Chapter 2 Operating Principles

2-1. Operation of Each Mechanism

CL-S400DT 2-4

2-1. Operation of Each Mechanism

This printer is a direct thermal label & barcode printer comprised of the following mechanisms:

media feed, label/tag detection, print head up/down detection, head balance adjustment and media

thickness adjustment.

This section describes the operation of each of these mechanisms.

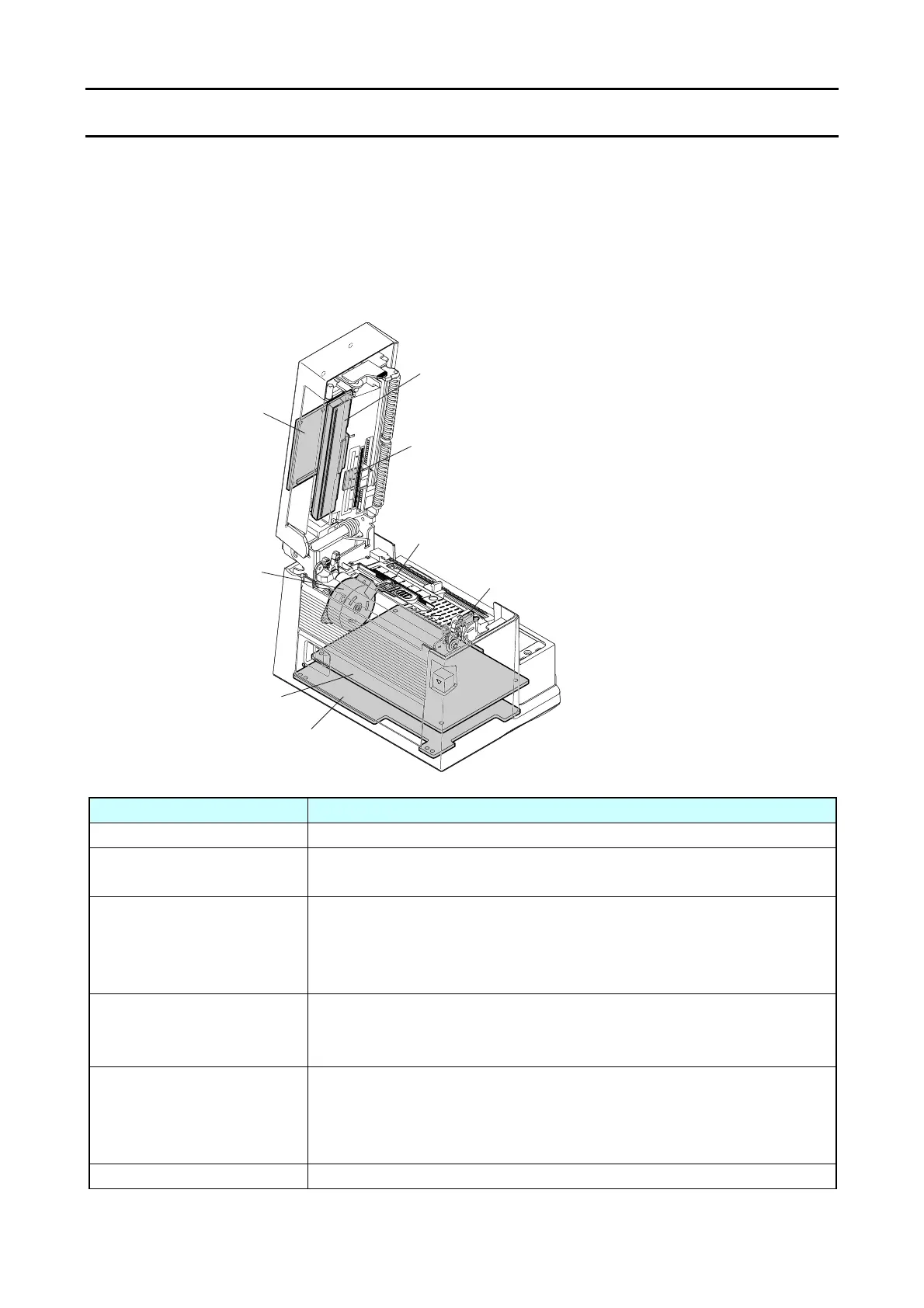

2-1-1. Locations of Main Electrical Parts

The following figure shows the locations of main electrical parts.

Part name Description

Unit, Motor This motor feeds media.

SA2 Head Up SW

(Head Up Sensor)

This sensor is a mechanical switch to detect the print head position;

up or down.

SA Adjust Sensor U

(Adjustable sensor

(Transparent sensor))

This sensor consists of a phototransistor and is used to detect a

label stuck on liner and a U-shaped notch on tag by the

combination of this sensor and the light emitter of the “SA Adjust

Sensor L”. The sensor also detects a media end.

SA Adjust Sensor L

(Adjustable sensor

(Reflective sensor))

This is a reflective type photointerrupter that detects a black mark

on the back of media and media end.

SA2 Head This is a thermal head consisting of a head driver and thermal

elements. Used to print on media by heating the thermal elements.

It incorporates two thermistors to detect the temperature of “SA2

Head”.

SA Main PCB Controls entire printer system.

100V

200V

0

1

2

3

4

5

Unit Motor

SA Head Up SW

SA Adjust Sensor L

SA Adjust Sensor U

SA2 Head

SA LCD PCB

SA Main PCB

SA Power Supply

Loading...

Loading...