Paragraphs 4-5

CASE/iNTERNATiONAL

rearward from axle. Remove cap screws (1), caps (2)

and gaskets (3). Remove nut and lockwasher from

lock pin

(15).

Drive lock pin forward out of axle main

member Using a hammer and punch, drive kingpin

(12) out of axle and spindle. Remove spindle, thrust

bearing (14) and shim (13) if so equipped.

Inspect kingpin bushings (4) and renew if neces-

sary. Bushings should be installed until inner ends

of bushings are 0.016-0.031 inch (0.4-0.8 mm) below

the inside surfaces of spindle bores. Lubrication

grooves in bushings must align with lubrication

fittings.

Install a new thrust bearing (14), with TOP mark

up,

on bottom inside edge of spindle. Install spindle

over end of axle main member with thrust bearing

under axle. Use a jack to hold spindle and bearing

tight against bottom of axle. Using a feeler gage,

measure gap between upper edge of axle and the

spindle. If gap is more than 0.005 inch (0.127 mm),

install shims to reduce gap to less than 0.005 inch

(0.127 mm). Shims are available in thicknesses of

0.005 and 0.010 inch (0.127 and 0.254 mm).

Inspect kingpin (12) and renew as necessary. Install

kingpin with flat nearest to the top and in alignment

with hole for the lock pin

(15).

Install lock pin, lock-

washer and nut. Tighten nut securely. Install steer-

ing arm and tighten bolts (22) and nuts to a torque

of 160-180 ft.-lbs. (217-244 N-m). Install lubrication

fitting in steering arm.

Check oil seal (1—Fig. 2) and install new seal, if

needed, then install hub and adjust bearings as out-

lined in paragraph 1.

AXLE MAiN MEMBER AND PiVOT PiN

All Modeis With Adjustabie Axies

4.

REMOVE AND REINSTALL. 1b remove axle

main member (13—Figs. 3, 4 and 5), first block rear

wheels securely and apply park

brake.

If

so

equipped,

remove front weights and weight bracket. Unbolt and

remove front cover. Support tractor with stands un-

der side rails or oil pan, and remove front wheels.

Disconnect tie rod ends from left and right steering

arms (2 and 6). Unbolt and remove axle extensions

(4 and 5) with spindle assemblies. Identify and dis-

connect steering cylinder hoses at cylinder. Cap and

plug all openings. Remove the cylinder anchor clevis

pin. Straighten corners of lock plate (21) and remove

cap screws (22), lock plate (21) and cylinder retain-

ing bar (20). Hold cylinder upward and slide cylin-

der clevis from anchor on axle. Remove steering cyl-

inder. Remove center steering arm (19) and tie rods.

Place a floor jack under axle main member

(13).

Re-

move cap screws (16) and thread a slide hammer

puller into front end of pivot pin

(15).

Remove pivot

pin, then lower axle main member and remove from

under tractor.

Inspect axle pivot bushings

(14)

and renew if neces-

sary, aligning lubrication holes with lubrication fit-

tings.

Inspect cylinder pivot bushings (18) and steer-

ing arm pivot bushings (17) and renew as necessary.

Reinstall by reversing removal procedure, keeping

the following points in mind: Tighten cap screws (16)

and (22) to a torque of 80-90 ft.-lbs. (110-124 N-m).

Bend corners of lock plate (21) against flat of bolt

head (22). Tighten nuts on shoulder bolts (12) to a

torque of 246-272 ft.-lbs. (334-369 N-m). Tighten tie

rod end slotted nuts to a torque of 50 ft.-lbs. (68 N-m).

Aii Modeis With Nonadjustabie Cast Axle

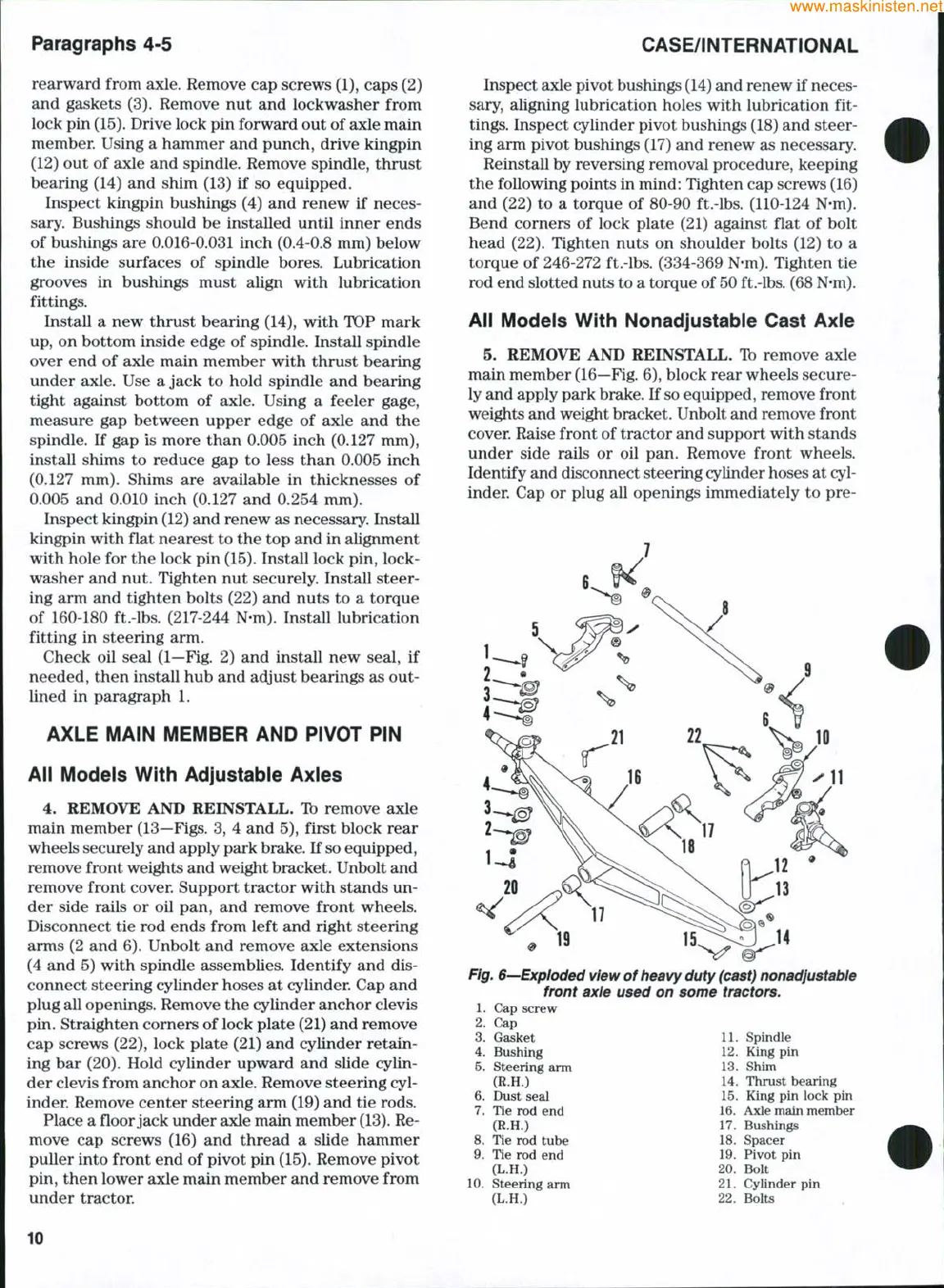

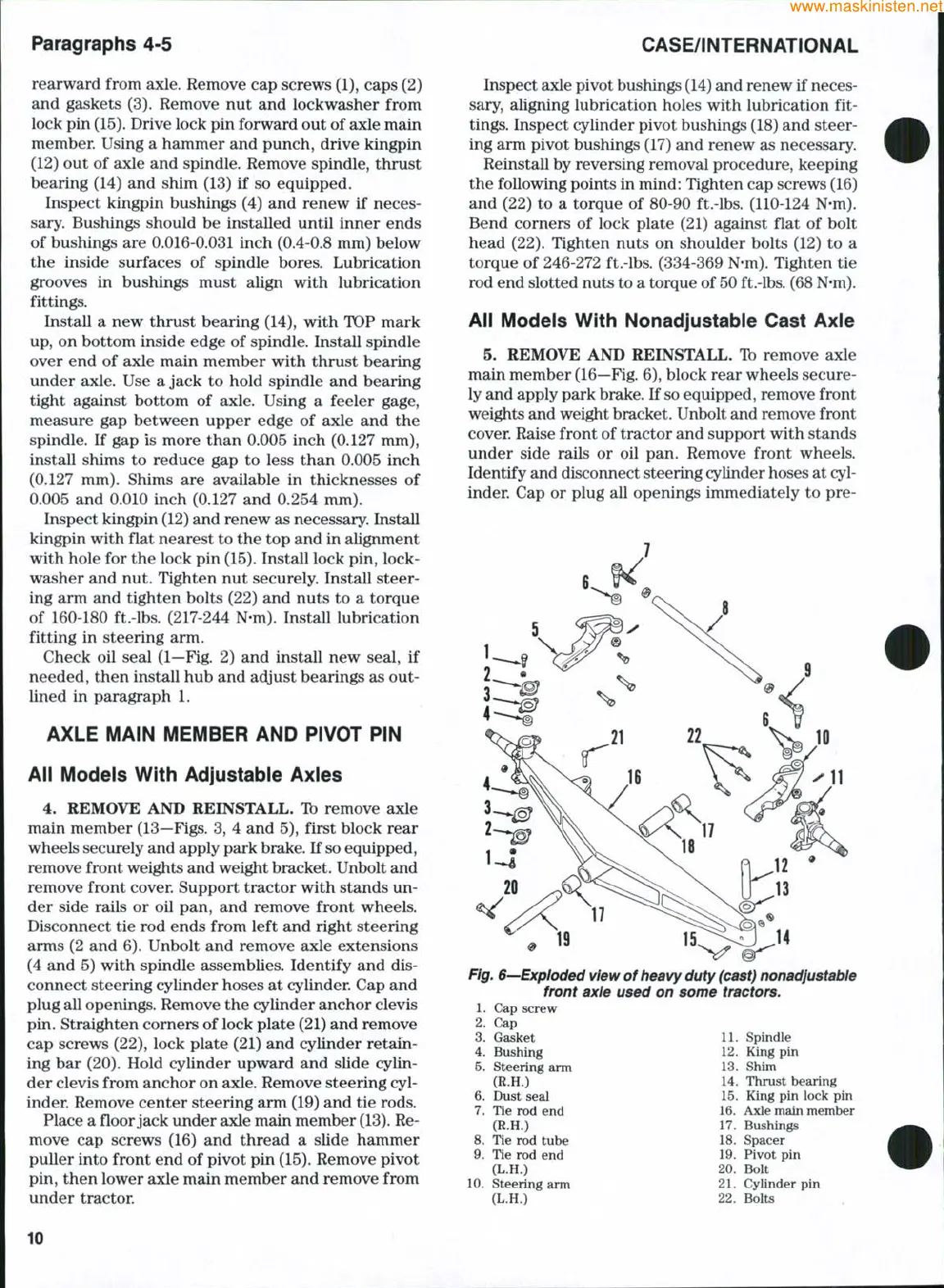

5. REMOVE AND REINSTALL. Ib remove axle

main member

(16—Fig.

6), block rear wheels secure-

ly and apply park

brake.

If

so

equipped, remove front

weights and weight bracket. Unbolt and remove front

cover. Raise front of tractor and support with stands

under side rails or oil pan. Remove front wheels.

Identify and disconnect steering cylinder hoses at cyl-

inder. Cap or plug all openings immediately to pre-

Fig.

6-—Exploded

view of heavy duty

(cast) nonadjustable

front axle used on some tractors.

1.

Cap screw

2.

Cap

Gasket 11. Spindle

3.

4.

Bushing

5.

Steering arm

(R.H.)

6. Dust seal

7.

Tie rod end

(R.H.)

8. Tie rod tube

9. Tie rod end

(L.H.)

Steering arm

(L.H.)

10

12.

King pin

13.

Shim

14.

Thrust bearing

15.

King pin lock pin

16.

Axle main member

17.

Bushings

18.

Spacer

19.

Pivot pin

20.

Bolt

21.

Cylinder pin

22.

Bolts

10

Loading...

Loading...