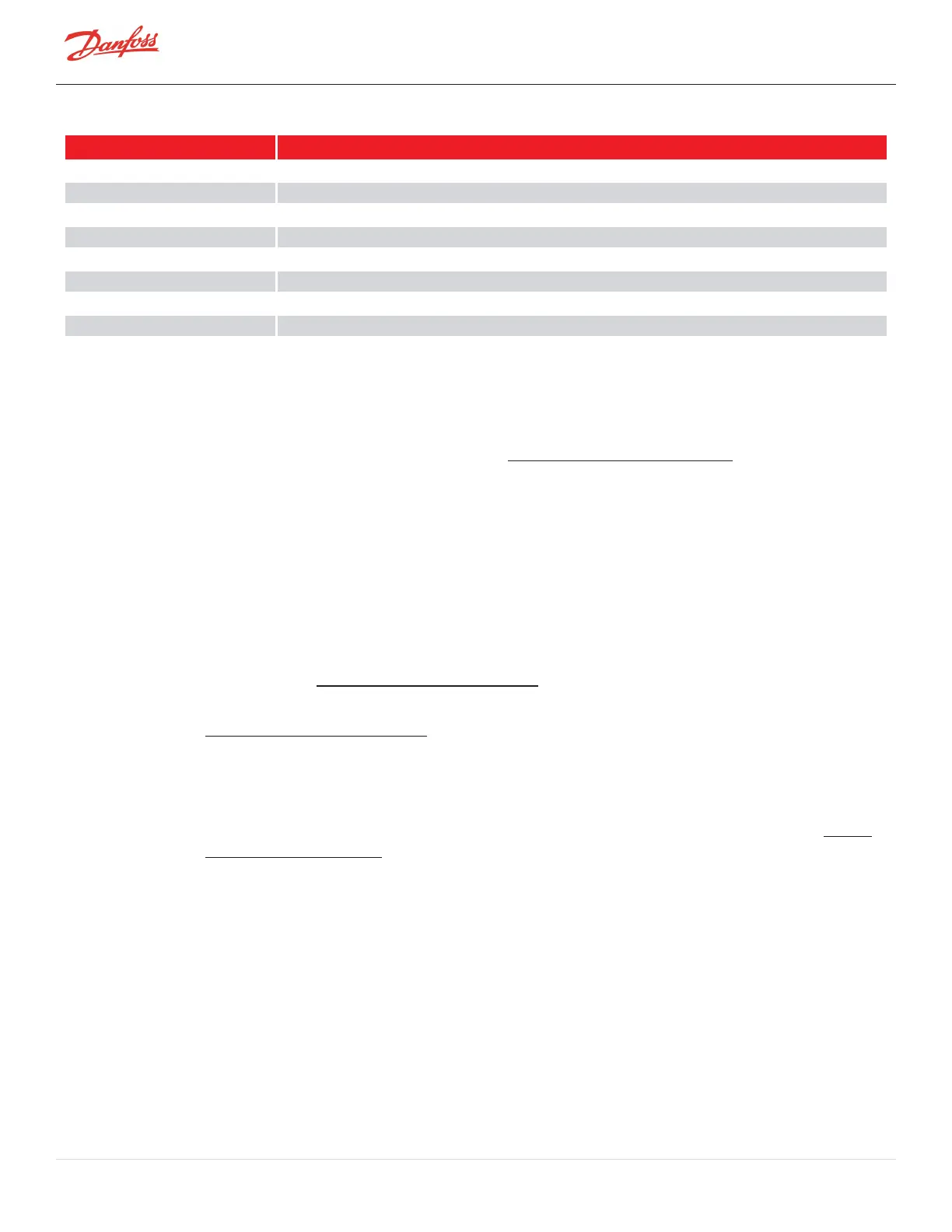

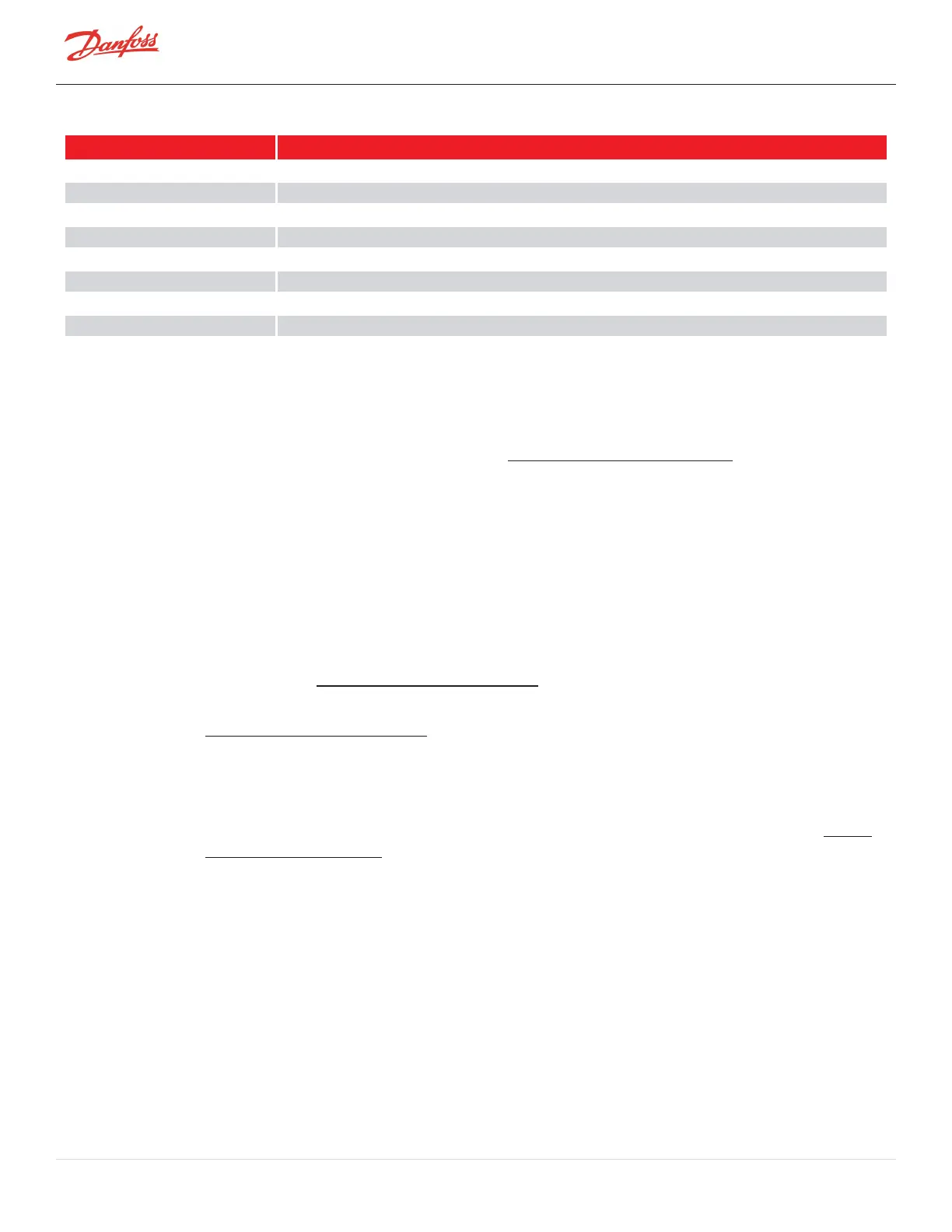

Table 5-5 Bearing Fault Types

Bearing Status Description

StartupCalibrationCheckFault AdiscrepancybetweentheBearingStartupcheckandthestoredcalibrationvalueshasbeendetected.

AxialDisplacementFault AxialOrbithasexceededthelimitlongerthanthemaximumtimeallowable.

AxialOvercurrentFault AxialCurrenthasexceededthelimitlongerthanthemaximumtimeallowable.

FrontRadialDisplacementFault FrontRadialOrbithasexceededthelimitlongerthanthemaximumtimeallowable.

FrontRadialXOvercurrentFault FrontRadialXCurrenthasexceededthelimitlongerthanthemaximumtimeallowable.

FrontRadialYOvercurrentFault FrontRadialYCurrenthasexceededthelimitlongerthanthemaximumtimeallowable.

RearRadialDisplacementFault RearRadialOrbithasexceededthelimitlongerthanthemaximumtimeallowable.

RearRadialXOvercurrentFault RearRadialXCurrenthasexceededthelimitlongerthanthemaximumtimeallowable.

RearRadialYOvercurrentFault RearRadialYCurrenthasexceededthelimitlongerthanthemaximumtimeallowable.

5.2 Troubleshooting with the Service Monitoring Tools Software

TheSMTsoftwarepackagecanbeusedtoviewdetailedcompressorinformationforoperationalstatusindications

andtroubleshootingprocedures.PleaserefertotheServiceMonitoringToolsUserManualforthedetailsonhowto

usetheSMTsoftware.

5.2.1 Compressor Fault Troubleshooting

Whentroubleshootingacompressorfault,detailedanalysisofthisdatashouldbemade(inconjunctionwitha

compressorrecordingfile,ifpossible)todeterminethespecificfaultanddeterminetherootcauseoffault

occurrence.

Downloadingfaultandeventlogseverytimeacompressorisvisitedisusefulfordocumentingcompressor

operationalhistory.

FaultandeventhistorycanbeextractedfromthecompressormemoryintheSMTLoggedEventandFaultViewer

tool.SeethelatestServiceMonitoringToolsUserManualforuserinstructions.

ActivecompressorfaultandalarmmessagescanbeviewedintheSMTActiveAlarm/FaultViewertool.Seethelatest

ServiceMonitoringToolsUserManualforuserinstructions.

CompressorAlarmandFaultsettingscanbefoundintheConfigureAlarms/FaultsmenuoptionoftheActive

Alarm/FaultViewertool.

TheCompressor Data RecordingandPlaybacktoolprovidesamethodofreviewingoperationalconditionswithouta

connectiontothecompressor.Italsocreatesafiletoelectronicallytransmitforpeerreview.SeethelatestService

MonitoringToolsUserManualforuseinstructions.

Thefollowingprincipleisappliedwhenhavingbothafaultand/oranalarmlimitastriggers.RefertoFigure5-1

FaultTriggerMethodsonpage255forexplanationsregardingfaultsandalarmsandthetriggermethod

terminologyisused:

l

Instantfaulttriggering(INS)

l

AscendingFaultTriggering(AFT)

l

DescendingFaultTriggering(DFT)

l

RangeFaultTriggering(RFT)

Page 254 of 294 - M-SV-001-EN Rev. H 1/23/2023

Loading...

Loading...