Paragraphs 138-139

CASE/INTERNATIONAL

to a torque of 80-90 ft.-lbs. (110.6-124.4 N-m). Adjust

control levers as outlined in paragraphs 131,132,133

and 134.

Models With Cab

138,

REMOVE AND REINSTALL.

Tb

remove the

hydraulic lift housing, first remove the cab as outlined

in paragraph 145. Disconnect lower end of adjusting

rod for raise rate lever, then disconnect lower adjust-

ing rods from draft and position control levers. Sep-

arate ac^usting rods from auxiliary valve control

levers, if so equipped. Disconnect pto linkage and lift

off the control levers box. Disconnect speed trans-

mission and range transmission shift linkage. Discon-

nect park brake linkage. Disconnect and remove in-

let and outlet pipes from raise rate valve. Cap or plug

all hydraulic openings immediately. Remove pto tube

and cross shaft. Disconnect and remove remote valve

pipes and remote couplers. Disconnect and remove

pipe from unloading and flow control valve. Discon-

nect and remove any other necessary hydraulic tubes.

Remove third link from sensing bracket and discon-

nect lift links from upper lift arms. Unbolt lift hous-

ing, attach a sling and hoist, then lift housing from

tractor.

Thoroughly clean mounting surfaces and apply a

1/8 inch (3 mm) bead of Loctite 515 on the center of

the mounting surface of transmission case. Install

three new Tbflon seals in grooves in face of transmis-

sion. Reinstall hydraulic housing over the two locat-

ing dowels. Tighten the 3/8 inch cap screws to a

torque of

33-37

ft.-lbs. (45.6-51.5

N-m)

and the 1/2 inch

cap screws to a torque of 80-90 ft.-lbs. (110.6-124.4

N-m).

Complete installation by reversing the removal

procedure. Adjust control levers as outlined in para-

graphs 131, 132, 133 and 134.

CYLINDER AND VALVE UNIT

All Models

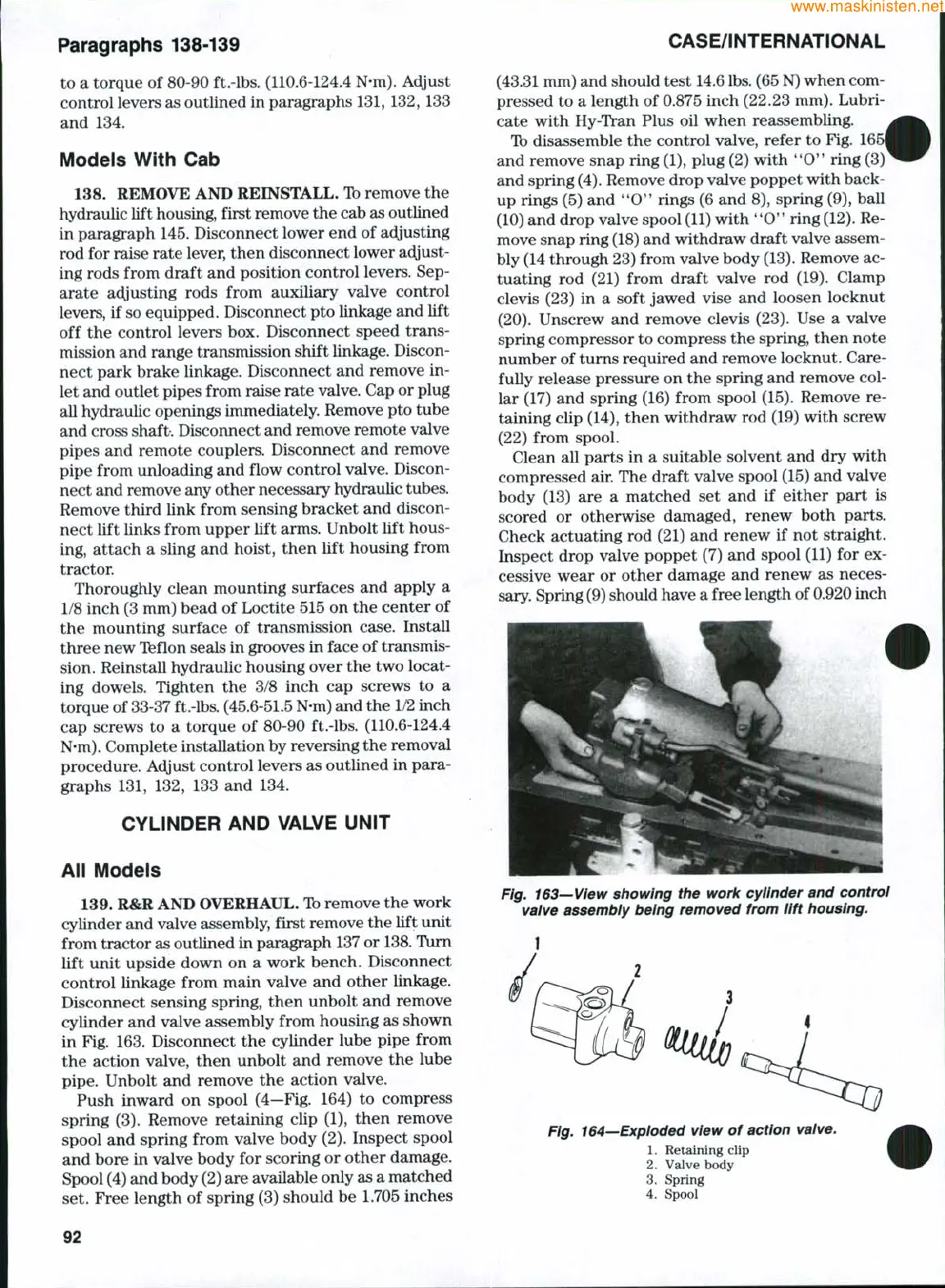

139.

R&R AND OVERHAUL.

Tb

remove the work

cylinder and valve assembly, first remove the lift unit

from tractor as outlined in paragraph

137

or

138.

Turn

lift unit upside down on a work bench. Disconnect

control linkage from main valve and other linkage.

Disconnect sensing spring, then unbolt and remove

cylinder and valve assembly from housing as shown

in Fig. 163. Disconnect the cylinder lube pipe from

the action valve, then unbolt and remove the lube

pipe.

Unbolt and remove the action valve.

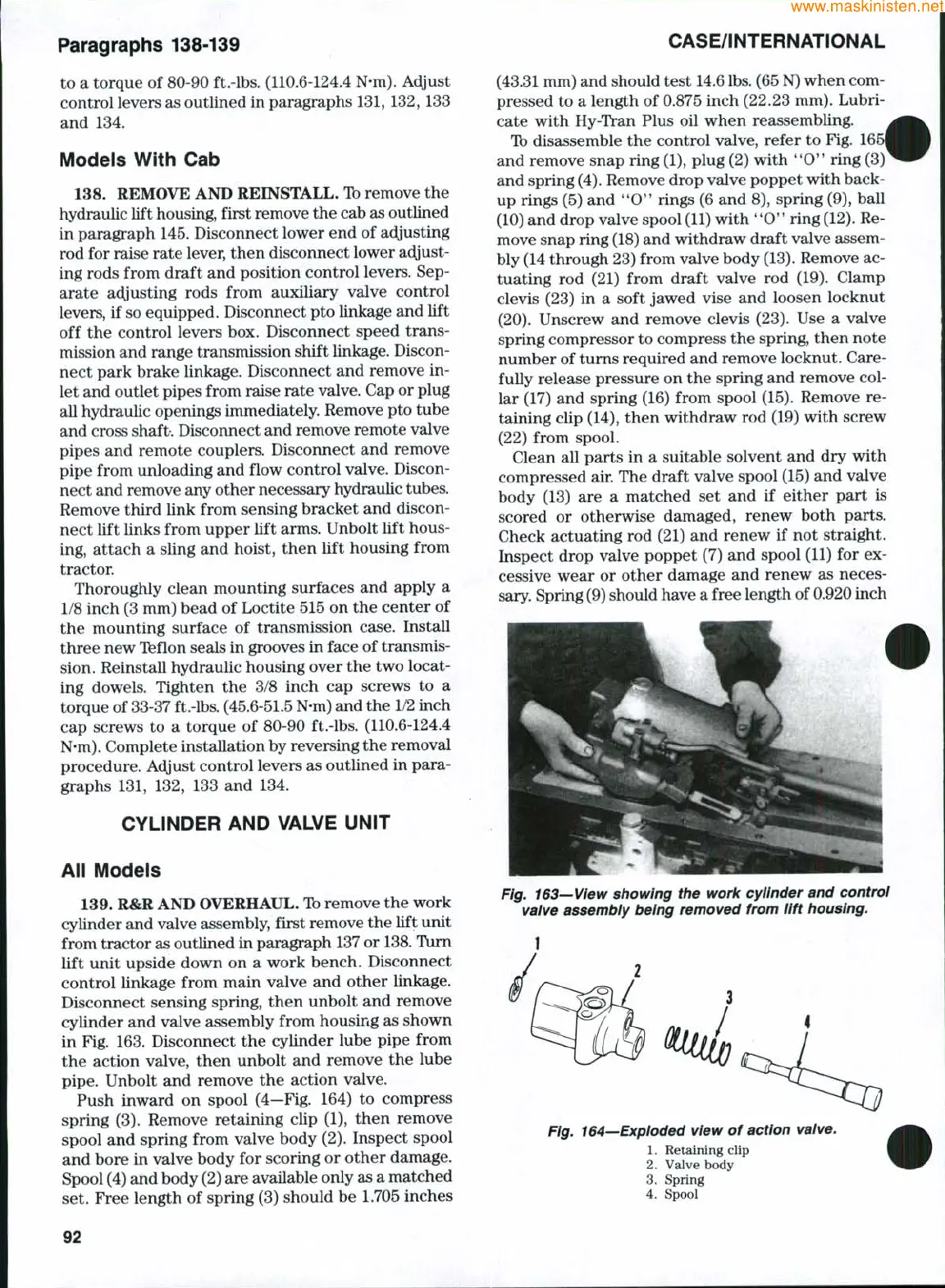

Push inward on spool (4—Fig. 164) to compress

spring (3). Remove retaining clip (1), then remove

spool and spring from valve body (2). Inspect spool

and bore in valve body for scoring or other damage.

Spool (4) and body (2) are available only as a matched

set. Free length of spring (3) should be 1.705 inches

(43.31 mm) and should test

14.6 lbs.

(65

N)

when com-

pressed to a length of 0.875 inch (22.23 mm). Lubri-

cate with Hy-Tran Plus oil when reassembling.

Tb disassemble the control valve, refer to Fig. 16

and remove snap ring (1), plug (2) with

**0**

ring (3)

and spring

(4).

Remove drop valve poppet with back-

up rings (5) and

**0*'

rings (6 and 8), spring (9), ball

(10) and drop valve spool

(11)

with

'*0**

ring

(12).

Re-

move snap ring

(18)

and withdraw draft valve assem-

bly (14 through 23) from valve body

(13).

Remove ac-

tuating rod (21) from draft valve rod (19). Clamp

clevis (23) in a soft jawed vise and loosen locknut

(20).

Unscrew and remove clevis (23). Use a valve

spring compressor to compress the spring, then note

number of turns required and remove locknut. Care-

fully release pressure on the spring and remove col-

lar (17) and spring (16) from spool (15). Remove re-

taining clip (14), then withdraw rod (19) with screw

(22) from spool.

Clean all parts in a suitable solvent and dry with

compressed air. The draft valve spool (15) and valve

body (13) are a matched set and if either part is

scored or otherwise damaged, renew both parts.

Check actuating rod (21) and renew if not straight.

Inspect drop valve poppet (7) and spool (11) for ex-

cessive wear or other damage and renew as neces-

sary. Spring

(9)

should have a free length of 0.920 inch

Fig. 163—View showing the work cylinder and control

valve assembly being removed from lift housing.

Fig. 164—Exploded view of action valve.

1.

Retaining clip

2.

Valve body

3.

Spring

4.

Spool

92

Loading...

Loading...