3.11 Welding conditions of WB-P350L/P400L/P500L

3-44

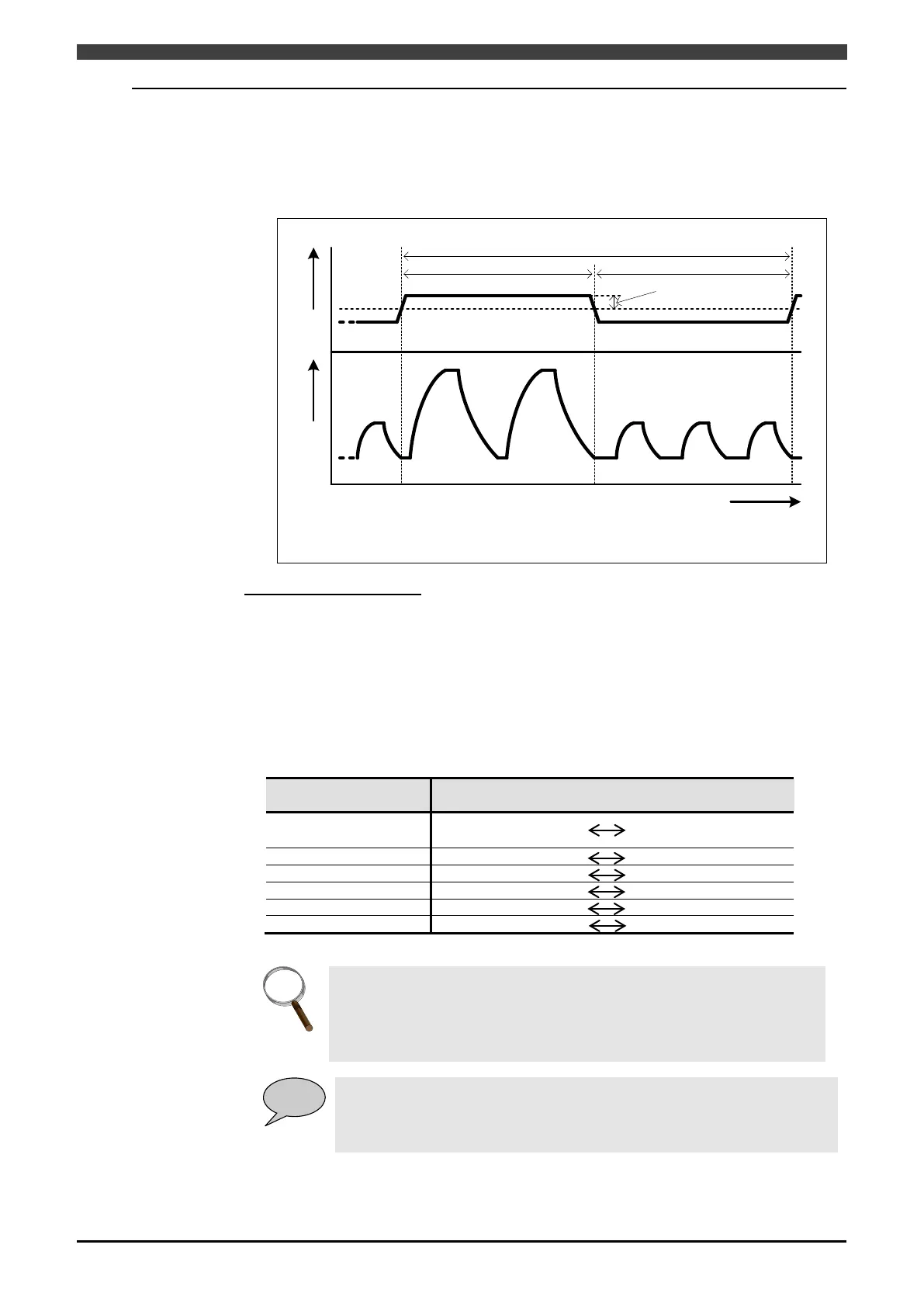

3.11.5 Waveform control with DC wave pulsed welding

DC wave pulsed welding is essentially pulsed welding, where a wave frequency period consists of

a low pulse section and high pulse section. The number of pulses in a low pulse section and high

pulse section in each period depends on the wave frequency and pulse conditions.

Waveform control (arc start - welding underway - crater treatment) is conducted as follows.

Time

One period

High pulse Low pulse

Amplitude rate

Welding current Wire speed

Fig. 3.11.3 Waveform control with the DC wave pulsed welding method

(arc start – welding underway – crater treatment)

What is the Amplitude Rate?

When the wave frequency is below 5 Hz, the wire feed speed is changed in wave pulsed

welding. By slightly adjusting the amplitude of this feed speed, welding results intended for

different purposes can be achieved.

The amplitude rate is meant for adjusting the shift value of the wire feed. Having 50% as its

standard measurement, adjustments can be made within the range from 0 to 100%. The

minimum adjustment unit is “1”.

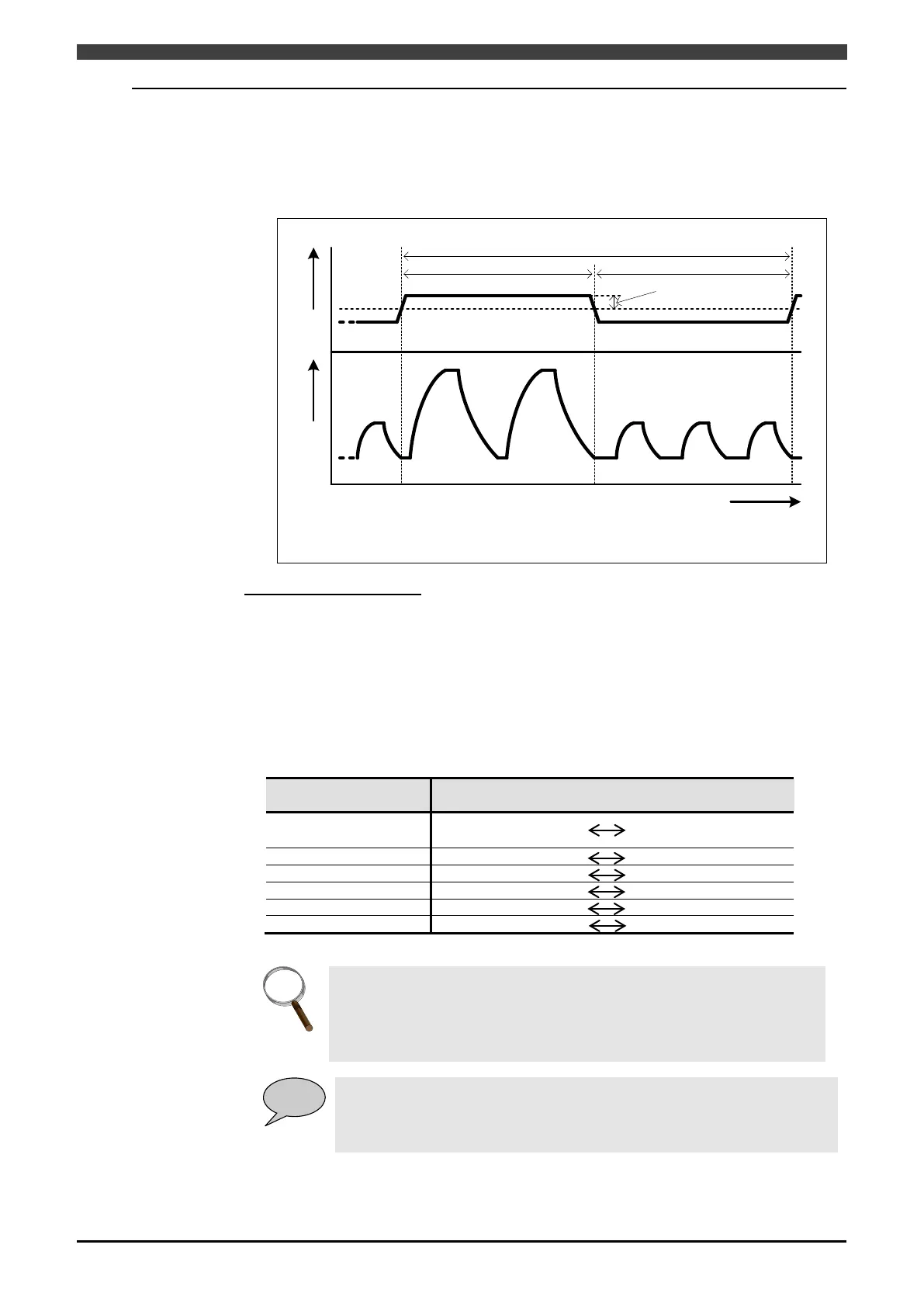

The relationship between the settings of the amplitude rate and the welding results are shown

in the table below. Adjust the amplitude rate accordingly to its intended purpose.

Table 3.11.4 Relationship between Amplitude Rate and Welding Results

Amplitude rate

Shift value of wire feed

(

)

Shift value of arc length

Even if “100% (Maximum)” is set for the mild and stainless steels, the melted

metal will flow before it hardens. Therefore, there are cases where the bead’s

ripple does not exceed the ripples that are created at “50% (Standard).”

When the registered welding power source is DP, it is not available to set the

amplitude rate.

Loading...

Loading...