Adjustments and Maintenance

2-12

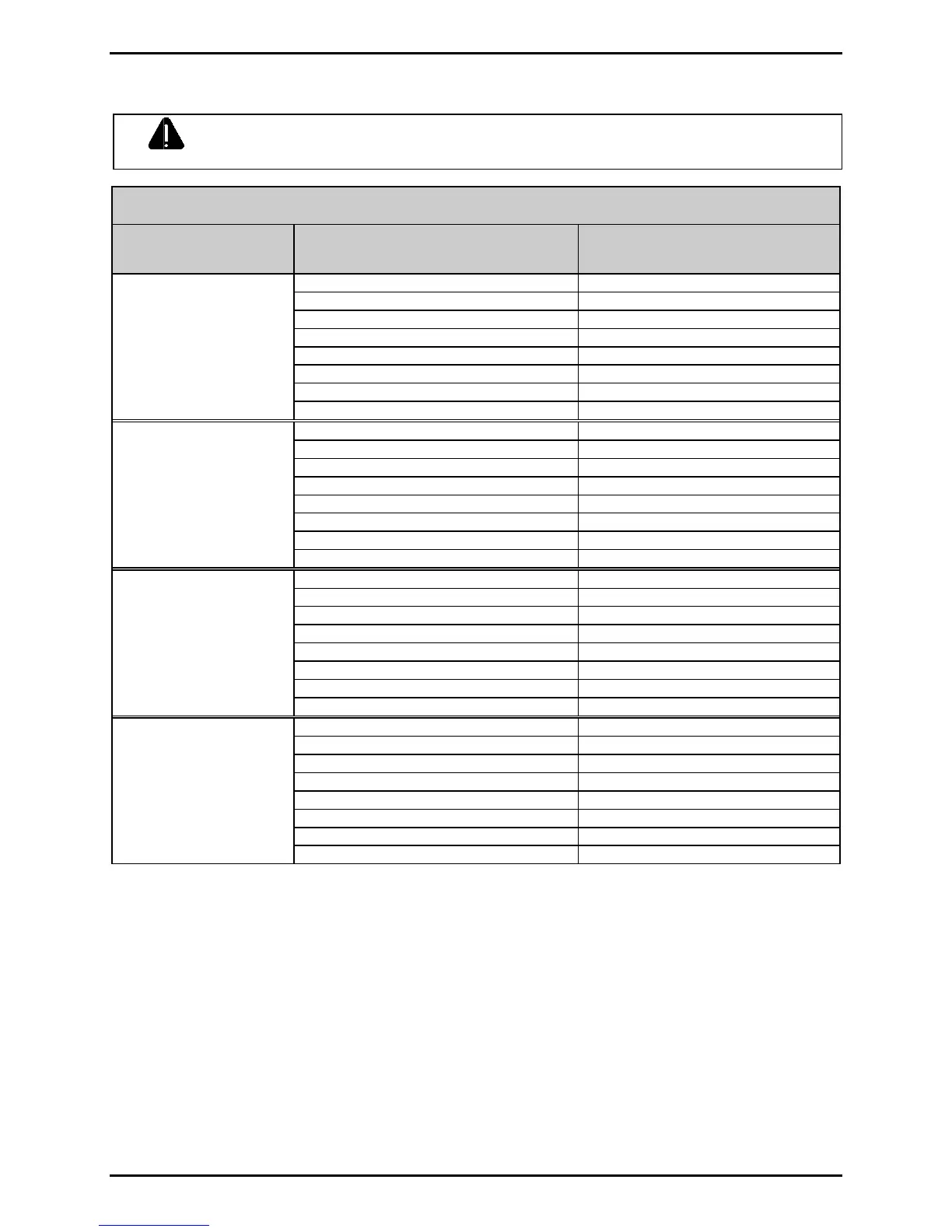

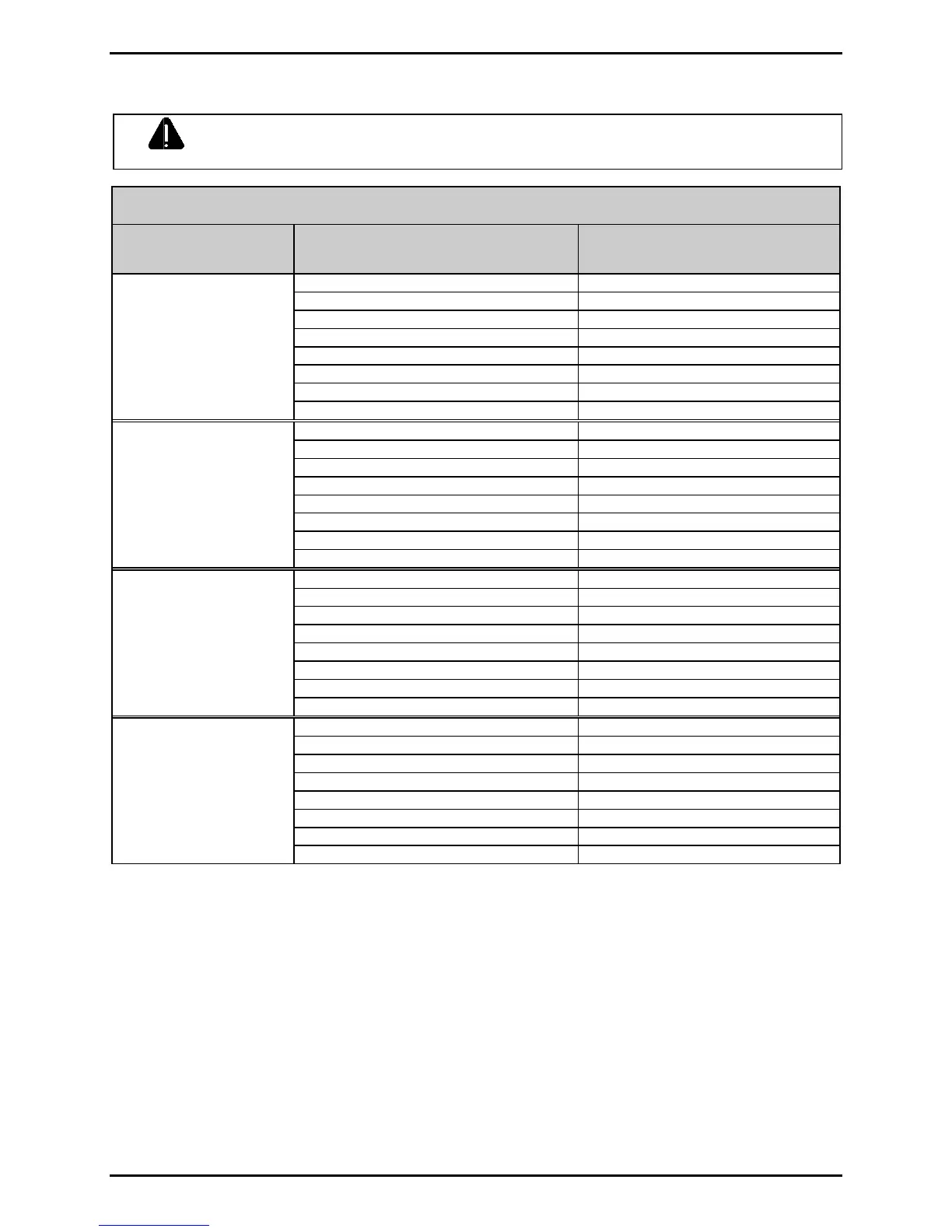

WARNING

NEVER exceed the recommended Printhead Voltage; permanent damage or

shortened service life can result.

Printhead Voltage Adjustment Table

Printer

Model

Printhead Resistance

(ohms)

Printhead Voltage

(+/- 0.1 Volt DC)

561 – 586 22.4

587 – 611 22.9

612 – 635 23.3

636 – 660 23.8

661 – 685 24.2

686 – 710 24.7

711 – 734 25.1

I4206,

I4208,

I4210,

&

I4212

735 – 759 25.5

947 – 989 22.4

990 – 1030 22.9

1031 – 1072 23.4

1073 – 1114 23.8

1115 – 1156 24.2

1157 – 1197 24.7

1198 – 1239 25.1

I4308

1240 – 1281 25.5

935 – 976 22.4

977 – 1018 22.9

1019 – 1059 23.3

1060 – 1100 23.8

1101 – 1141 24.2

1142 – 1183 24.7

1184 – 1224 25.1

I4406

1225 – 1265 25.5

1530 – 1598 22.4

1599 – 1665 22.9

1666 – 1733 23.4

1734 – 1800 23.8

1801 – 1868 24.2

1869 – 1935 24.7

1936 – 2003 25.1

I4604

2004 – 2070 25.5

2.3 Ribbon Path Alignment

If irregular voids extend intermittently, diagonally through an image printed with ribbon, the cause

may be due to ribbon overlap (wrinkling). However, other factors can be involved. Begin

troubleshooting by verifying correct adjustment of the Leveling Cam (Section 2.2.1), Printhead

Pressure (Section 2.2.2), and Burn Line (Section 2.2.3). Also, examine the platen for wear, debris

buildup, and excessive lateral movement. If all of these adjustments and components are in good

order, then perform a Ribbon Path Alignment as follows:

Loading...

Loading...