3.4.5 Install PE Cable

- The ground connection in the first step is recommended because the earthed

outer casing of the inverter can protect the persons against electrical shocks.

CAUTION !

The inverter provides internal and external PE terminal for grounding. The ground

connection can be installed on the internal, external or both with the proper

sizing of the cable which is met system safety requirement and refer to 3.4.4.

If single-core cable is used, it should meet the requirement from 3.4.4 and the

installation is shown as following:

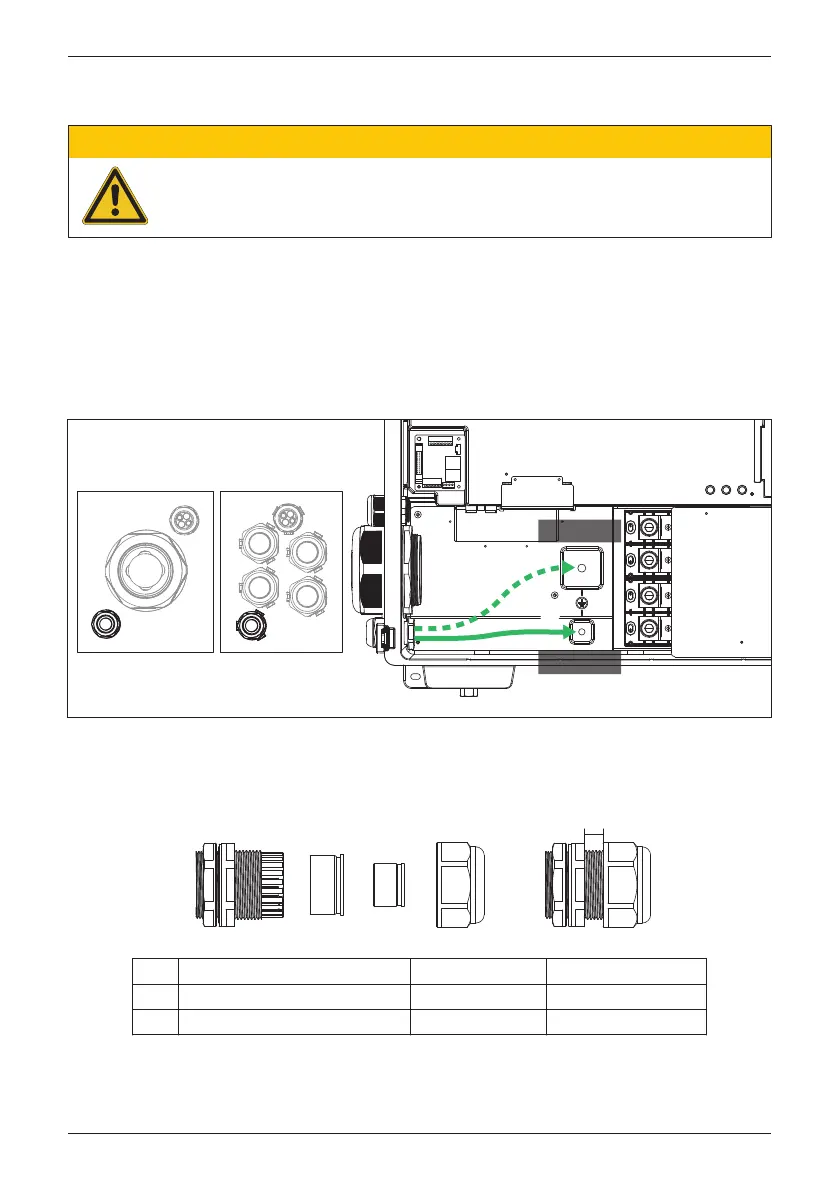

(1) According to Table 3-4 to choose proper PE single-core cable size with proper

inner rubber of cable gland and pass PE cable through inner rubber to the

internal grounding terminal of inverter.

(2) According to the figures to install PE single-core cable and use M8 spanner

to tighten the nut with 14.7 N-m torque.

(3) Fasten the protective earth cable gland to meet requirement for waterproof.

Internal PE terminal

Figure 3-12: Location for internal PE terminal - single core cable

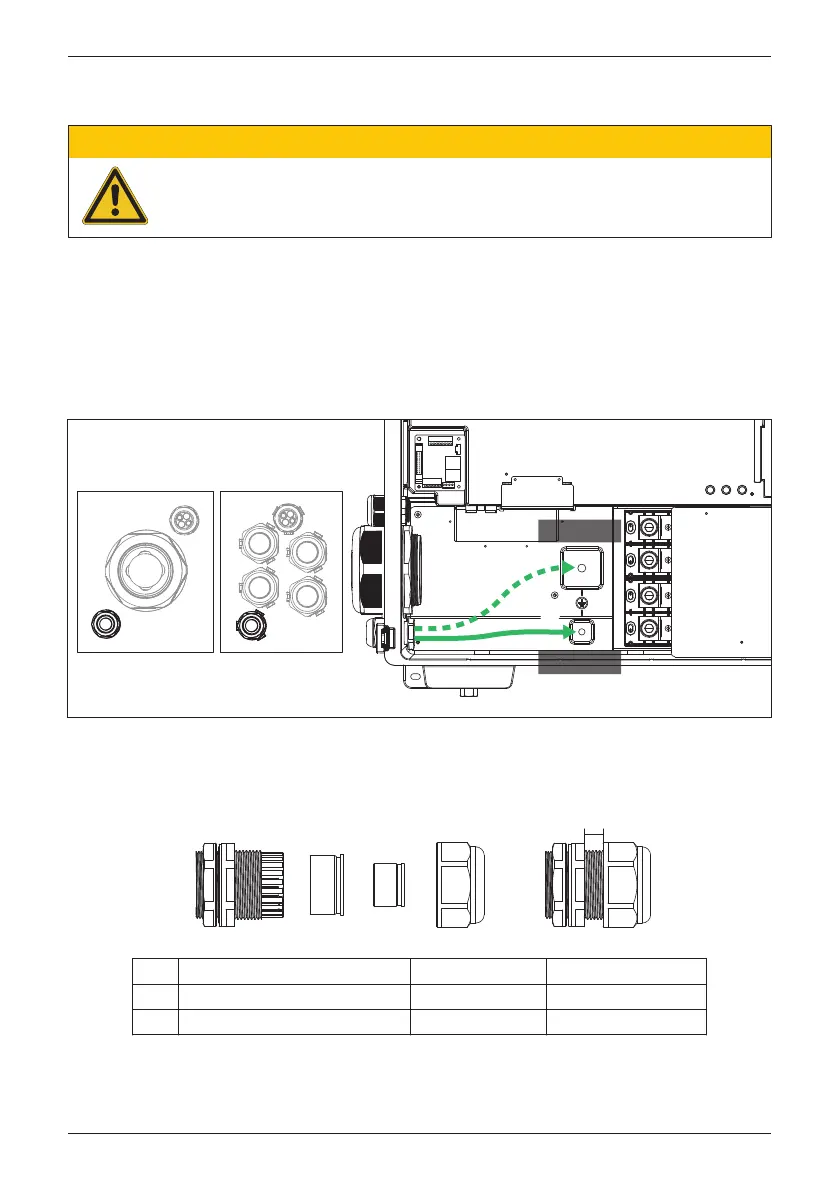

PE

M100A_280 M110A_283

M100A_283

PE

D1 D2

D1

D2

16.0 - 23.0 mm

10.0 -16.0 mm

Cable diameter range

Torque

3.5-5.2

N•m

3.5 N•m

Dimension of P

P

1.5-5.0 mm

1.5-5.0 mm

Table 3-4: Specification of PE gland

PE

PE

or

24.5 N‧m24.5 N‧m

14.7 N‧m14.7 N‧m

31

Installation

Loading...

Loading...