TIC QUANTUM Hydraulics

10/04 11-99

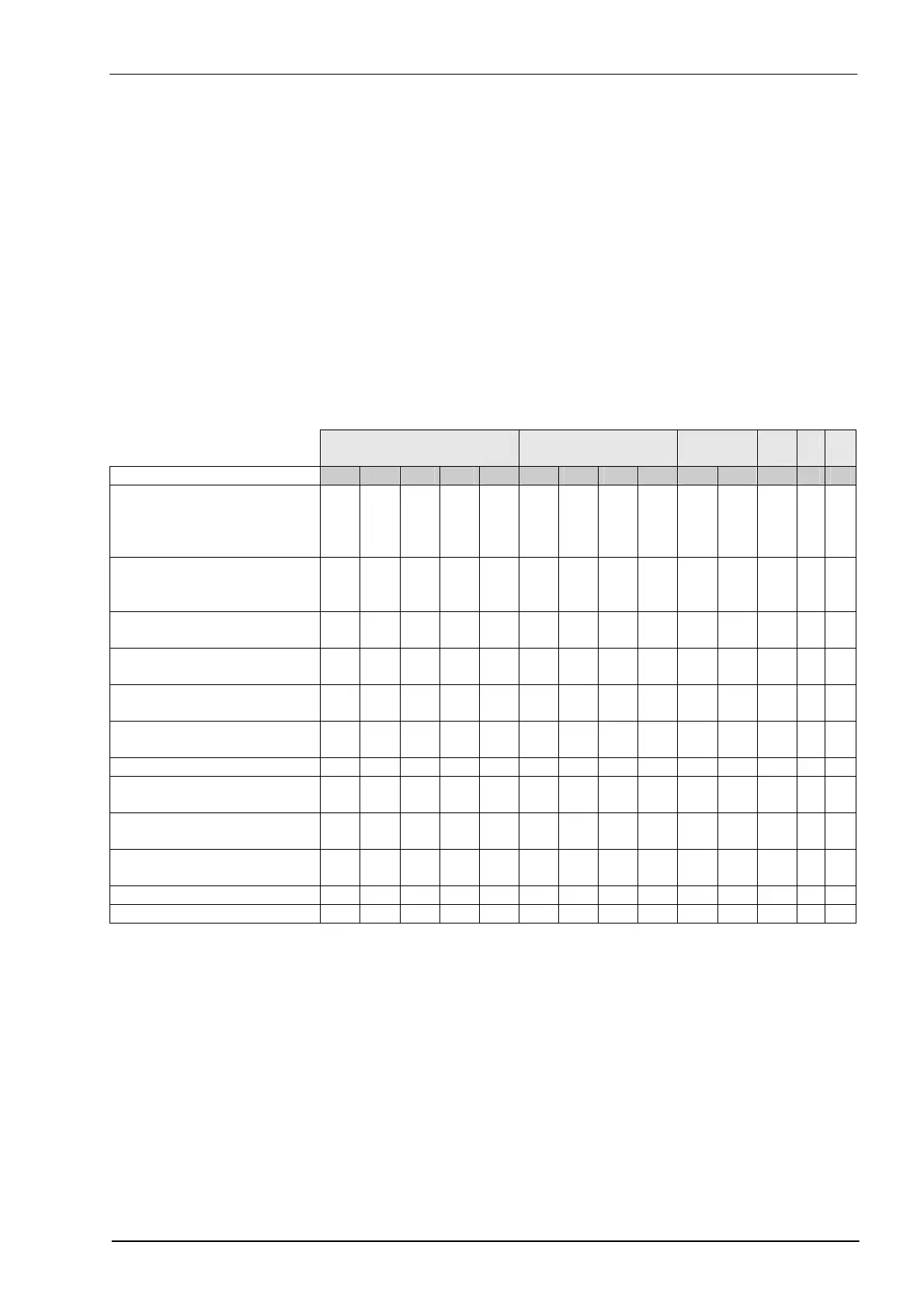

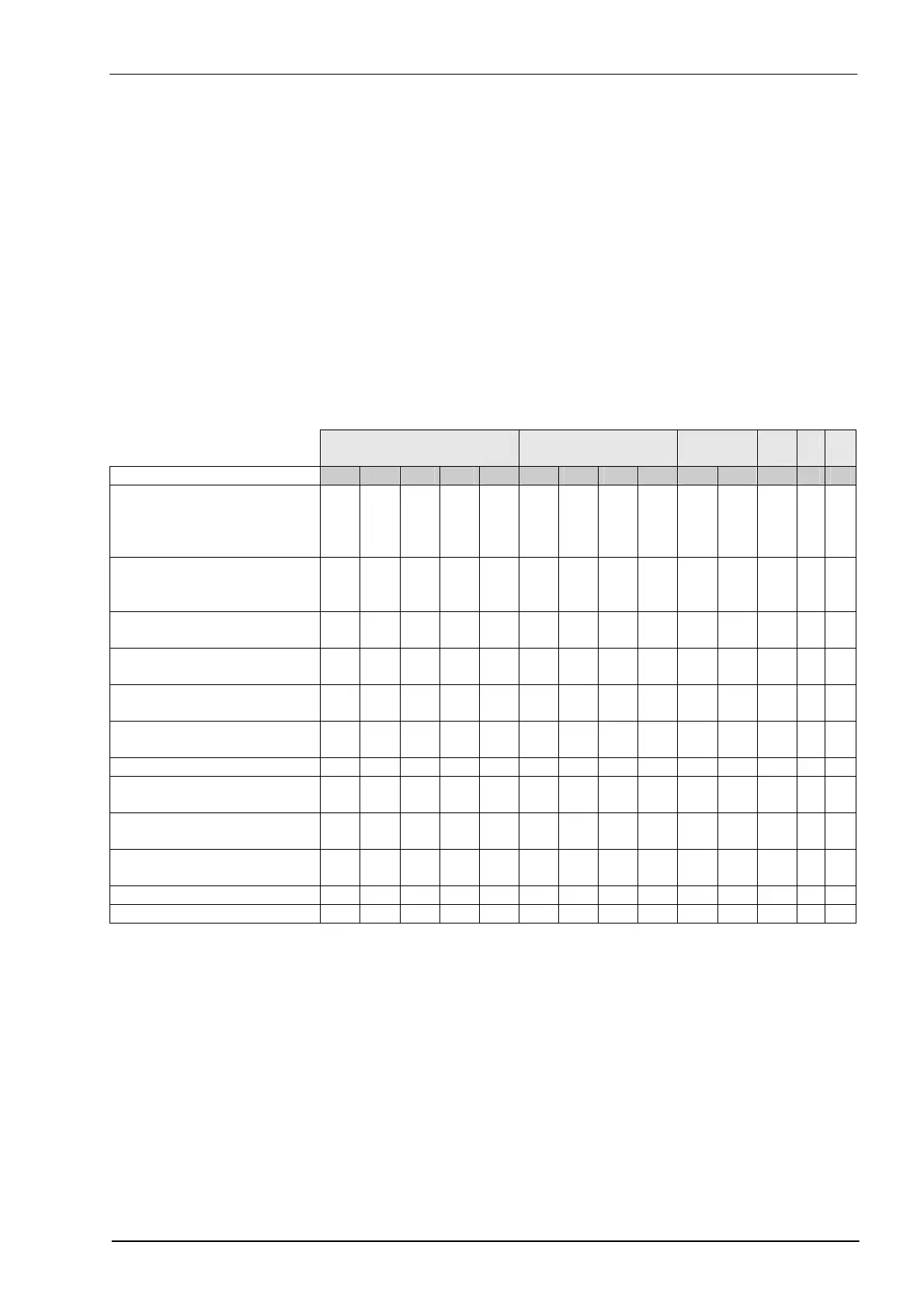

4.8 Faults and

remedies

4.8.1 Control system

(LP/LM08 with

SV02)

a

b

System screw turned in

System screw turned out

c Control spool jams

d Nozzle plugged

e Pressure valve will not close

f Insufficient electric power supply

g Pressure reducer works stiffly

h Control spool works stiffly

i Electric contact is not interrupted

k Solenoid will not switch

l Seated valve will not close

m Hydraulic motor defective

n Sealing plate, sealing nut or O-ring defective

o Block twisted, tie rods tightened too much

Circulation valve with

pressure relief valve

Directional control

valve

Seated

valve

a b c d e f g h i k l m n o

With open hydraulic system:

Tractor system pressure or

170 bar pressure build-up

with deactivated control units

1

With oil supply from “John

Deere tractors”: Steering

“wanders”

2

Hydraulic motor – does not

run

4 3 8

Hydraulic motor – runs only

in one direction

3

Hydraulic motor – does not

stop

3 6

Hydraulic motor – does not

reach max. speed

5

Cylinder – no function 4

Cylinder – does not remain

pressure-tight

7

No function from any

cylinder

4 3

No function from cylinders or

motor

3 3

Oil heating up 1

External leaks 8 9

Eliminating the faults 1 Back off screw

2 Turn in screw

3 Remove and clean

4 Check electric system, operate emergency shut-off

5 Insufficient electric power supply or pump capacity too low

6 Electric contact not interrupted, remove plug

7 Replace valve block

8 Replace

9 Check tie rod tightening torque (30 Nm)

Loading...

Loading...