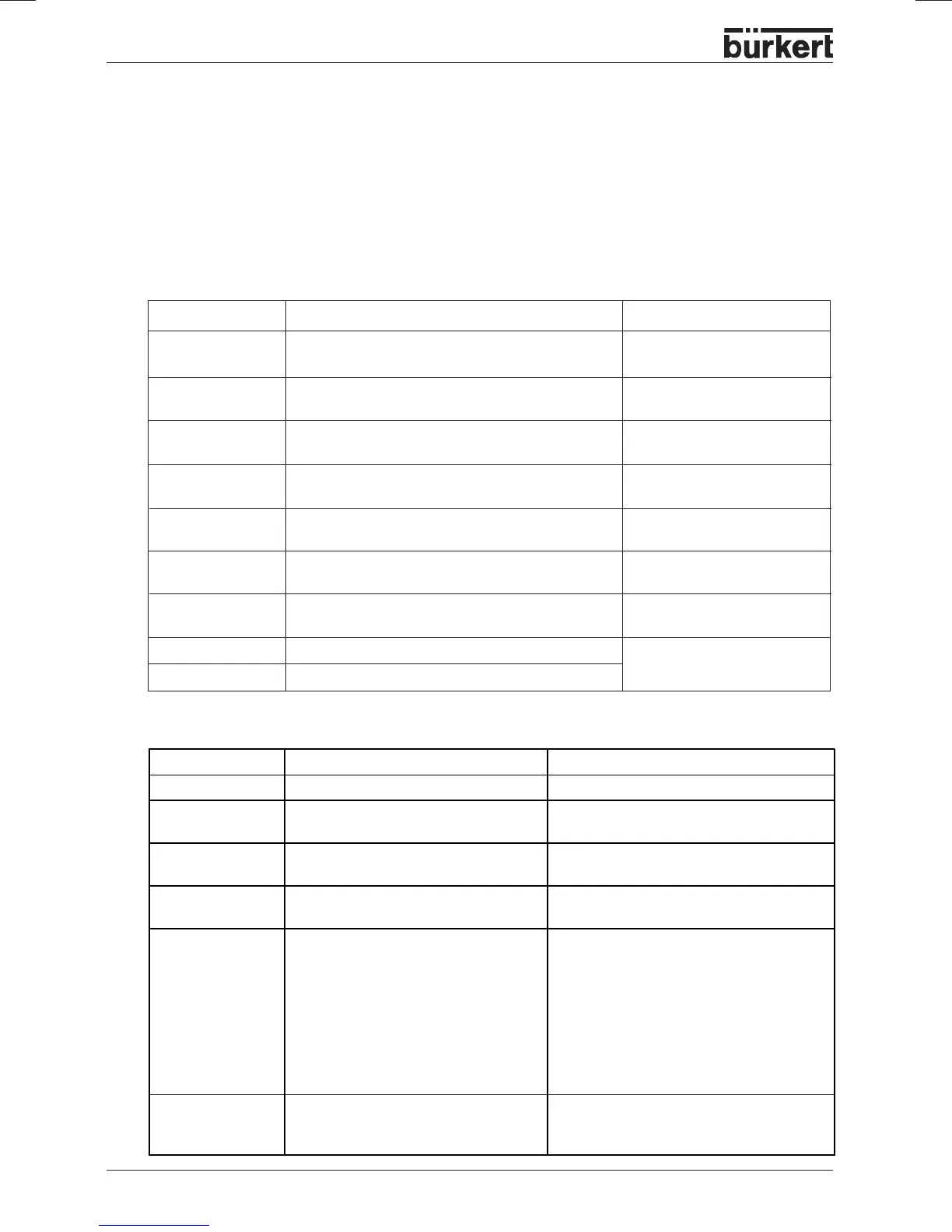

Display Causes of error Remedy

CMD FAUL

signal error check signal

set-value, positioner

SP FAULT

signal error check signal

set-value, process controller

PV FAULT

signal error check signal

actual value, process controller

PT FAULT

signal error check signal

actual value, Pt-100

P1 FAULT

signal error check signal

actual value, P1 fluid flow controller

P2 FAULT

signal error check signal

actual value, P2 fluid flow controller

TMP FAUL

signal error check signal

actual value, temperature, fluid flow controller

EE FAULT

EEPROM faulty none, device faulty

MFI FAUL

Fieldbus board faulty

Loading...

Loading...