Artiglio Master Code User Manual 51

UK

If, following automatic detection of the wheel/rim, the detected diameter needs to

be corrected, you must act on the buttons

and (Fig. 34a). To maintain the

correction in the next wheel recalls, the new diameter must be stored using the

button

(Fig. 34a). This command stores only the diameter variations and not

the tool position variations.

NOTICE

If the wheel dimensions are not identified (Fig. 34b), the

operator may proceed in one of the two following ways:

a. press the button

(Fig. 34b) and then press

the icon (Fig. 34a) again and repeat auto-

matic wheel data acquisition.

b. manually store wheel data:

- Use the arrows (Fig. 34b) to set the rim

diameter.

N.B.: The large arrows increase or decrease the size

by one inch, at each pressure step: The small arrows

increase or decrease the size by one tenth of an inch

each time they are pressed.

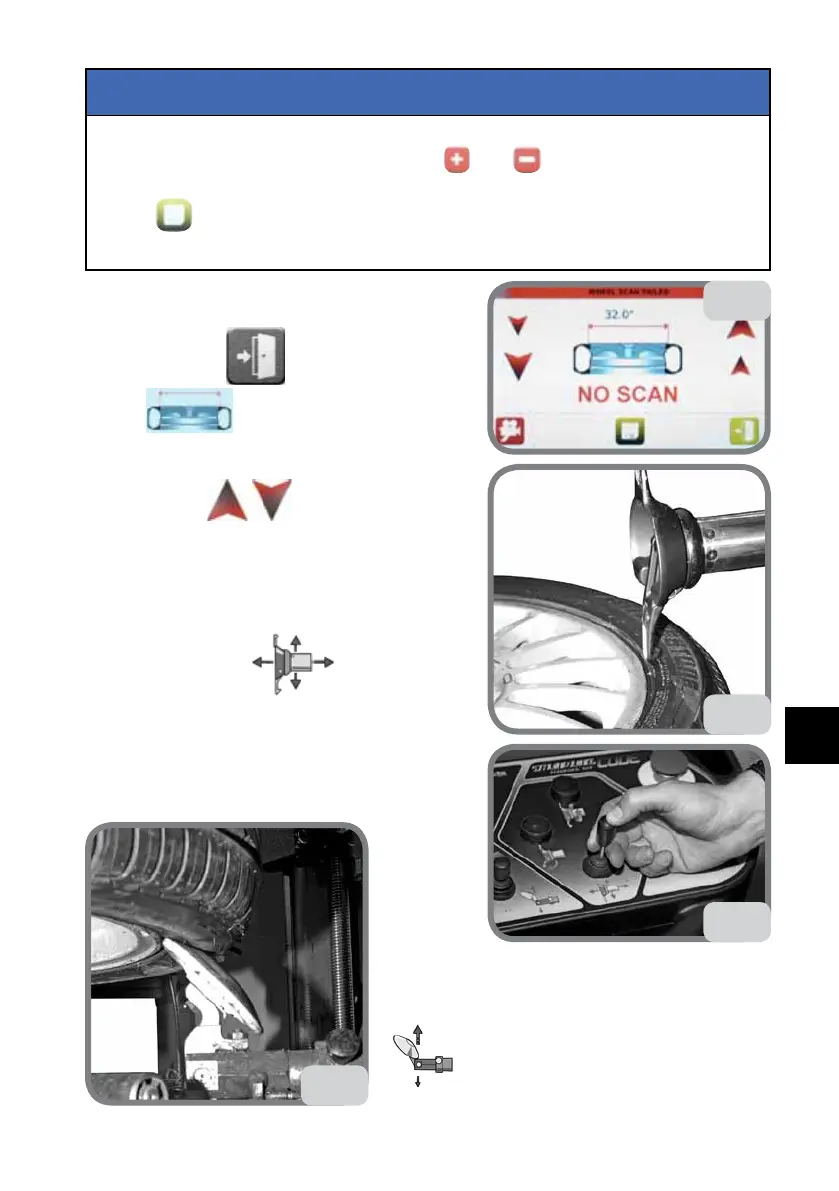

- Operate the control

on the push-but-

ton panel to position the tool on the wheel as shown

in Fig. 34c.

N.B.: To obtain more precise positioning

press the button located on the top part of the com-

mand (see Fig. 34d).-

-

- Act on the bottom bead breaker command

to position it as illustrated in Fig. 34e.

34c

34d

34e

34b

Loading...

Loading...