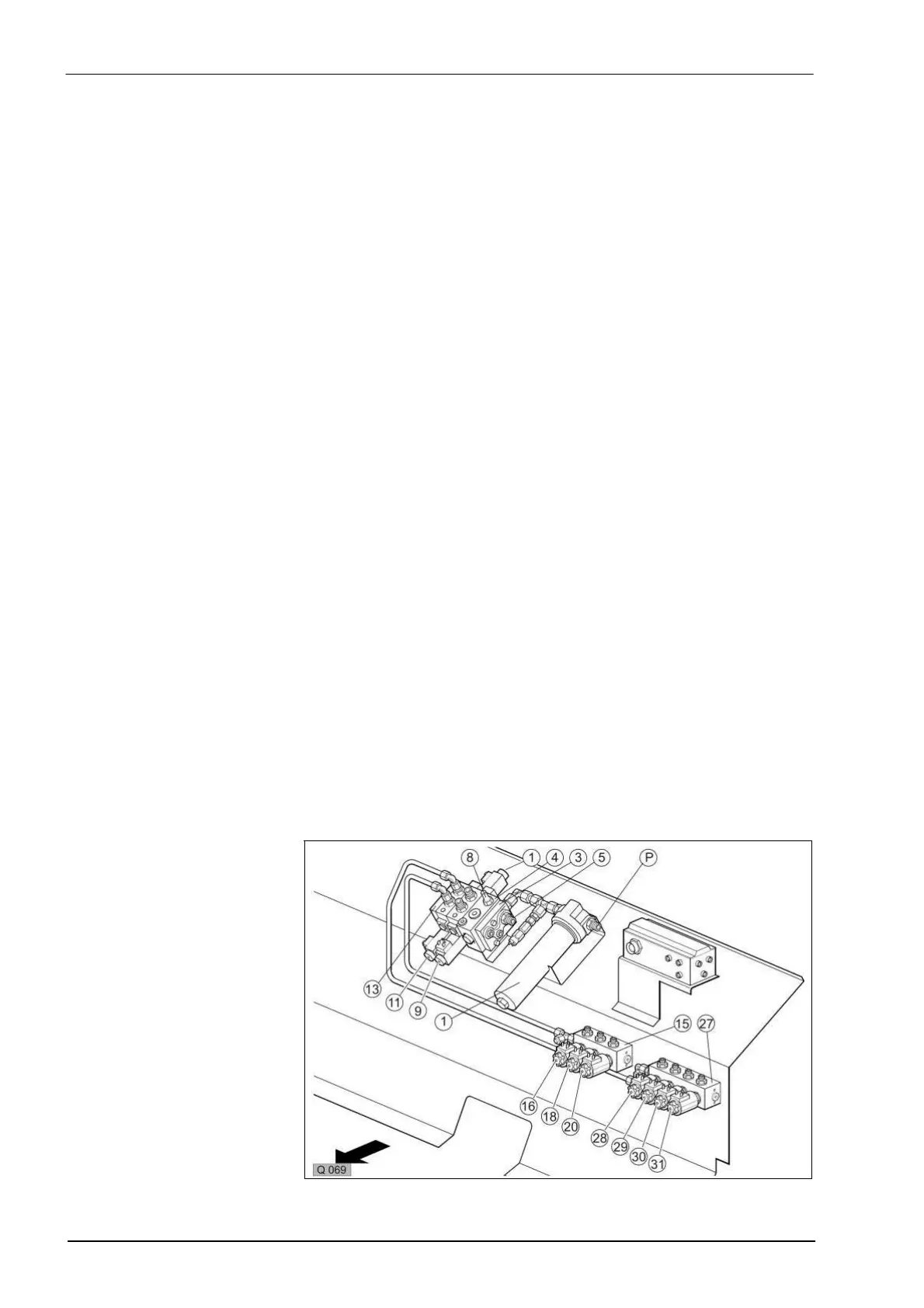

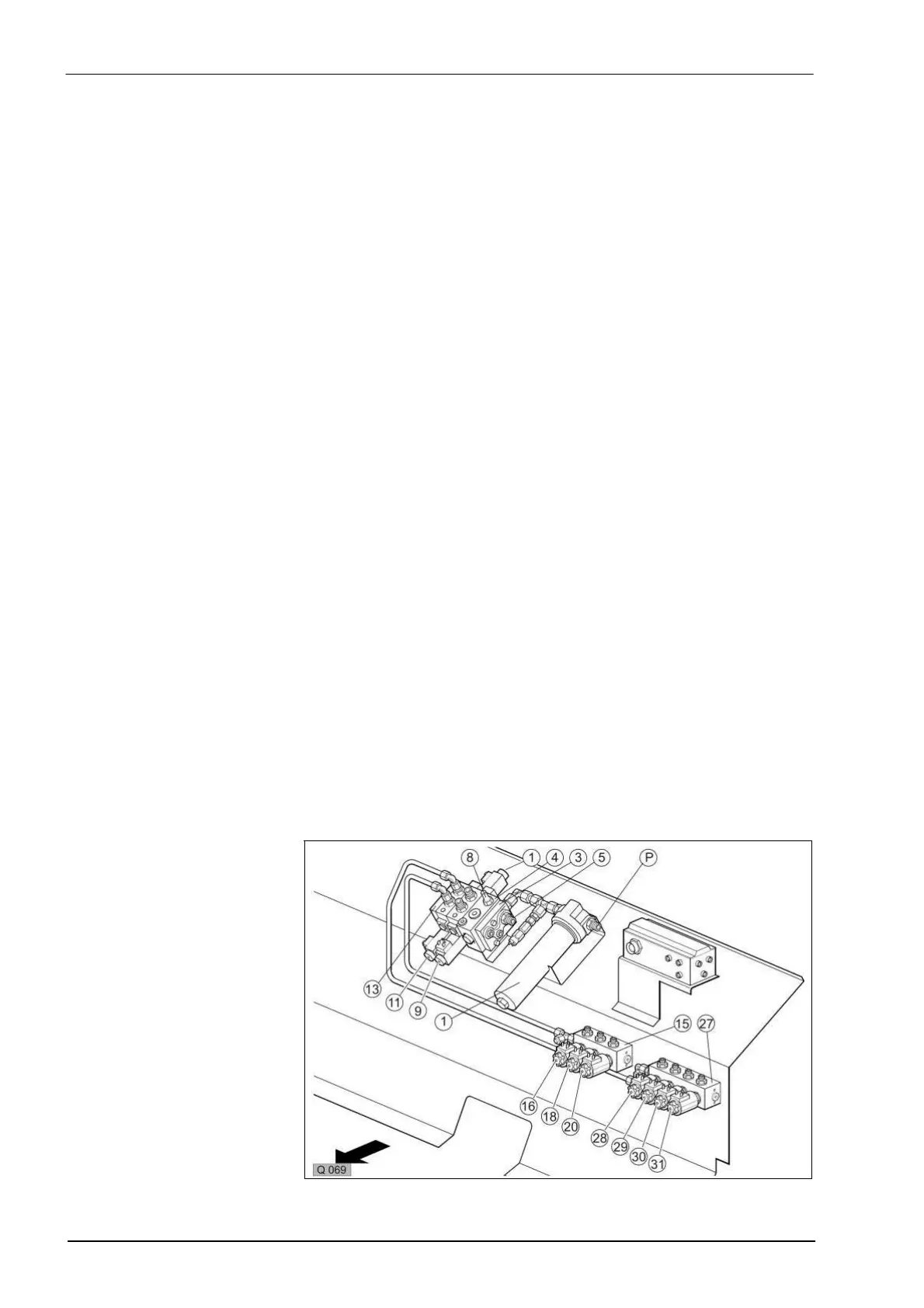

Hydraulics QUANTUM TIC

11-76 10/04

4.1 Circuit Diagram

P Tractor port (feed line)

T Tractor port (return line)

EW Tractor port (single acting)

1 Oil filter (110 l, 10 micro, resists diff. pressure of 30 bar)

2 Oil pressure switch 2 bar (normally open contact)

3 Connecting plate, BUCHER LU 08 PO OM 22

4 Circulation and pressure relief valve, Bucher LU 08 SBL-OM 22

5 Circulation valve spool

6 Orifice plate ø 0.8 mm, 0.6 l/min. control oil

6a LS port (load sensing)

7 Shut-off screw (closed hydraulic system, e.g. John Deere)

8 Pressure relief valve (p = 200 bar)

9 4/3 way proportional solenoid valve,

Bucher LP O8 E 4D 6363 OM 18 G12/12

10 Non-return valve

11 Load change valve

12 4/3 way solenoid valve, LM 08 E 4D 1010 OM 18612 (10 l/min.)

13 Connecting plate, BUCHER LU 08 PUT OM 22

14 Hydraulic motor, DANFOSS OMR 125 or OMR 160

14a Eaton 2-speed floor conveyor hydraulic motor 80/160 cm³

15 Seated valves, right block

16 2/2 way lower articulated drawbar solenoid valve

17 Articulated drawbar hydraulic cylinder

18 2/2 way close knife frame solenoid valve

19 Knife frame hydraulic cylinder

20 2/2 way open tailgate solenoid valve

21 Oil pressure switch 150 bar (normally open contact)

22 Tailgate hydraulic cylinder

27 Seated valves, left block

28 2/2 way raise articulated drawbar solenoid valve

29 2/2 way open knife frame solenoid valve

30 2/2 way close tailgate solenoid valve

31 2/2 way raise/lower pick-up solenoid valve

34 Couplers

35 Pick-up hydraulic cylinder

36 Orifice plate

M1 Floor conveyor forward solenoid coil

M2 Pressure port B solenoid coil

M3 Pressure port A solenoid coil

Loading...

Loading...