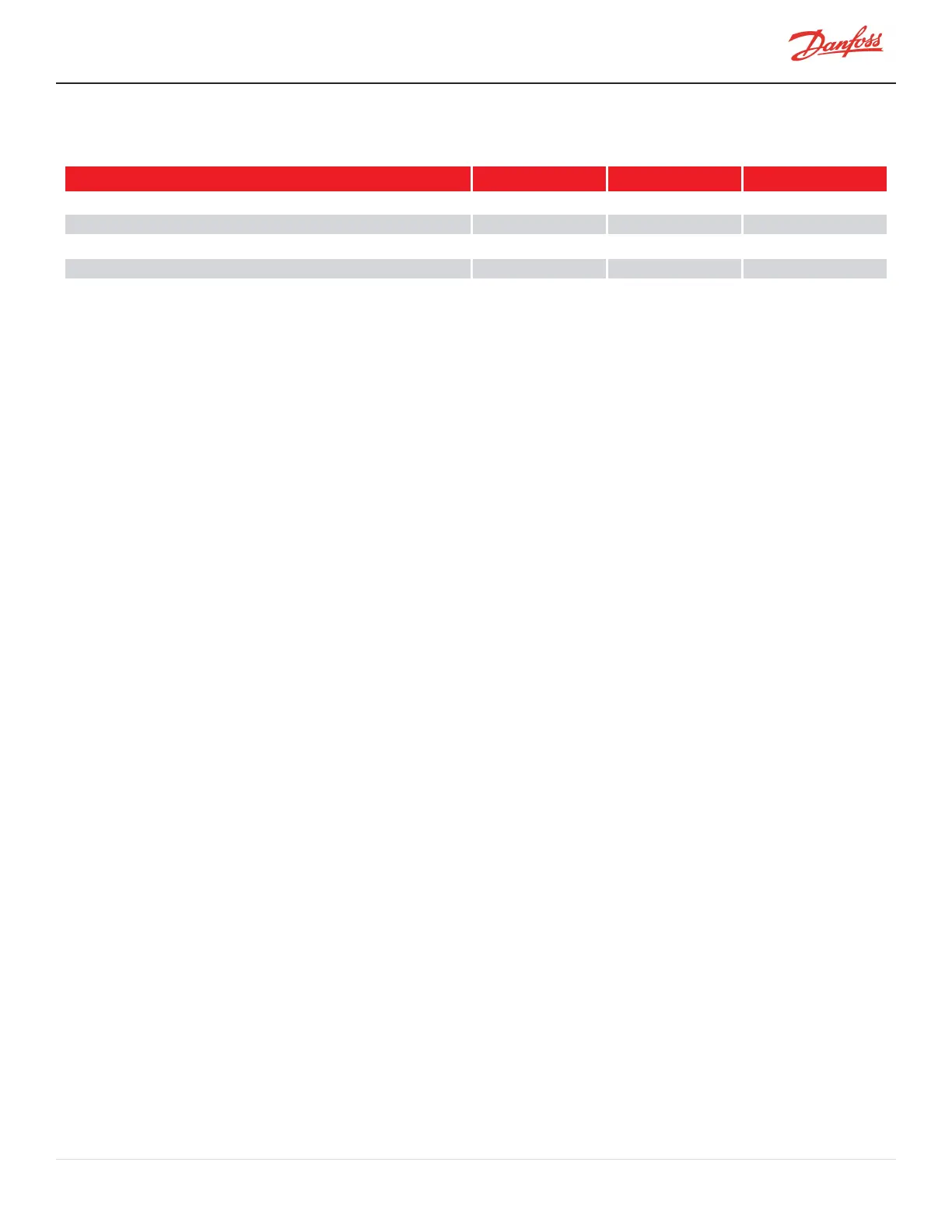

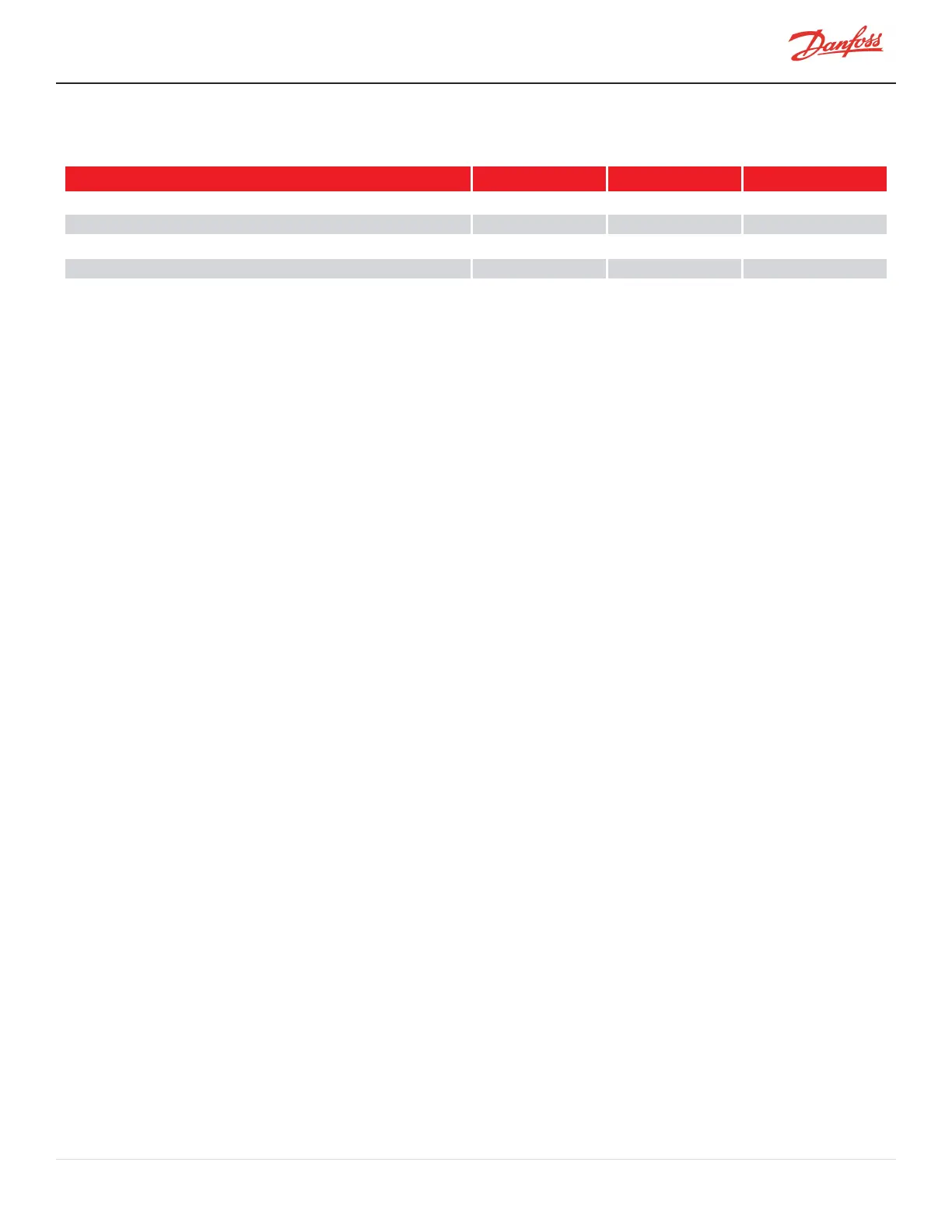

4.9.4 IGV Torque Specifications

Table 4-16 IGV Torque Specifications

Description Nm Ft.Lb. In.Lb.

IGVHousingFastener,M10x40 22 16 195

IGVFeedthroughFastener,M5x16 5 - 44

IGVMotorSetscrew,M5x8 5 - 44

IGVThroatFastener,M6x55 5 - 44

LockingCollar 5 - 44

M-SV-001-EN Rev. H-1/23/2023 Page 95 of 294

Loading...

Loading...