18

ENG

UltraCella +0300083EN - rel. 1.5 - 07.02.2015

2.9 Installation

Proceed as follows for installation, making reference to the wiring

diagrams in the previous paragraphs:

1. Connect the supply and probes: the probes can be remote-controlled

up to a maximum distance of 10 metres from the controller as long as

cables with minimum section of 1 mm

2

are used.

2. Program the control: as indicated in chapter “Commissioning” and

“User interface”;

3. Connect the actuators: the actuators should only be connected after

having programmed the controller. It is recommended to carefully

evaluate the maximum capacities of the relays indicated in table

“Technical specifi cations”.

4. Connection to the serial network (if present): all controls are fi tted with a

serial connector for connection to the supervisory network.

Warnings: avoid installing UltraCella control system in environments with

the following characteristics:

• relative humidity over 90% non-condensing;

• strong vibrations or knocks;

• exposure to continuous jets of water;

• exposure to aggressive and polluting atmospheric agents (e.g.: sulphur

and ammonia gases, saline mist, smoke) to avoid corrosion and/or

oxidation;

• high magnetic and/or radio frequency interference (e.g. near

transmitting antennas);

• exposure of the control system to direct sunlight and atmospheric

agents in general.

The following recommendations must be respected when connecting

the controllers:

Warnings:

• incorrect connection of the power supply may seriously damage the

control system;

• use cable ends that are suitable for the terminals. Loosen every screw

and fi t the cable end, next tighten the screws and gently pull the cables

to check their tightness. If using an automatic screwdriver, adjust the

torque to a value less than 0.5 N · m;

• separate as much as possible (by at least 3 cm) the probe signal and

digital input cables from inductive loads and power cables, to avoid

any electromagnetic disturbance. Never lay power cables and probe

cables in the same cable conduits (including those for the electrical

panels). Do not install the probe cables in the immediate vicinity of

power devices (contactors, circuit breakers or other). Reduce the

length of the sensor cables as much as possible, and avoid spirals

around power devices;

• only use IP67 guaranteed probes as end defrost probes; place the

probes with the vertical bulb upwards, so as to facilitate drainage of

any condensate. Remember that the thermistor temperature probes

(NTC) have no polarity, so the order of connection of terminals is not

important.

Caution: in order to ensure the safety of the unit in the event of

serious alarms, all the electromechanical safety devices required

to guarantee correct operation must be fi tted on the unit.

HACCP - CAUTION

When the temperature measurement is relevant for Food Safety (see

HACCP), will be used only temperature probes suggested by Carel. The

standards in force may require the compilation and preservation of

appropriate documentation, as well as periodic checks on instrumentation

and sensors. If in doubt, consult the person in charge of food safety or the

manager of the plant.

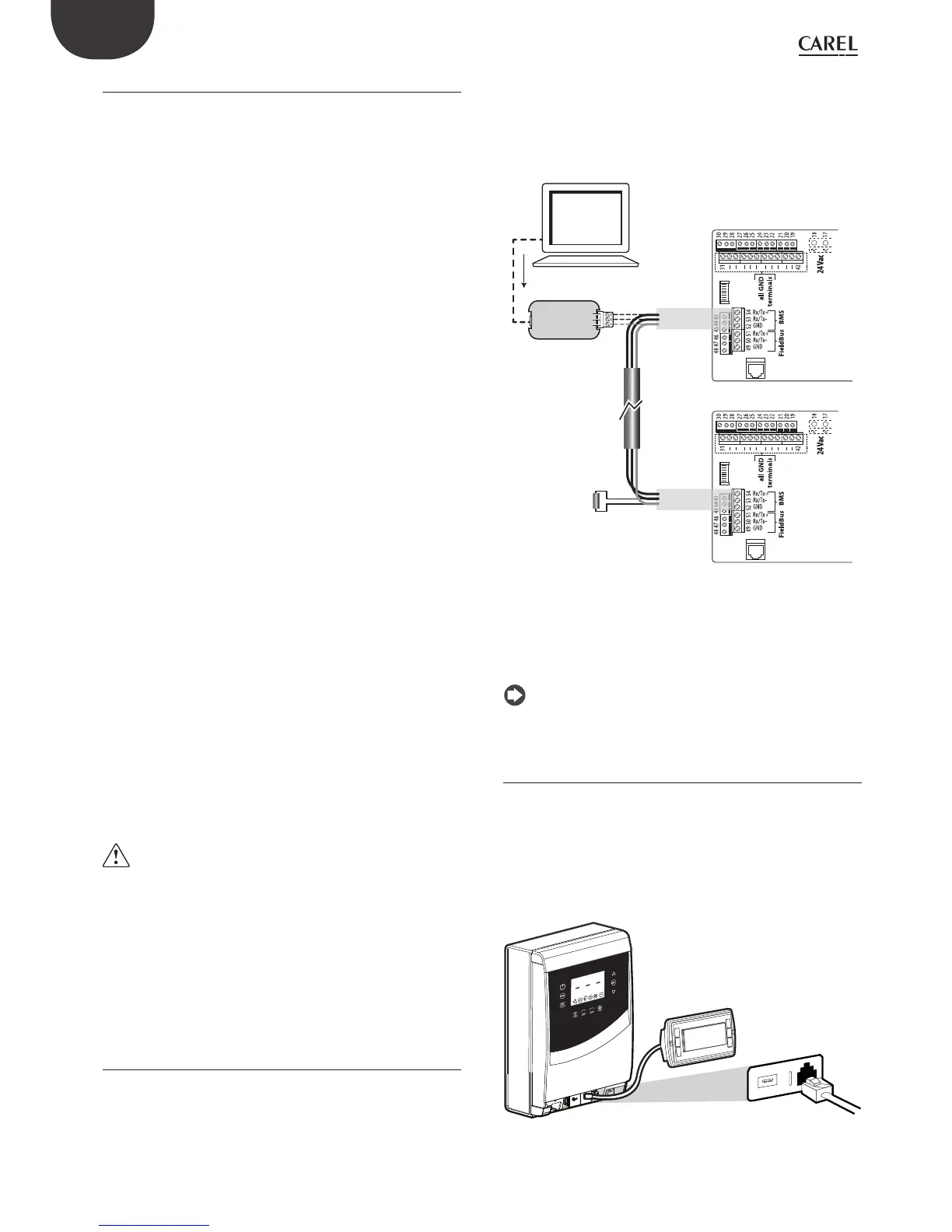

2.10 Connection in supervisoring network

Warnings:

• properly fi x the converter to avoid disconnections;

• perform the wiring without power supply;

• keep the cables of the converter CVSTDUMOR0 separate from power

cables (supply and relay outputs).

The RS485 converter allows you to connect to the UltraCella control

network to the monitoring network for complete control and monitoring

of controls connected. The system provides a maximum of 207 units with

a maximum length of 1000 m. For the connection it is requested the

accessory standard (RS485-USB converter cod. CAREL CVSTDUMOR0) and

a terminating resistor of 120 Ω to be placed on the terminals connected

to the last control. Connect RS485 converter to the controls as shown in

the fi gure. For assigning the serial address see the parameter H0. See the

instruction sheet of the converter for further information.

UltraCella 1

GND

USB-485

Converter

CVSTDUMOR0

120 Ω

T+

T -

GND

T+

T -

USB

UltraCella ...n

to BMS

port

GND

T+

T -

to BMS

port

Fig. 2.s

UltraCella can be connected to both PlantVisor and PlantWatch via BMS

port (RS485 Carel protocol).

Starting from 1.5 release software, both CAREL and Modbus protocols are

available from BMS port, selectable by H7 parameter.

- H7 = 0 CAREL protocol

- H7 = 1 Modbus protocol

Note: To make the change active, switch on and switch off the unit.

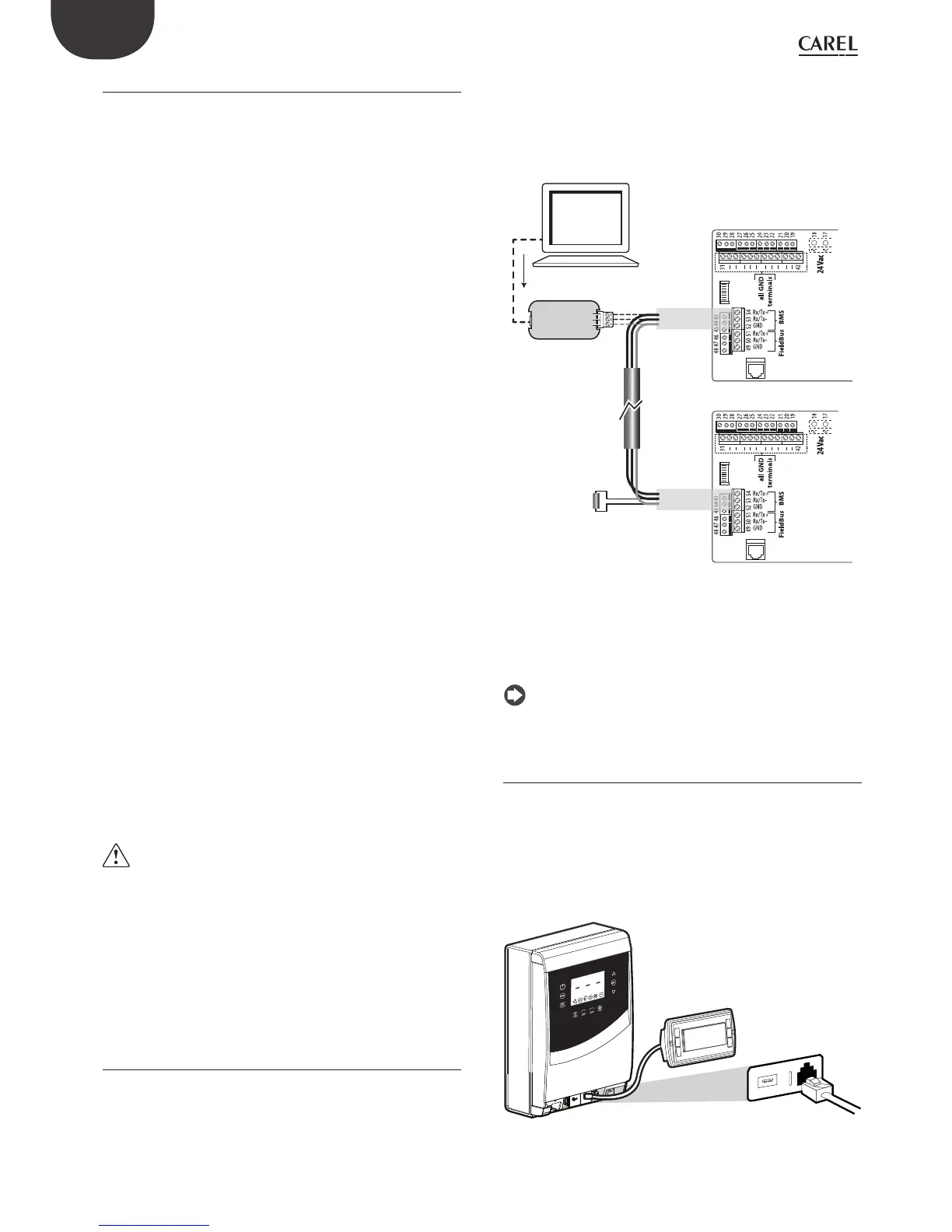

2.11 UltraCella Service terminal

The UltraCella Service Terminal has to be connected via a dedicated

connector, that can be accessed after removing the lower frame

Using the “UltraCella Service Terminal” you can:

• during the fi rst commissioning: insert the fi rst confi guration parameters

following the guided procedure (wizard);

• during normal operation:

1. display the active loads and the main variables: temperature, humidity;

2. perform the control programming, facilitated by contextual help.

1

2

1

2

Fig. 2.t

Loading...

Loading...