ProtoNode Gateway

750-426 11

2.3 Configuring Device Communications

2.3.1 Input COM Setting s on all Seria l De vice s C onnected to the Proto Node

All of the connected serial devices MUST have the same Baud Rate, Data Bits, Stop Bits, and Par-

ity settings as the ProtoNode.

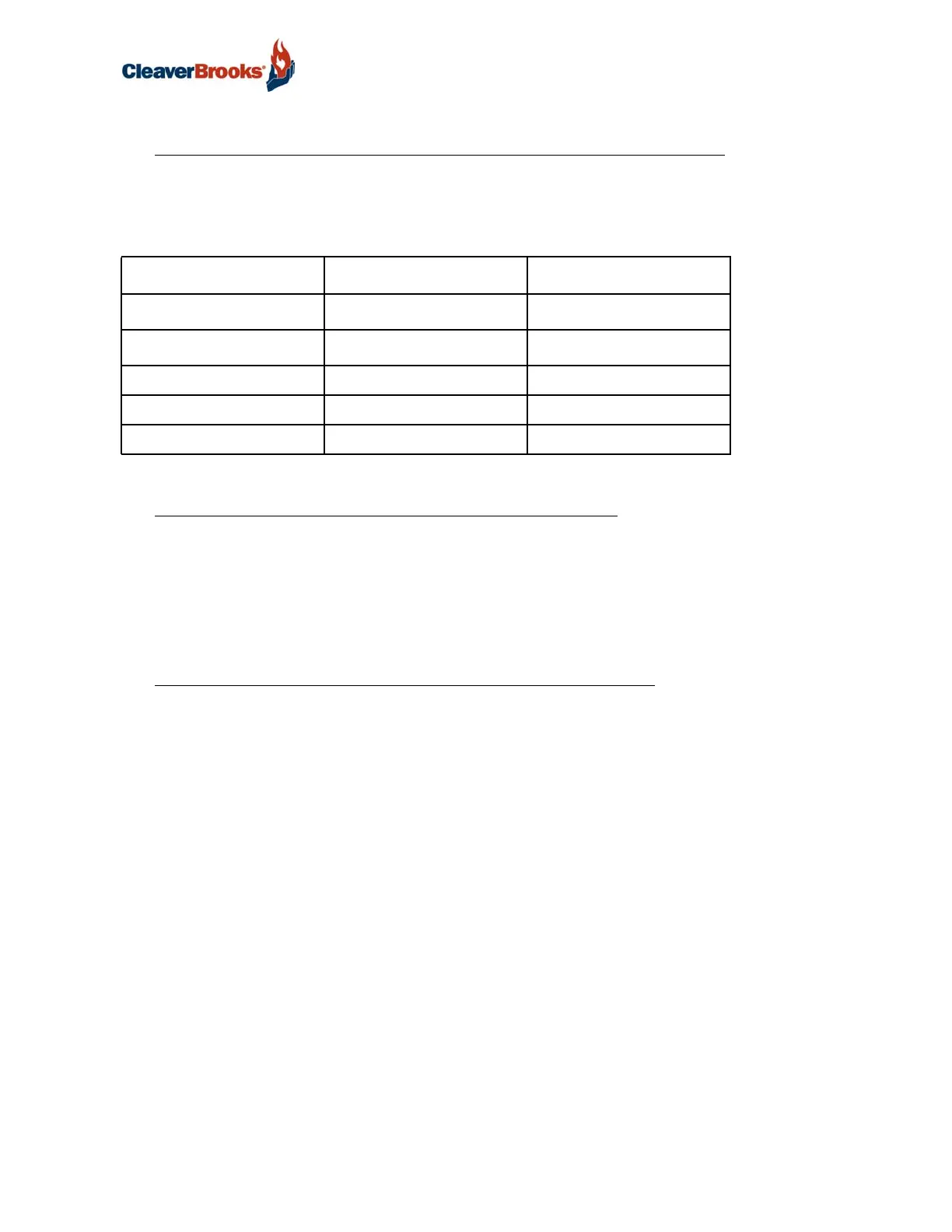

Figure 5 specifies the device serial port settings required to communicate with the ProtoNode.

FIGURE 5 - COM Settings

2.3.2 Set Modbus Node-ID for each device attached to the ProtoNode

Set Modbus Node-ID for each of the devices attached to ProtoNode. The Modbus Node-ID's need to

be uniquely assigned between 1 and 255. The Modbus Node-ID that is assigned for each device

needs to be documented. The Modbus Node-IDs assigned are used for designating the Device

Instance for BACnet/IP and BACnet MS/TP (Section 2.5.2)

The Metasys N2 and Modbus TCP/IP Field Protocol Node-IDs are automatically set to the same

value as the Node-ID of the device.

2.3.3 Set IP Address for each Ethernet Device Connected to the ProtoNode

Ensure devices are set to Modbus TCP/IP to communicate with the ProtoNode.

• The device needs to be on the same IP subnet as the ProtoNode and the configuration PC.

• Record the following device information to start the setup:

IP Address

IP port

Node-ID

NOTE: This information is required for Section 4.

2.4 Selecting the Desired Field Protocol

NOTE: If using the ProtoNode only for cloud-based data monitoring, Sections 2.4 and 2.5 may be

skipped.

• ProtoNode RER units use the “S” bank of DIP switches (S0 - S2) to select the Field Protocol.

See Figure 6 for the DIP switch settings.

The OFF position is when the DIP switches are set closest to the outside of the box.

• ProtoNode LER units do not use the “S” bank DIP switches to select a Field Protocol. On ProtoNode LER

units, these DIP switches are disabled; the Field Protocol is always LonWorks.

Port Setting Falcon Steam & Hydronic

Other Serial Devices

Protocol Modbus RTU Modbus RTU

Baud Rate 38400 9600

Parity None None

Data Bits 8 8

Stop Bits 1 1

Loading...

Loading...