1.4 Welding mode lists

1.4 Welding mode lists

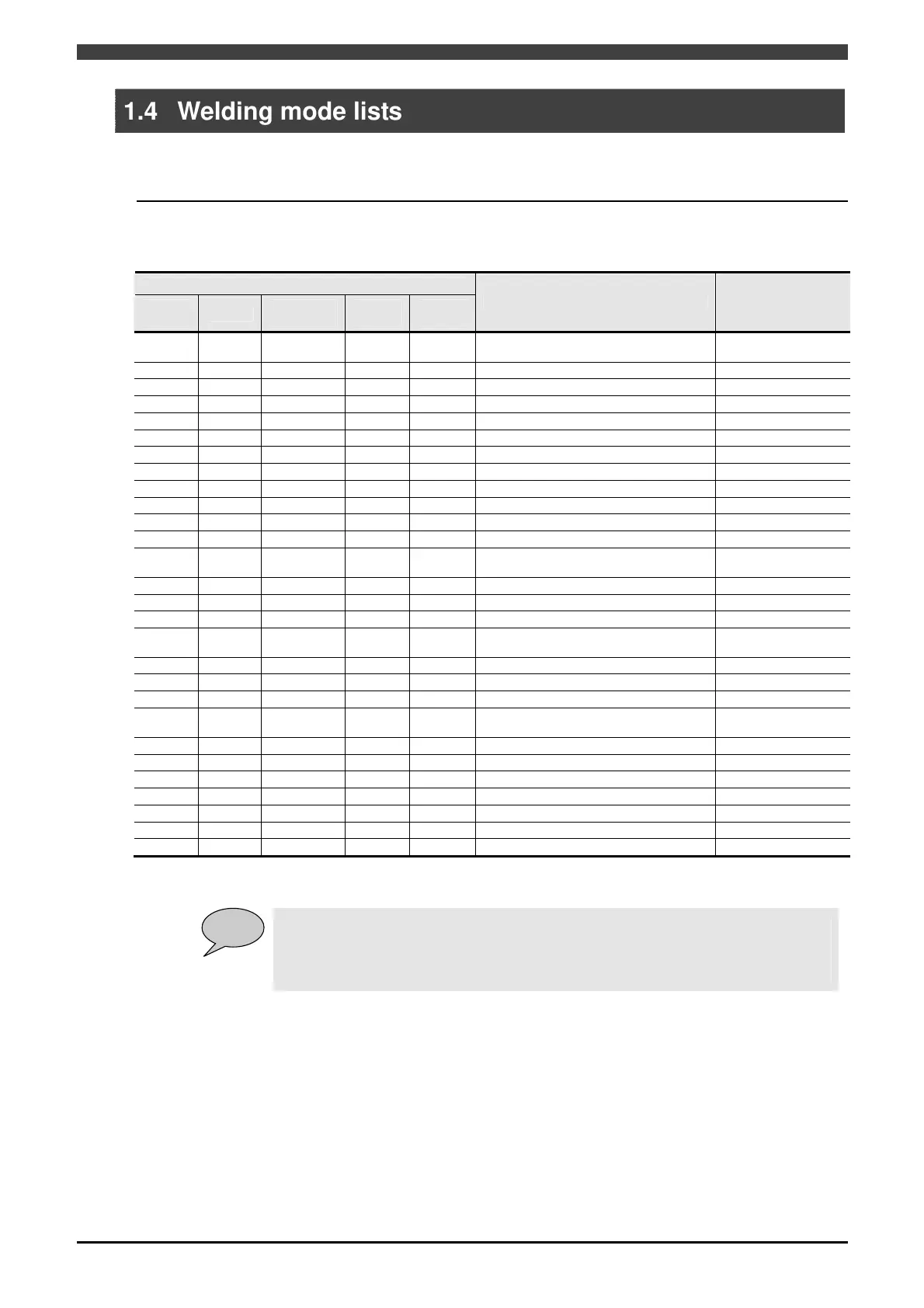

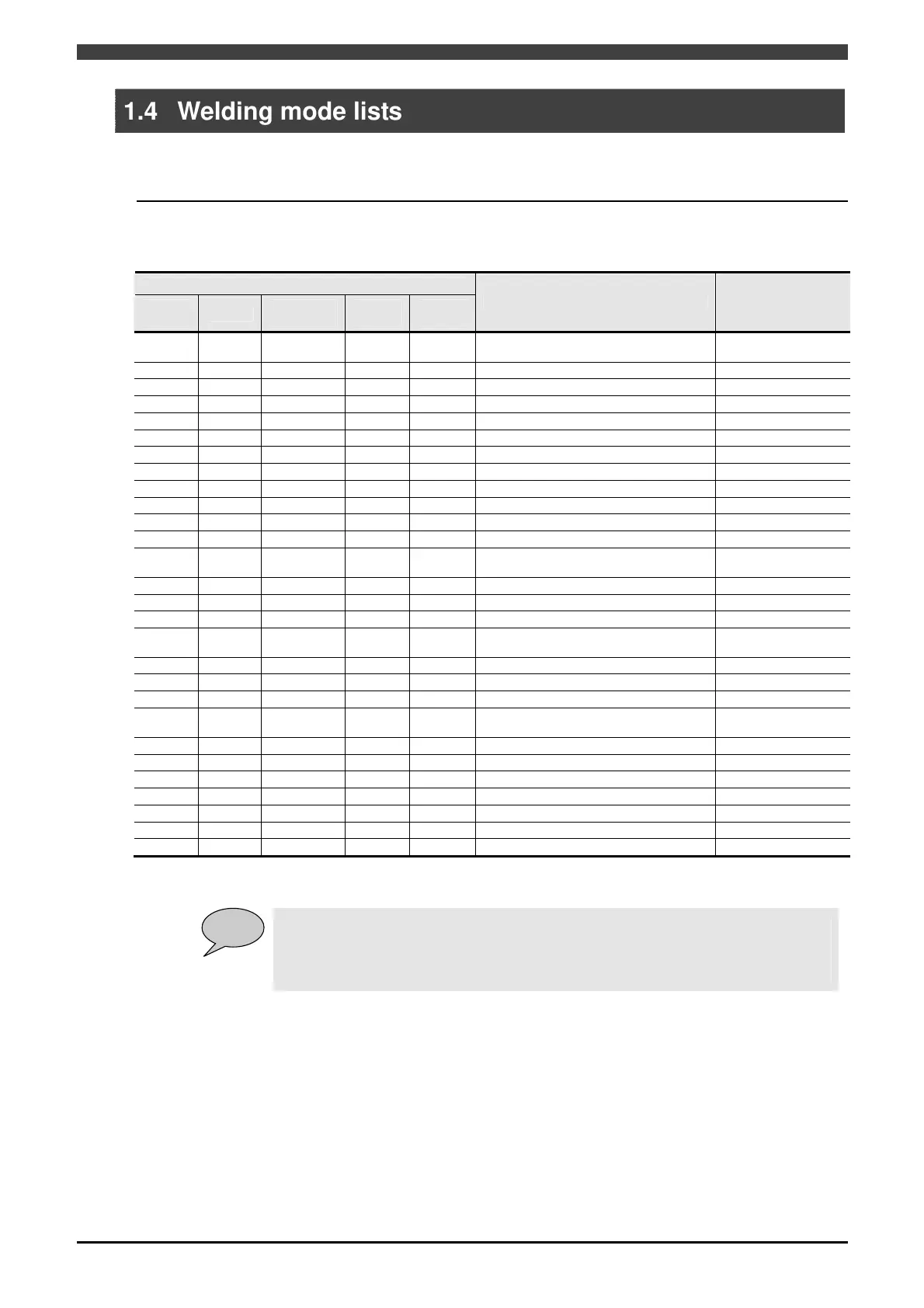

The welding modes shown below can be used with a Welbee Inverter series welding power source that is

connected to the robot controller using the interface.

1.4.1 Welding mode list of Welbee Inverter M350L / M400L

Table 1.4.1 Welbee Inverter M350L (specifications for Japan/CCC/Asia)

Welding mode

Welding

process

Gas

Wire

material

Wire

diameter

Travel

speed

Notes

Number of welding

Welding mode description

characteristic data in

AX21/FD11

DC Mild St

eel

Solid

CO2 0.8 High 350A Co2 DC φ0.8 (High#) $WTBD4401

(APCS)

〃 〃 〃 0.9 〃 350A Co2 DC φ0.9 (High#) $WTBD4402

〃 〃 〃 1.0 〃 350A Co2 DC φ1.0 (High#) $WTBD4403

〃 〃 〃 1.2 〃 350A Co2 DC φ1.2 (High#) $WTBD4404

〃 MAG 〃 0.8 〃 350A Mag DC φ0.8 (High#) $WTBD4406

〃 〃 〃 0.9 〃 350A Mag DC φ0.9 (High#) $WTBD4407

〃 〃 〃 1.0 〃 350A Mag DC φ1.0 (High#) $WTBD4408

〃 〃 〃 1.2 〃 350A Mag DC φ1.2 (High#) $WTBD4409

〃 MIG※1 SUS 0.8 〃 350A Mig_4 DC φ0.8 SuS (High#) $WTBD4410

〃 〃 〃 0.9 〃 350A Mig_4 DC φ0.9 SuS (High#) $WTBD4411

〃 〃 〃 1.0 〃 350A Mig_4 DC φ1.0 SuS (High#) $WTBD4412

〃 〃 〃 1.2 〃 350A Mig_4 DC φ1.2 SuS (High#) $WTBD4413

〃 CO2

Mild Steel

Solid

0.8 Standard 350A Co2 DC φ0.8 (Low#) $WTBD4419

〃 〃 〃 0.9 〃 350A Co2 DC φ0.9 (Low#) $WTBD4420

〃 〃 〃 1.0 〃 350A Co2 DC φ1.0 (Low#) $WTBD4421

〃 〃 〃 1.2 〃 350A Co2 DC φ1.2 (Low#) $WTBD4422

Mild St

eel

Cored

DC 〃 1.2 〃 $WTBD4424

350A Co2 DC φ1.2 (Cored) (Low#)

〃 〃 〃 1.4 〃 $WTBD4425

350A Co2 DC φ1.4 (Cored) (Low#)

350A Co2 DC φ0.9 SuS(Cored)

(Low#)

〃 〃 SUS Cored 0.9 〃 $WTBD4429

350A Co2 DC φ1.2 SuS(Cored)

(Low#)

〃 〃 〃 1.2 〃 $WTBD4430

DC Mild Steel

Solid

MAG 0.8 〃 350A Mag DC φ0.8 (Low#) $WTBD4432

(APCS)

〃 〃 〃 0.9 〃 350A Mag DC φ0.9 (Low#) $WTBD4433

〃 〃 〃 1.0 〃 350A Mag DC φ1.0 (Low#) $WTBD4434

〃 〃 〃 1.2 〃 350A Mag DC φ1.2 (Low#) $WTBD4435

〃 MIG※1 SUS 0.8 〃 350A Mig_4 DC φ0.8 SuS (Low#) $WTBD4436

〃 〃 〃 0.9 〃 350A Mig_4 DC φ0.9 SuS (Low#) $WTBD4437

〃 〃 〃 1.0 〃 350A Mig_4 DC φ1.0 SuS (Low#) $WTBD4438

〃 〃 〃 1.2 〃 350A Mig_4 DC φ1.2 SuS (Low#) $WTBD4439

※1 98%Ar, 2%O

2

POINT

Normally, use the welding characteristic data given in Table 1.4.1dedicated to “High”

application. The ones for “Standard” application must be used only when the welding

speed is low (50cm/min or lower in general), which causes unstable welding

performance.

1-12

Loading...

Loading...