TIC QUANTUM Hydraulics

10/04 11-37

Attention: In the two following systems, the pressure relief valve of the forage

wagon must be set higher than the pressure relief valve of the tractor:

3.0.3 Constant-pressure

pump

Tractors with constant-pressure pump = closed hydraulic system

(e.g. John Deere 50/55 series):

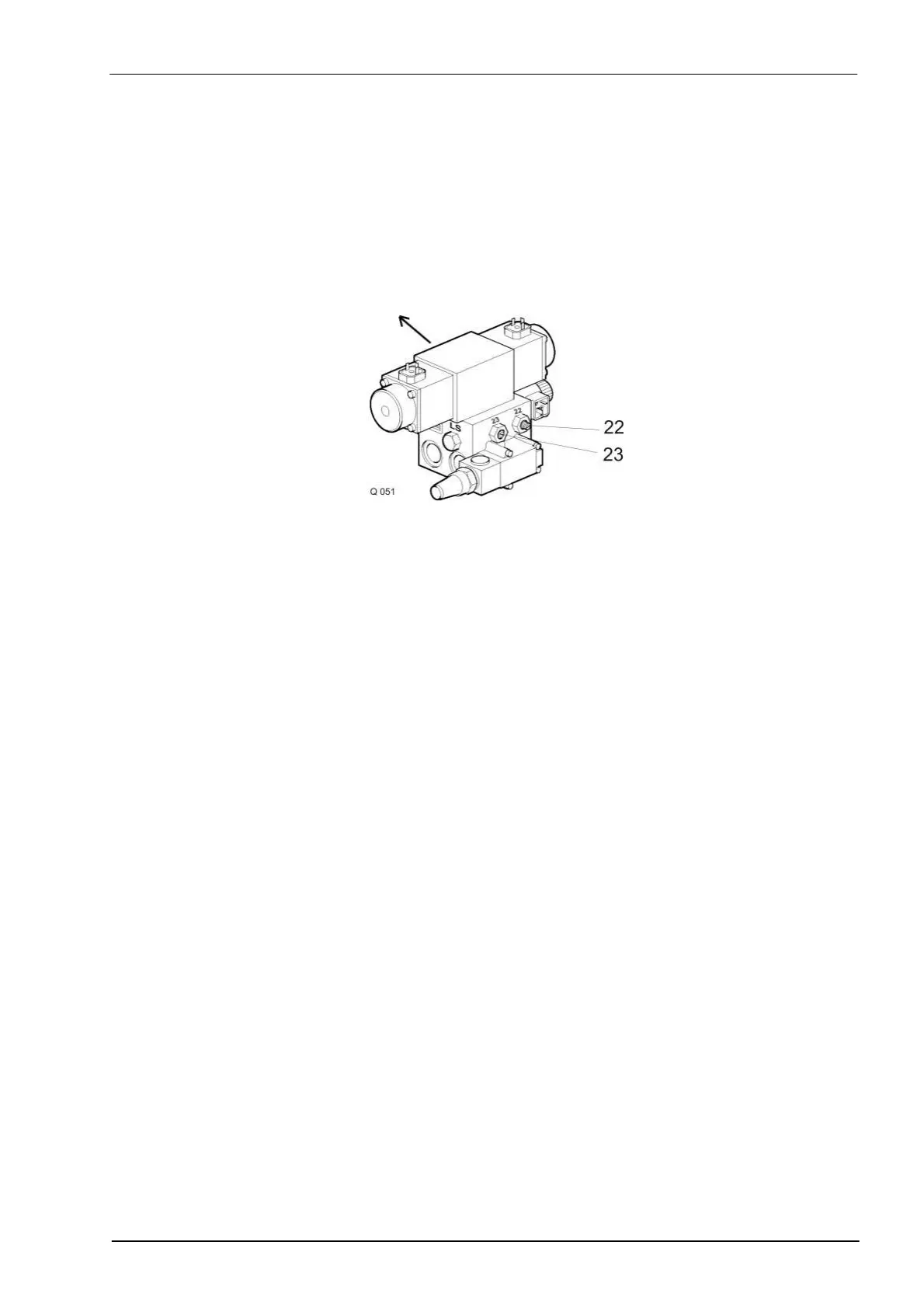

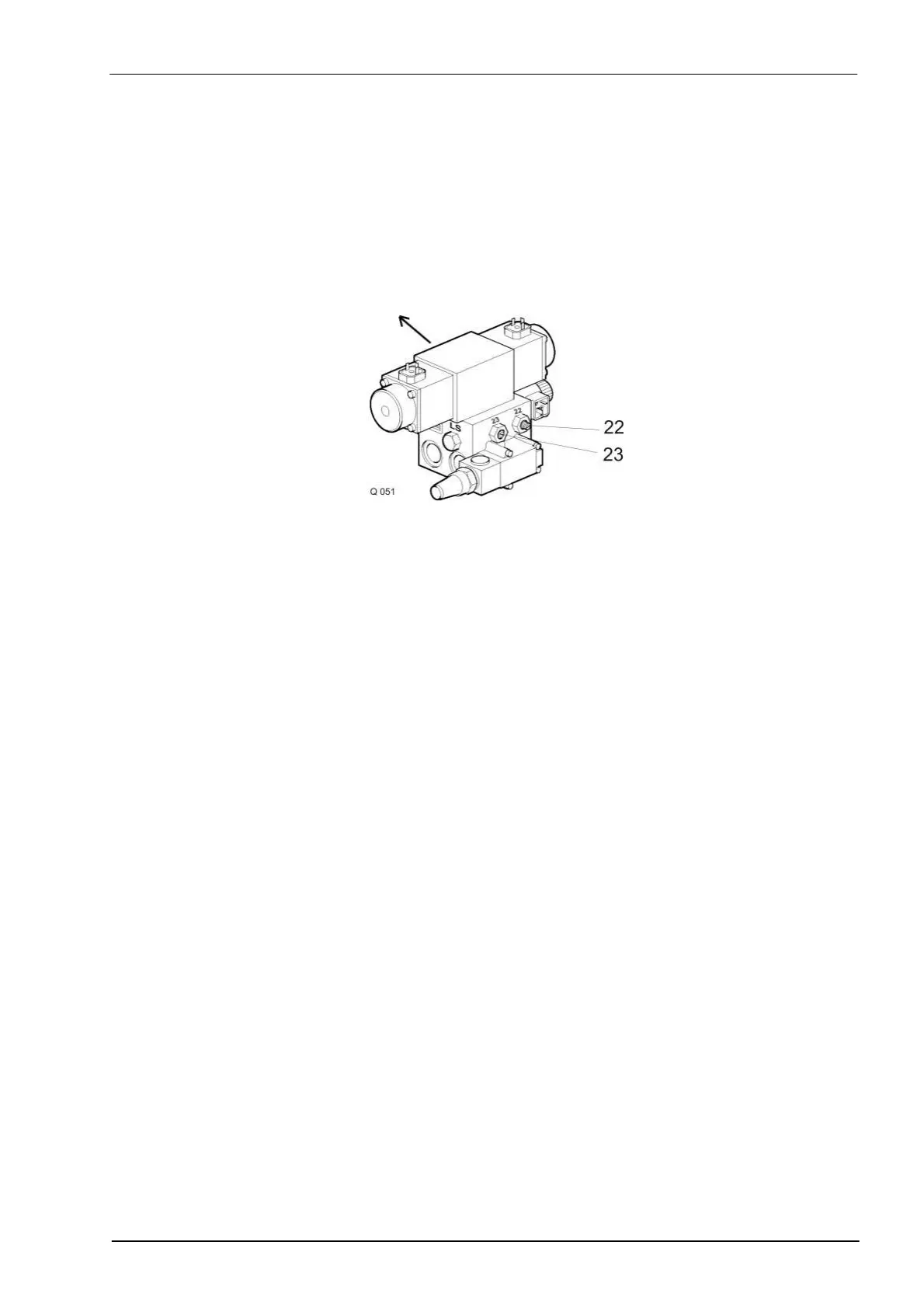

• Fully screw in set screw 22 on the hydraulic valve block (1).

• Unscrew set screw 23 on the hydraulic valve block (1)

3.0.4 Power beyond port Tractor with LS pump and CLAAS LS control line = Power beyond port:

• Fully screw in set screw 22 on the hydraulic valve block (1).

• Unscrew set screw 23 on the hydraulic valve block (1)

Connect the control line to the LS port of the control valve on the forage

wagon and to the LS port of the tractor.

The control line can be purchased from the CLAAS spare parts service:

• 1x 238 665.0 Threaded bushing

• 1x 238 788.0 Elbow nipple

• 1x 607 230.0 Hydraulic hose

• 1x 913 322.0 Hydraulic hose

• 1x 607 298.0 Plug

Free circulation

(solenoids not energized)

Remark: Oil supply from the tractor is via the additional control unit,

port (P).

The most favourable way of connecting is to let the return oil from the

forage wagon flow into a direct port to the tank (pressureless return line).

The oil quantity from the tractor should not exceed approx. 60 l/min., as

otherwise the circulation pressure and consequently the oil temperature

may increase.

The normal circulation pressure is below 20 bar (at an oil temperature of

50°C). The oil pressure switch (2) activates the electric system (terminal)

at a circulation pressure of 2 bar.

Loading...

Loading...