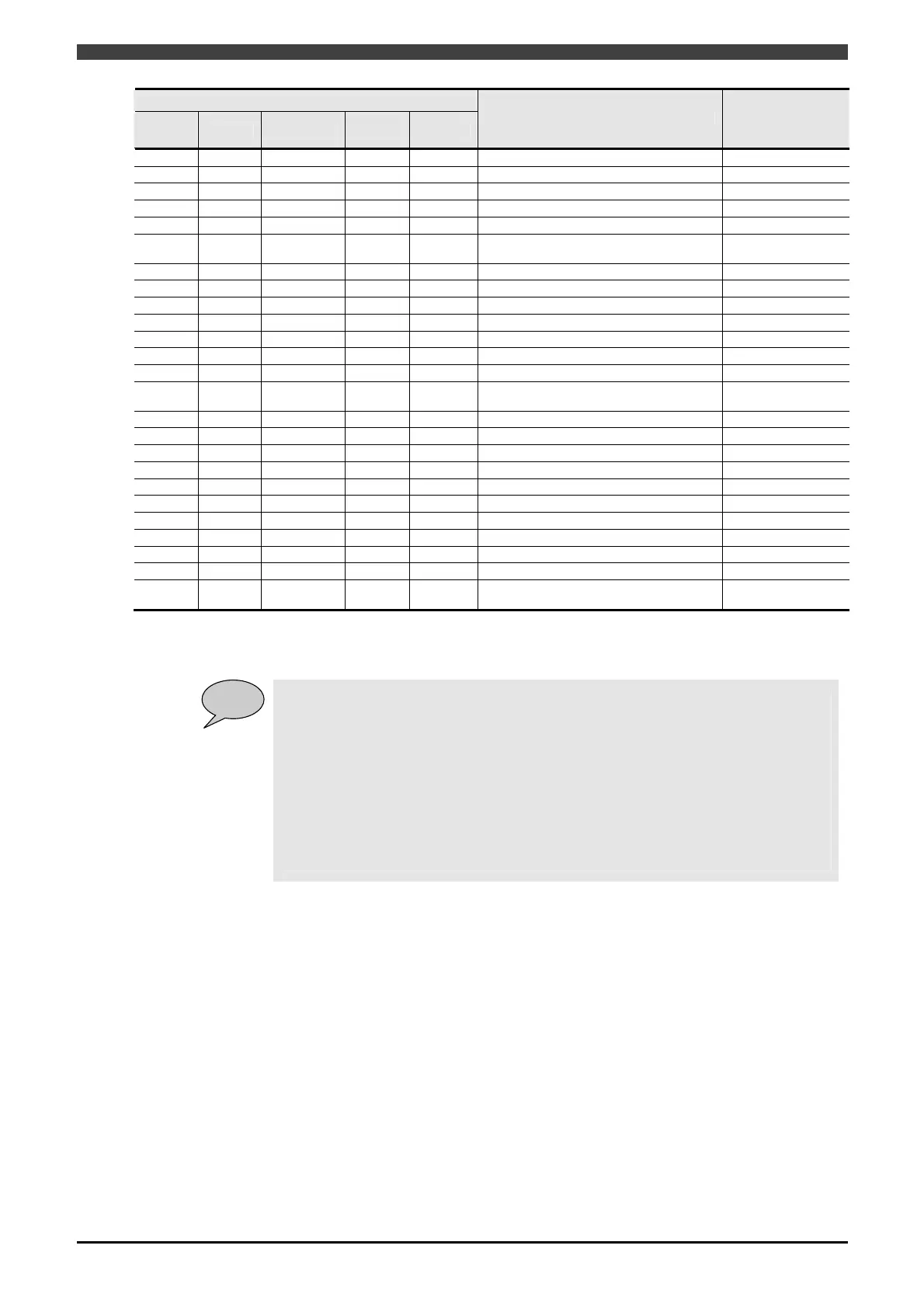

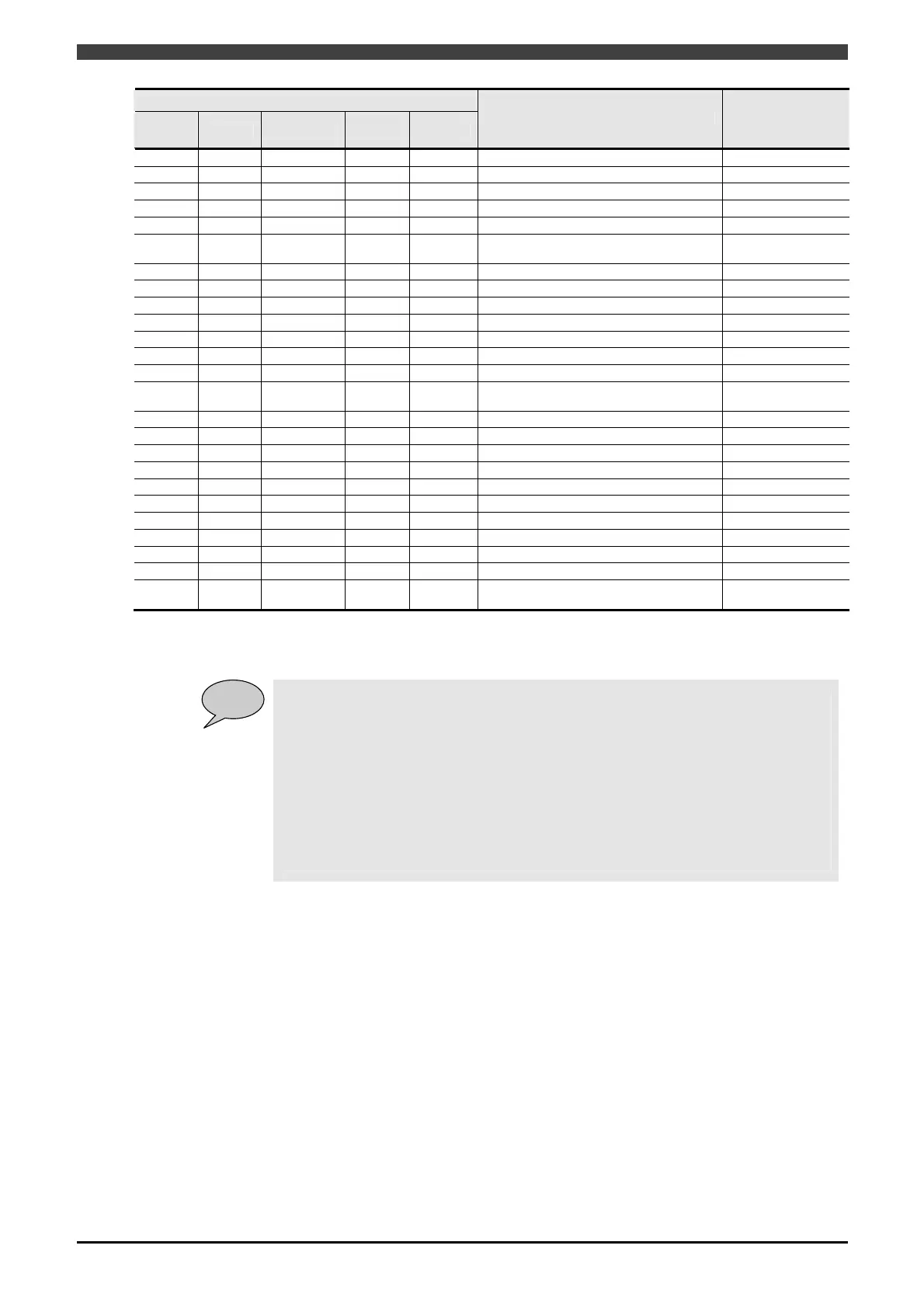

1.4 Welding mode lists

1-14

Welding mode

Welding

process

Gas

Wire

material

Wire

diameter

Travel

speed

Notes

Number of welding

Welding mode description

characteristic data

in AX21/FD11

DC MAG SUS Cored 1.2 Standard 350A Mag DCφ1.2 SuS (Cor

ed) (Low) $WTBD4522

〃 MIG※2 Hard Alm 1.2 〃 350A Mig_3 DCφ1.2 Hard Al (Low) $WTBD4540

〃 〃 〃 1.6 〃 350A Mig_3 DCφ1.6 Hard Al (Low) $WTBD4541

〃 〃 Soft Alm 1.2 〃 350A Mig_3 DCφ1.2 Soft Al (Low) $WTBD4542

〃 〃 〃 1.6 〃 350A Mig_3 DCφ1.6 Soft Al (Low) $WTBD4543

〃 CO2

Mild Steel

Solid

Extended

cable

0.8 350A Co2 DC φ0.8 (Low*) $WTBD4552

〃 〃 〃 0.9 〃 350A Co2 DC φ0.9 (Low*) $WTBD4553

〃 〃 〃 1.0 〃 350A Co2 DC φ1.0 (Low*) $WTBD4554

〃 〃 〃 1.2 〃 350A Co2 DC φ1.2 (Low*) $WTBD4555

〃 MAG 〃 0.8 〃 350A Mag DC φ0.8 (Low*) $WTBD4558

〃 〃 〃 0.9 〃 350A Mag DC φ0.9 (Low*) $WTBD4559

〃 〃 〃 1.0 〃 350A Mag DC φ1.0 (Low*) $WTBD4560

〃 〃 〃 1.2 〃 350A Mag DC φ1.2 (Low*) $WTBD4561

Mild St

eel

Cored

〃 〃 1.2 〃 350A Mag DC φ1.2 (Cored) (Low*) $WTBD4562

〃 〃 〃 1.4 〃 350A Mag DC φ1.4 (Cored) (Low*) $WTBD4563

〃 〃 SUS Cored 1.2 〃 350A Mag DC φ1.2 SuS (Cored) (Low*) $WTBD4564

〃 MIG※1 SUS 0.8 〃 350A Mig_4 DC φ0.8 SuS (Low*) $WTBD4577

〃 〃 〃 0.9 〃 350A Mig_4 DC φ0.9 SuS (Low*) $WTBD4578

〃 〃 〃 1.0 〃 350A Mig_4 DC φ1.0 SuS (Low*) $WTBD4579

〃 〃 〃 1.2 〃 350A Mig_4 DC φ1.2 SuS (Low*) $WTBD4580

〃 MIG※2 Hard Alm 1.2 〃 350A Mig_3 DCφ1.2 Hard Al (Low*) $WTBD4586

〃 〃 〃 1.6 〃 350A Mig_3 DCφ1.6 Hard Al (Low*) $WTBD4587

〃 〃 Soft Alm 1.2 〃 350A Mig_3 DCφ1.2 Soft Al (Low*) $WTBD4588

〃 〃 〃 1.6 〃 350A Mig_3 DCφ1.6 Soft Al (Low*) $WTBD4589

DC

MIG※1 Ferrite 0.9 High 350A Mig_4 DC φ0.9 Ferrite (High#) $WTBD4598

(APCS)

※1 98%Ar, 2%O

2

※2 100%Ar

POINT

Normally, use the welding characteristic data given in Table 1.4.2 dedicated to “High”

application. The ones for “Standard” application must be used only when the welding

speed is low (50cm/min or lower in general), which causes unstable welding

performance.

Also, welding performance may become unstable when using the extended power cable

depending on the layout condition of cables (when the total length exceeds 30m or the

cable is coiled). In that case, voltage adjustment will normally bring about stable

condition. However, use the welding characteristic data dedicated to “Standard:

extension” application if the welding performance is not yet stable. In order to register

“Standard: extension” application, change the operator qualification to “

SPECIALIST

”.)

Loading...

Loading...