8-ORDINARY MAINTENANCE 8-7

COROB™ TATOCOLOR

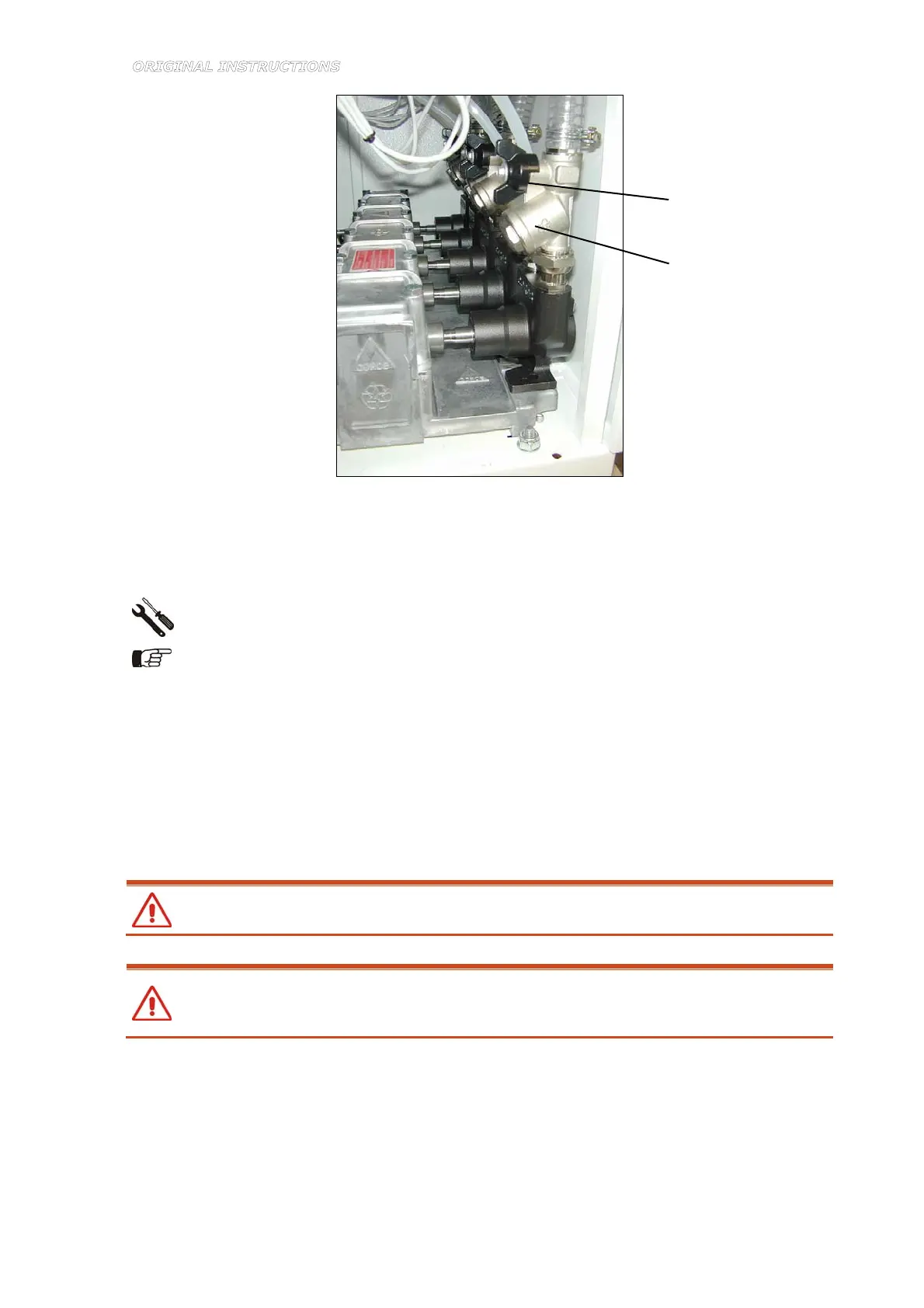

Figure 8-3

The frequency with which the filters must be cleaned depends on the colorants used on the

machine; the following factors affect the frequency: type of colorant (organic/inorganic), pigment

dispersion, sedimentation, viscosity, climatic conditions in the place where the machine is

installed, etc.

Only qualified personnel may clean the filters.

Check and eventually clean the pump filters after the machine has been running for 6

months; perform periodic maintenance thereafter, increasing or decreasing the intervals based

on the conditions found during the first check.

Clean the filters as follows:

1. Shut off the machine and unplug the power supply cable (chapter 6.4).

2. Use the screwdriver provided to open the panels of the canister sections.

3. Close all of the taps (2), located above the pumps, to stop the flow of colorant (Figure 8-3).

4. Connect the machine to the power mains and switch it on (chapter 6.2).

Machine ON with safety protections removed - RISK OF CRUSHING - Do not reach into the

dangerous area.

The machine will initialize when it is turned on (chapter 6.3).

Initialization with the protection panels removed from the machine is hazardous to the

operator, since moving mechanical parts are exposed. Keep your hands, clothing and hair

away from the machine motor compartment until it is shut off.

During recirculation the dispensing circuits (suction, delivery and recirculation) (Figure 8-4) empty

of colorant, which pours into the canisters through the recirculation connector (1) (Figure 8-5).

5. Open the canister section covers and remove the canister lids to make sure that the colorant

recirculation caused by initialization is enough to empty the dispensing circuits. When no

more colorant enters the canisters through the recirculation connectors, the circuits are

empty (Figure 8-5). If the recirculation caused by initialization is not sufficient, send an

additional colorant recirculation command from the application program.

1

2

Loading...

Loading...