8630 - 155

MAINTENANCE AND ERROR CORRECTION ON THE PROCESS CONTROLLER

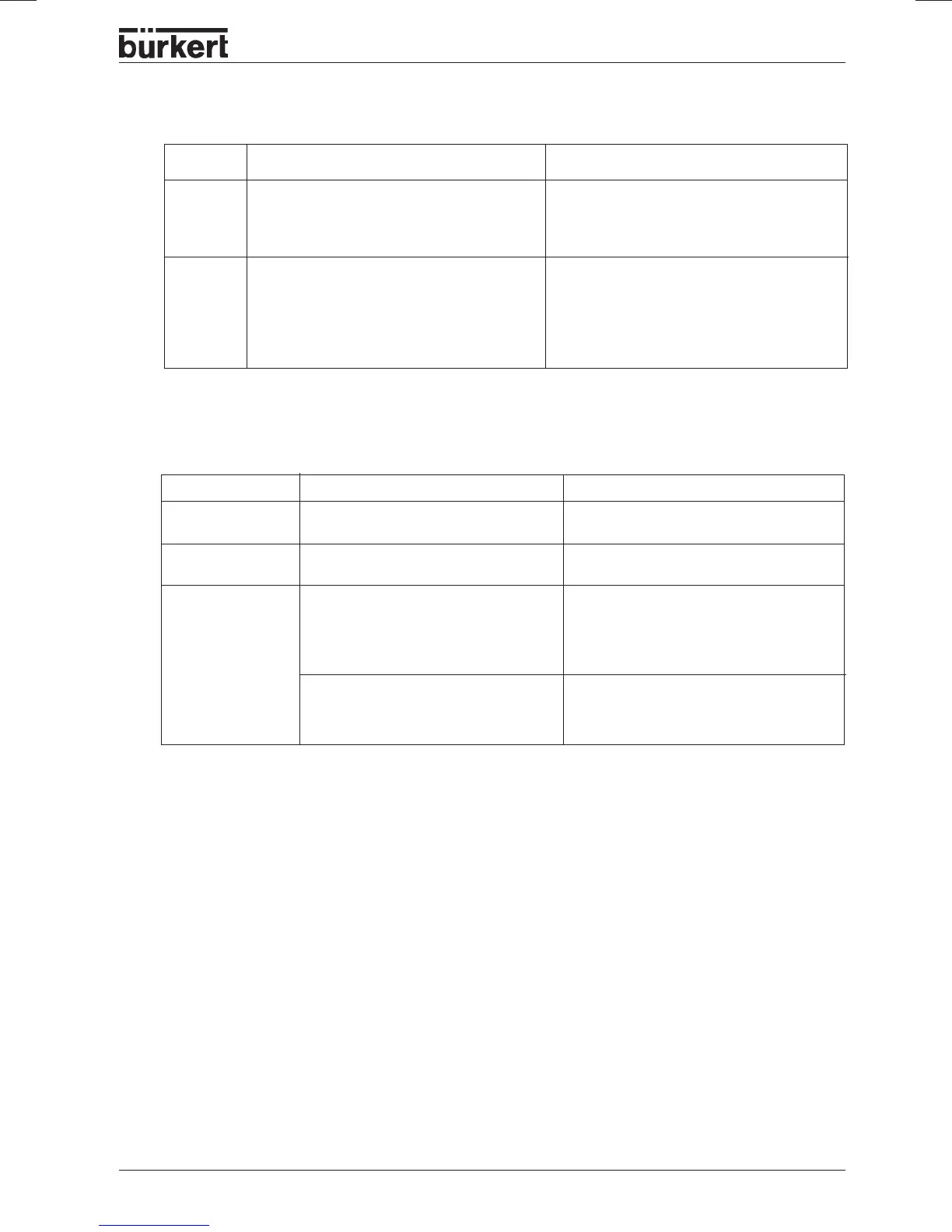

Error messages on execution of the function

P.Q'LIN

Display Causes of error Remedy

Q.ERR 1

No compressed air connected Connect compressed air

No change in process value Check process, switch on pump or open

shut-off valve if necessary

Q.ERR 2

Current fixed point of the valve stroke

was not reached because

•

Pressure supply failre

•

Check pressure supply

during

P.Q’LIN

•

No

AUTOTUNE

was executed

•

execute

AUTOTUNE

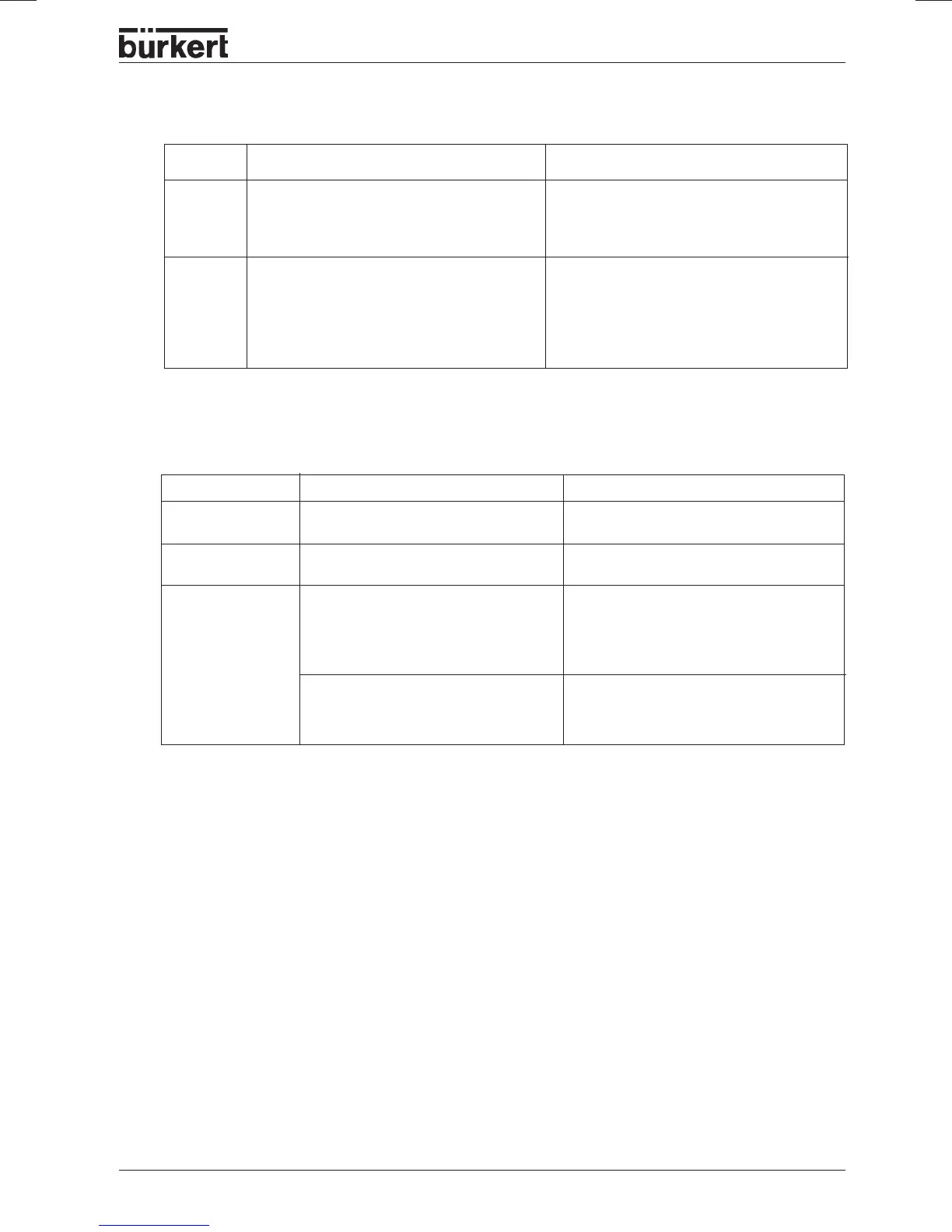

Display Cause of error Remedy

L.ERR 1

No admission pressure at the Switch on compressor before start of

controller unit (> 50 mbar). leakage measurement.

L.ERR 2

Control does not fully close. Execute AUTOTUNE.

L.ERR 3

No leakage detectable: The leakage characteristic must be

the difference between admission deactivated since the precision of air

pressure and conveying pressure is flow control cannot be raised.

so low, even at slight valve opening,

that no air leak can be measured.

Whilst the valve is open the delivery Make sure that the conveying pipe is

pressure is not increased, which closed and the blocking air is open.

means that no restart points for the

characteristic can be recorded.

Error message on execution of the function LEAK MEAS

Loading...

Loading...