5. RemovetheLiquidLineconnectionfromthecompressorandinspectthestrainer.

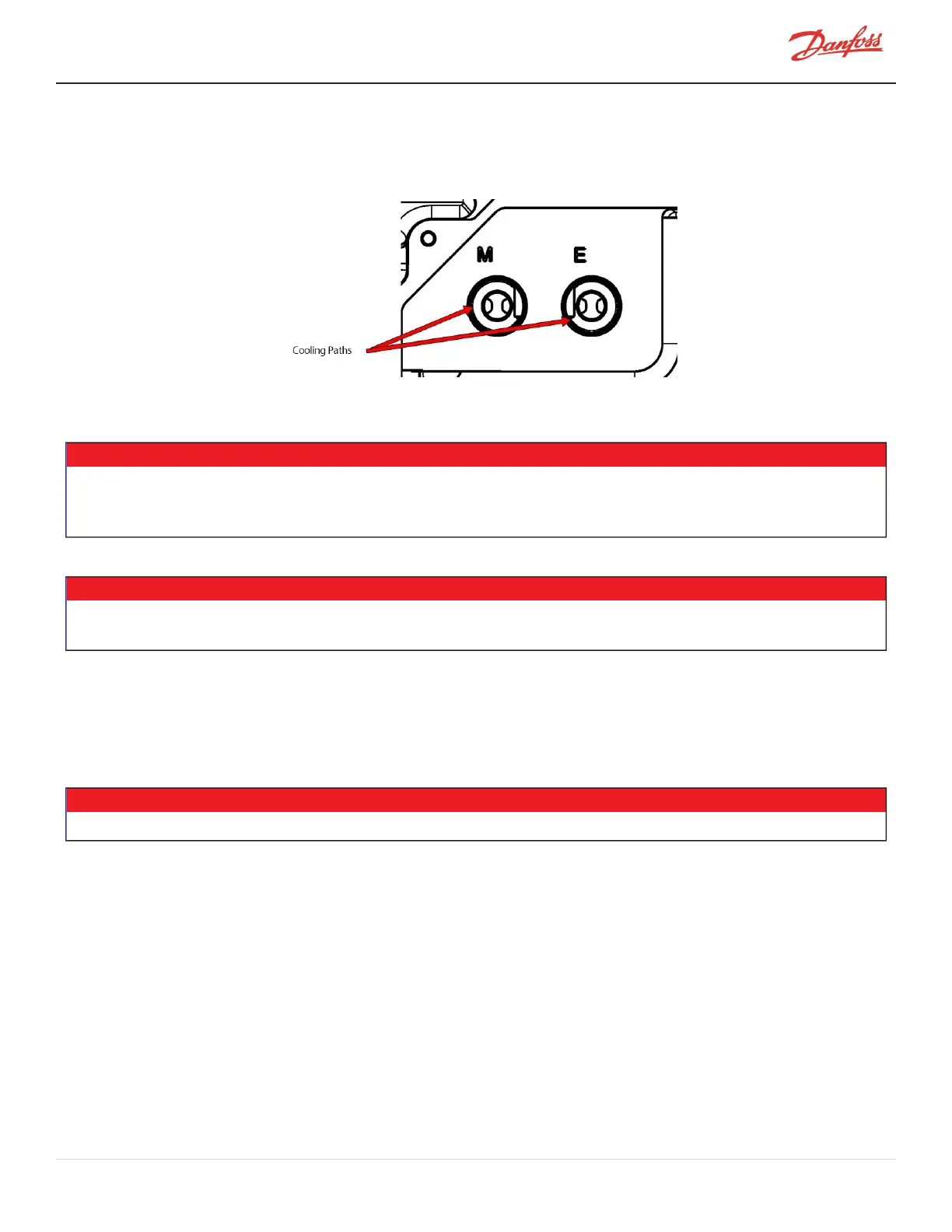

6. Ensurethatthecoolingpathsareclean,asshowninFigure4-34SolenoidCoolingPath-

TTS300/TGS230.

Figure 4-34 Solenoid Cooling Path - TTS300/TGS230

4.6.4 Solenoid and Coil Removal and Installation

NOTE

Oncertaincompressormodels,thesolenoidvalvebodiesmayhavedifferentorificesizesduetothesplit-coolingconfiguration.Itis

importanttonotgettheleftandrightconfusedwhenremovingandinstallingthesesolenoidbodies.RefertoFigure4-29Compressor

CoolingSolenoidCoilsonpage72.

• • • CAUTION • • •

Removalofthecompressorsolenoidswillreleaserefrigerant.Isolationandrecoveryoftherefrigerantmustbeperformedbyaqualified

servicetechnicianadheringtoindustry/ASHRAEstandards.

4.6.4.1 Solenoid and Coil Removal

1. Isolatecompressorpower.

2. Isolatethecompressorandrecovertherefrigerantaccordingtoindustrystandards.RefertoSection3.1

RefrigerantContainmentonpage41.

NOTE

Thereisnoneedtorecovertherefrigerantifonlythesolenoidcoilsarebeingremoved.

3. RemovetheServiceSideCover.RefertoSection4.1.3.1ServiceSideCoverRemovalandInstallationon

page54.

4. DisconnecttheSolenoidCoilJ16connectorfromtheBackplane.RefertoFigure4-31Backplane-J16

Connectoronpage73.

5. Removethesolenoidretainingnutsandthebeveledwashers.

6. Noteandmarkthepositionofeachcoil(leftandright)astheyneedtobeinstalledinthesame

orientationoncetherepairhasbeencompleted.

7. RemovetheSolenoidCoils.RefertoFigure4-35SolenoidComponentRemovalonpage76forthisand

thefollowingfour(4)steps.

8. Beforeremovingeithercoolingvalveassemblyfromthecompressorbody,identifywhichcoolingvalve

assemblygoestotheleftandtotherightpassageastheremaybedifferentorificesizes.Youcanuse

theengravingoneachorificebodytodeterminewhichgoesleftandright.Youshouldalsoverifythat

thenewcoolingvalveassembliesarethesameastheonesbeingremoved.

9. RemovetheSolenoid/TubePlungersusingasix-point13mmdeepsocket.

M-SV-001-EN Rev. H-1/23/2023 Page 75 of 294

Loading...

Loading...