Artiglio Master Code User Manual 83

UK

This operation must ONLY be carried out in one

of the cases below:

1. Replacing the LASER triangulation sensor

2. Replacing one or both of the bead breaker

potentiometers

3. Replacing the tool head micro limit switches

4. Mechanical adjustment and/or replacement of

tool head parts

5. Replacing the LASER triangulation sensor move-

ment cylinder

Procedure:

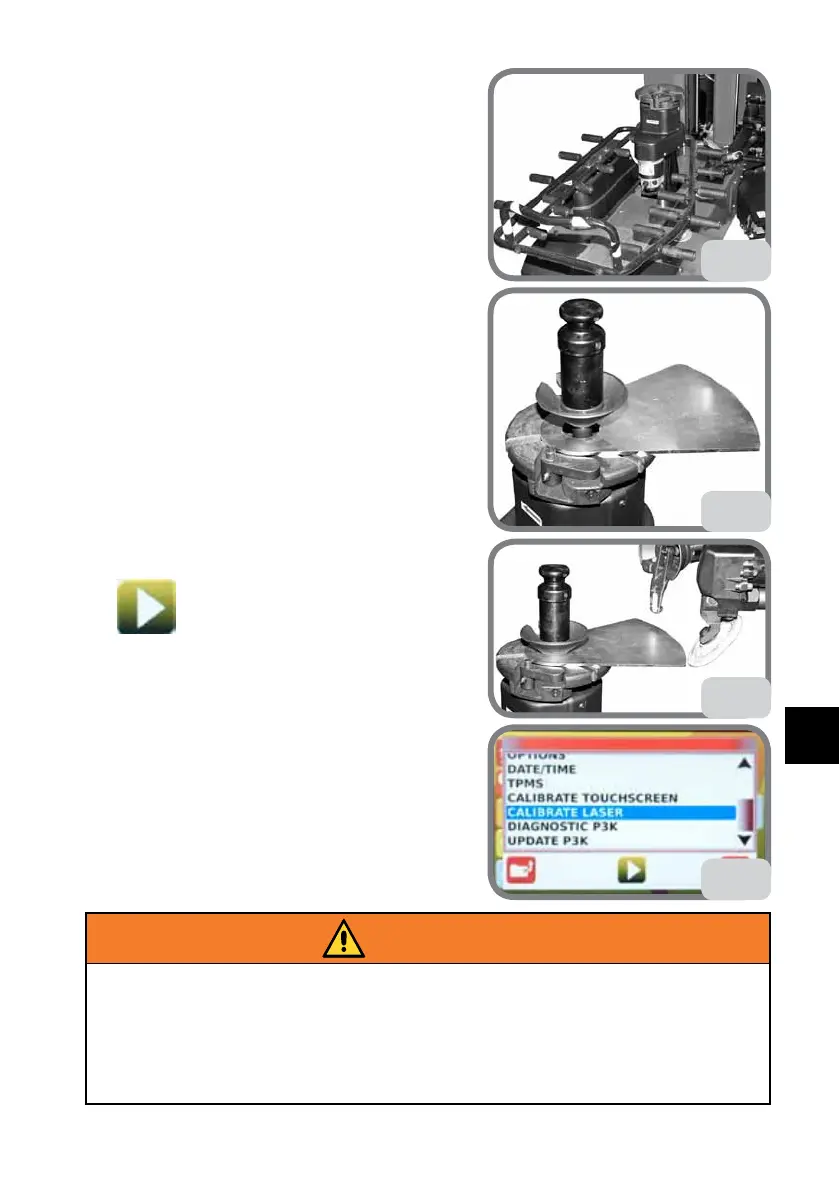

1. Position the lifter in the work position (Fig. 68).

2. Assemble the calibration template.

Use the M11 cast iron cone without the guard and

position the template with the chamfer facing

downwards (Fig. 68a).

Position it so it is interfacing with the bead break-

ers and head. (B, Fig. 68).

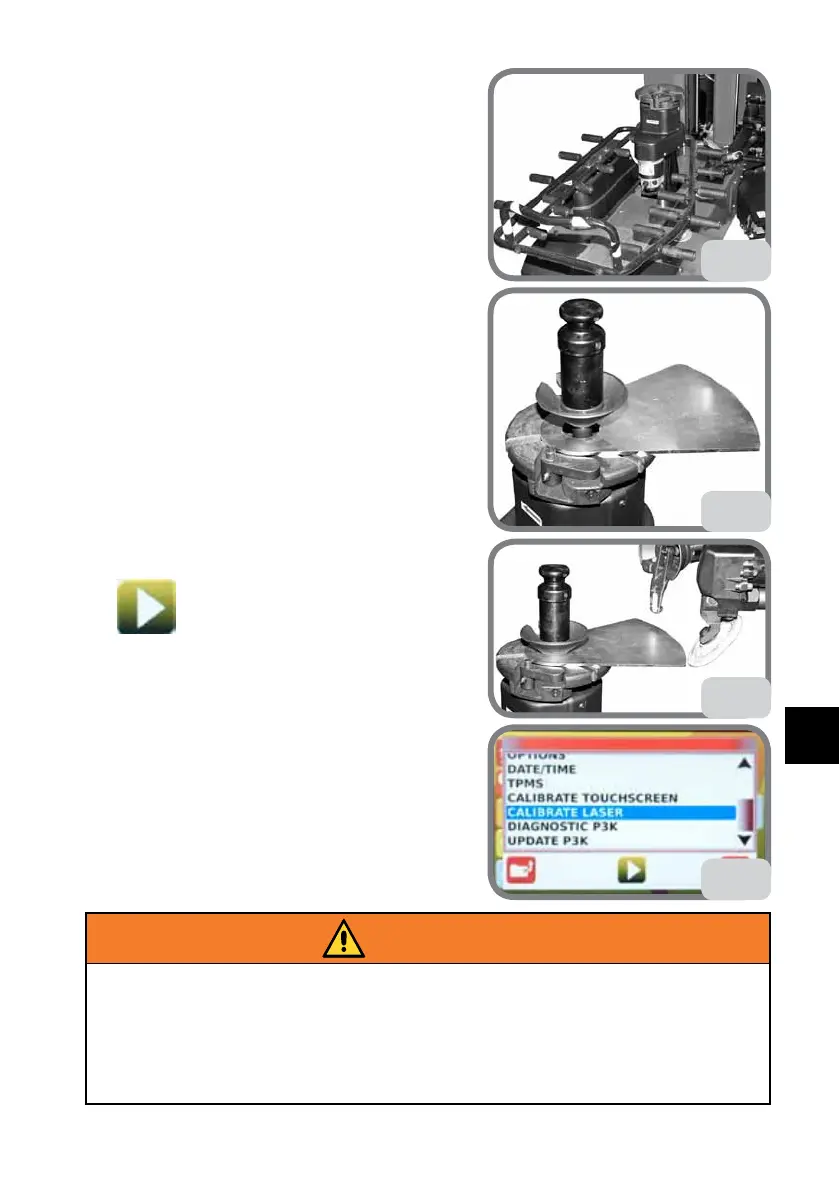

3. Select CALIBRATE LASER then press the confirm

key

(Fig. 68c).

CRUSHING HAZARD:

Some parts of the machine, such as the head, the bead breakers and turntable

move by themselves.

A beeper will sound to indicate when automatic movements are carried out.

Do not approach moving parts of the machine.

WARNING

68

68a

68c

68b

Loading...

Loading...