Chapter 2.0 Compressor Fundamentals

Compressoroperationbeginswithademandsignalappliedtothecompressor.Thestartupsequenceis

configurableinthestartupsettings.SeetheOEMProgrammingManualforfurtherdetails.

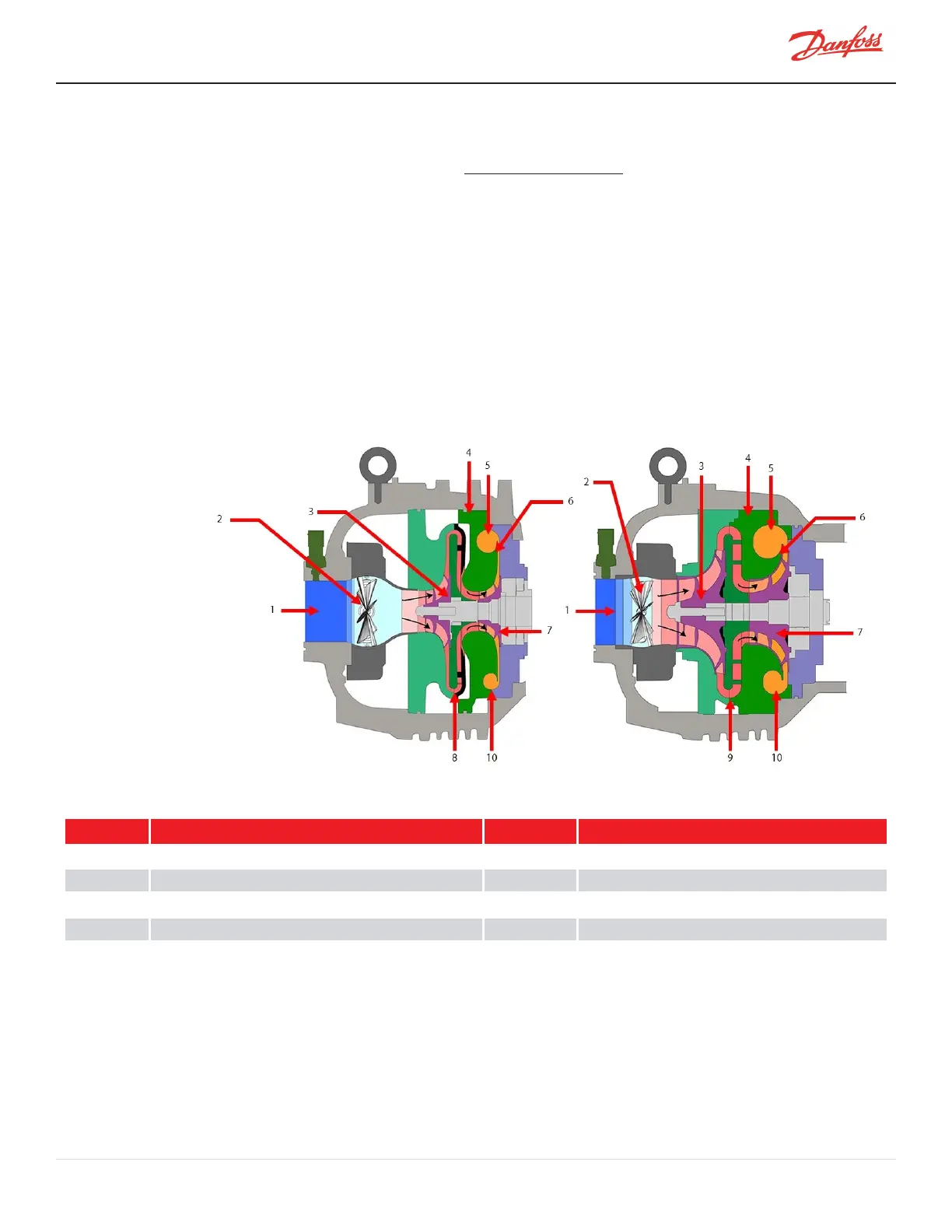

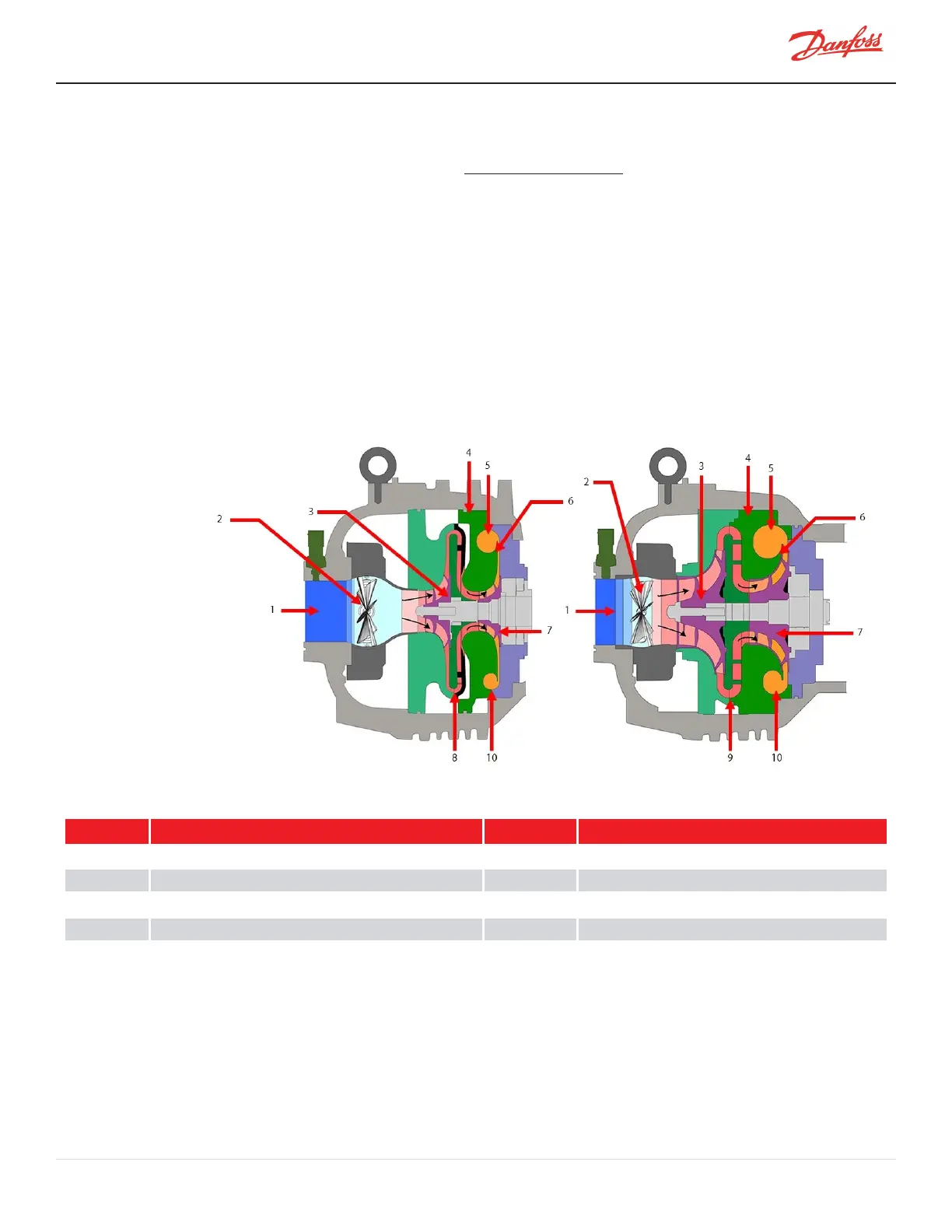

2.1 Main Fluid Path

Thecompressorisatwo-stagecentrifugaltypecompressorutilizingvariablespeedastheprinciplemeansof

capacitycontrolwithinletguidevanes(IGVs)assistingwhenrequired.Refrigerantentersthefirststagesuctionside

ofthecompressorasalow-pressure,low-temperature,superheatedvapor.ItthenpassesthroughvariableIGVsthat

assistcompressorcontrolatpart-loadconditions.Bothimpellersaremountedonacommonshaft.Vaporpasses

throughthefirst-stageimpellerwherevelocityenergyisaddedtotherefrigerant.Thisisconvertedtoan

intermediatepressureinthefirst-stagevolute.Vaporthenentersthesecond-stageimpellerthroughadiffuser.In

thesecondstage,impellervelocityenergyisagainaddedtotherefrigerantandconvertedtothefinaldischarge

pressureinthedischargediffuserandvolute.Fromthesecond-stageimpeller,refrigerantpassesasahighpressure,

superheatedvaportothesystemdischargeline.

Figure 2-1 Compressor Fluid Paths

Table 2-1 Compressor Fluid Paths

No. Component No. Component

1

LowPressure/LowTemperatureGas

6 High-Pressure/HighTemperatureGas

2

InletGuideVanes(IGVs)

7 Second-StageImpeller

3

First-StageImpeller

8 VanedDiffuser

4

VoluteAssembly

9 VanelessDiffuser

5 DischargePort 10 De-SwirlVanes

2.2 Motor and Power Electronics Cooling

Liquidrefrigerant,havingatleast3.5°Kelvin/6.3°Rankinesub-coolingatconnectionpoint,mustbepipedtothe

compressorcoolinginletconnection.Thisconnectionisa1/2inchO-ringfaceseal(ORFS)connectionwithabuilt-in

strainer.RefertoFigure2-2CoolingInletAdapteronpage34foranexampleofthecoolinginletadapter.

M-SV-001-EN Rev. H-1/23/2023 Page 33 of 294

Loading...

Loading...