47

ENG

UltraCella +0300083EN - rel. 1.5 - 07.02.2015

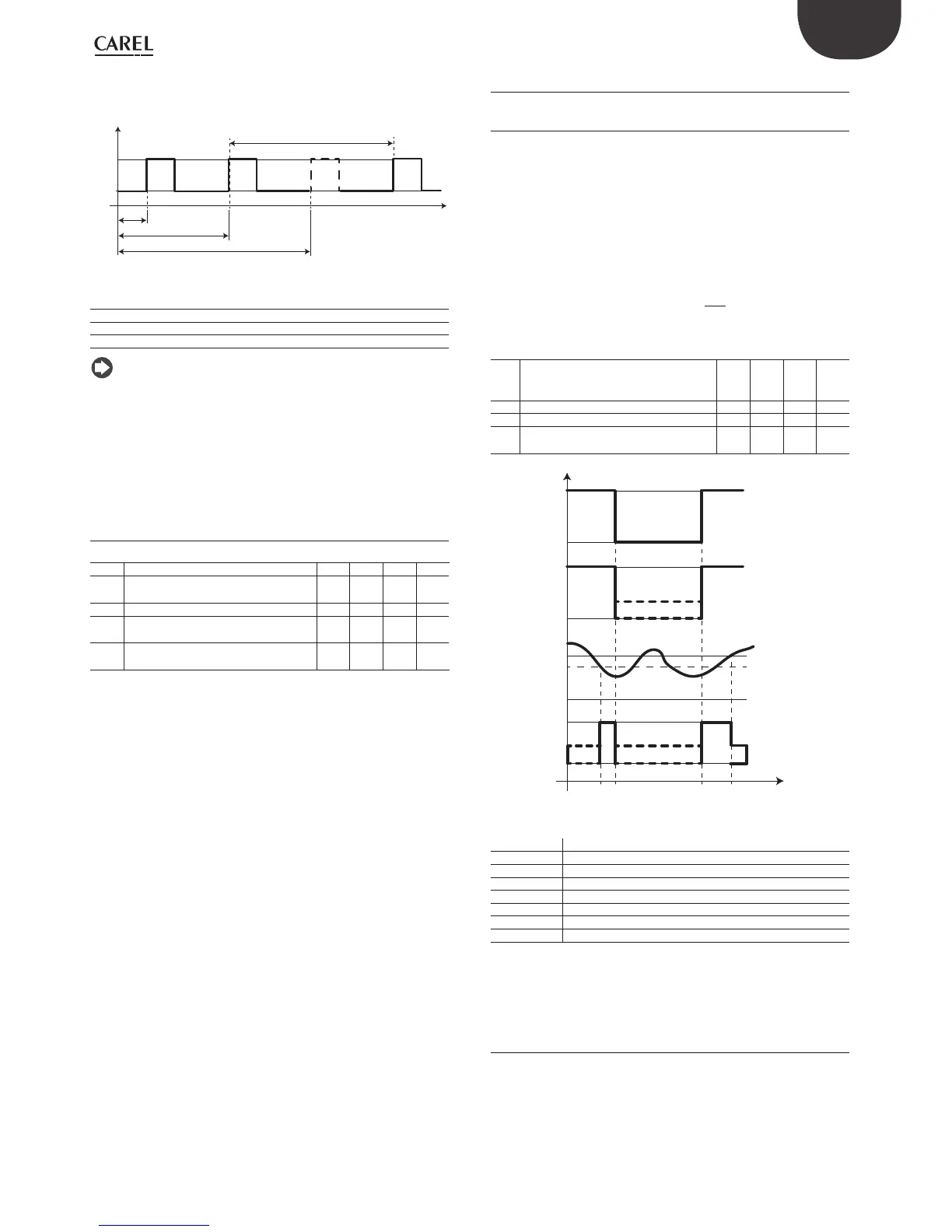

Example: in case of failure for example at RTC the scheduled defrost by

td3 (= dd3, hh3, nn3) is not made, after the safety time dI starts a new

defrost.

DEF

t

OFF

ON

dl

dd3

dd2

dd1

Fig. 6.m

Key

dI Maximum interval of time between consecutive defrosts

dd1…dd3 Scheduled defrosts

DEF Defrost

t Time

Note:

• if the interval dI expires when the controller is OFF, when it is started

again a defrost is performed;

• to ensure regular defrosts, the interval between defrosts must be

greater than the maximum defrost duration, plus the dripping time

and post-dripping time;

• if setting dl=0 the defrost is performed only if activated from keyboard

or by setting the scheduled defrosts (ddi).

6.8.2 Other defrost parameters

Par. Description Def Min Max U.M.

d3 Defrost activation delay 0 0 250 min

d4 Defrost at start-up

0/1=No/Yes

001-

d5 Defrost delay at start-up 0 0 250 min

d8 High temperature alarm delay after

defrost (and door open)

1 0 250 hour

dpr Defrost priority over continuos cycle

0/1=No/Yes

001-

• d3 determines the time that must elapse, when the defrost is activated,

between the stopping of the compressor (electric heater defrost) or

the starting of the compressor (hot gas defrost), and the activation of

the defrost relays on the main and auxiliary evaporators. In the hot gas

defrost, the delay d3 is useful for ensuring a suffi cient amount of hot

gas before activation of the hot gas valve;

• d4 determines whether to activate or not the defrost at the controller

start-up. The defrost at start-up request has priority over the activation

of the compressor and the continuous cycle. Force a defrost at

controller start-up may be useful in special situations.

Example: frequent power drops inside the plant. In case of lack of voltage

the tool resets the inner clock that calculates the period of time between

two defrosts, starting from zero. If, in an extreme case, the frequency of

the power failure were greater than the defrost frequency (e.g. a power

failure every 8 hours, against a defrost every 10 hours) the controller

would never perform a defrost. In a situation of this type, it is preferable

to activate defrost on start-up, above all if the defrost is controlled by

temperature (probe on the evaporator), therefore avoiding unnecessary

defrosts or at least reducing the running times. In the case of systems

with a large number of units, if selecting defrosts at start-up, after a power

failure all the units will start defrosting, thus causing a voltage overload.

This can cause power overload. To overcome this, the parameter d5 can

be used. It adds a delay before the defrost, and this delay must obviously

be diff erent for each unit.

• d5 represents the time that elapses between the start of the controller

and the start of the defrost at start-up;

• dd is used to force the stop of the compressor and the evaporator fan

after a defrost cycle in order to facilitate the evaporator dripping;

• d8 indicates the time of exclusion of the high temperature alarm

signalling from the end of a defrost;

• if dpr = 0, the defrost and the cycle have the same priority; if dpr = 1,

if the continuous cycle is in progress and a defrost request intervenes,

the continuous cycle ends and the defrost starts.

6.9 Evaporator Fans

6.9.1 Fixed speed fans

The status of the fans depends on the compressor status.

When the compressor is:

• on: the fan can also be on (F0=0) or activated based on the evaporator

temperature, virtual probe Sv, based on the formula:

if Sd ≤ (Sv - F1) -Frd --> FAN = ON

if Sd ≥ (Sv - F1) --> FAN = OFF

• off : the fan is controlled by a PWM that has duty cycle with a fi xed

period of 60 minutes.

duty_cycle =

60

F2

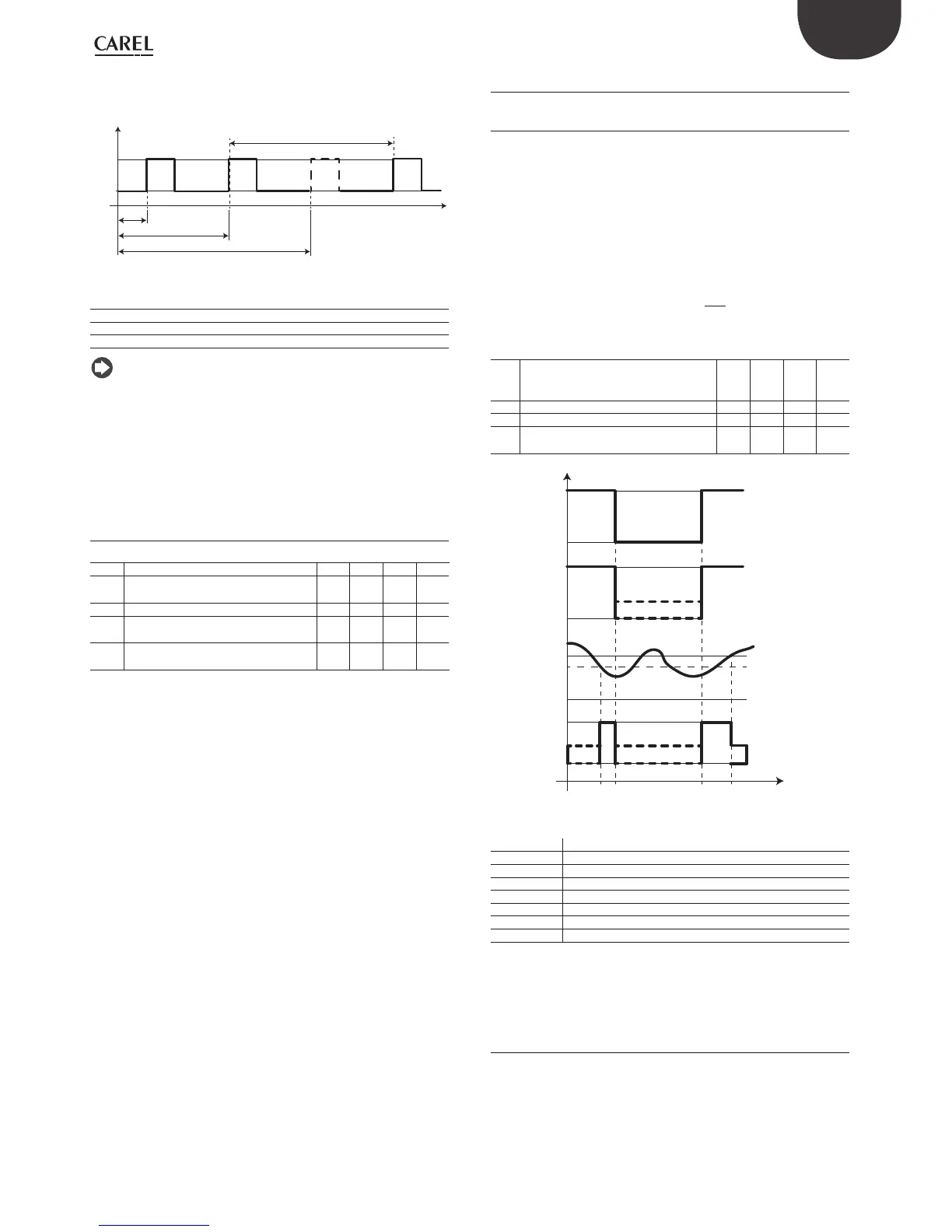

Par. Description Def Min Max U.M.

F0 Evaporator fan management

0 = always on with compressor on

1= activation depends on Sd, Sv

002-

F1 Fan activation temperature 5 -50 200 °C/°F

F2 Fan activation time with CMP off 30 0 60 min

HO1 Output Y1 confi guration

0 = not active

002-

Evap. fan

Evap. fan

CMP

Sd

t

F0=0

F0=1

(*)= PWM mod.

PWM mod.

OFF

ON

ON

ON

Sv-F1

(Sv-F1)-Frd

(*) (*) (*)

Fig. 6.n

Key

CMP Compressor

PWM mod. PWM modulation

F1 Fan activation threshold

Frd Fan activation diff erential

Evap.fan Evaporator fan

t Time

Sv Virtual probe

Sd Defrost probe

The fan can be stopped:

• when the compressor is off (parameter F2);

• during defrost (parameter F3).

6.9.2 Variable speed fans

The installation of variable speed fans may be useful to optimise energy

consumption. In this case, the fans are powered by the mains, while the

control signal is provided by UltraCella by analogue output Y1 0…10 Vdc.

The maximum and minimum fan speed can be set using F6 and F7

parameters (in percentage respect range 0…10V). If using the fan speed

controller, F5 represents the temperature below which the fans are

activated, with a fi x hysteresis of 1°C.

Loading...

Loading...