Maintenance – Planned maintenance

10-03-2022 4812331840EN 95

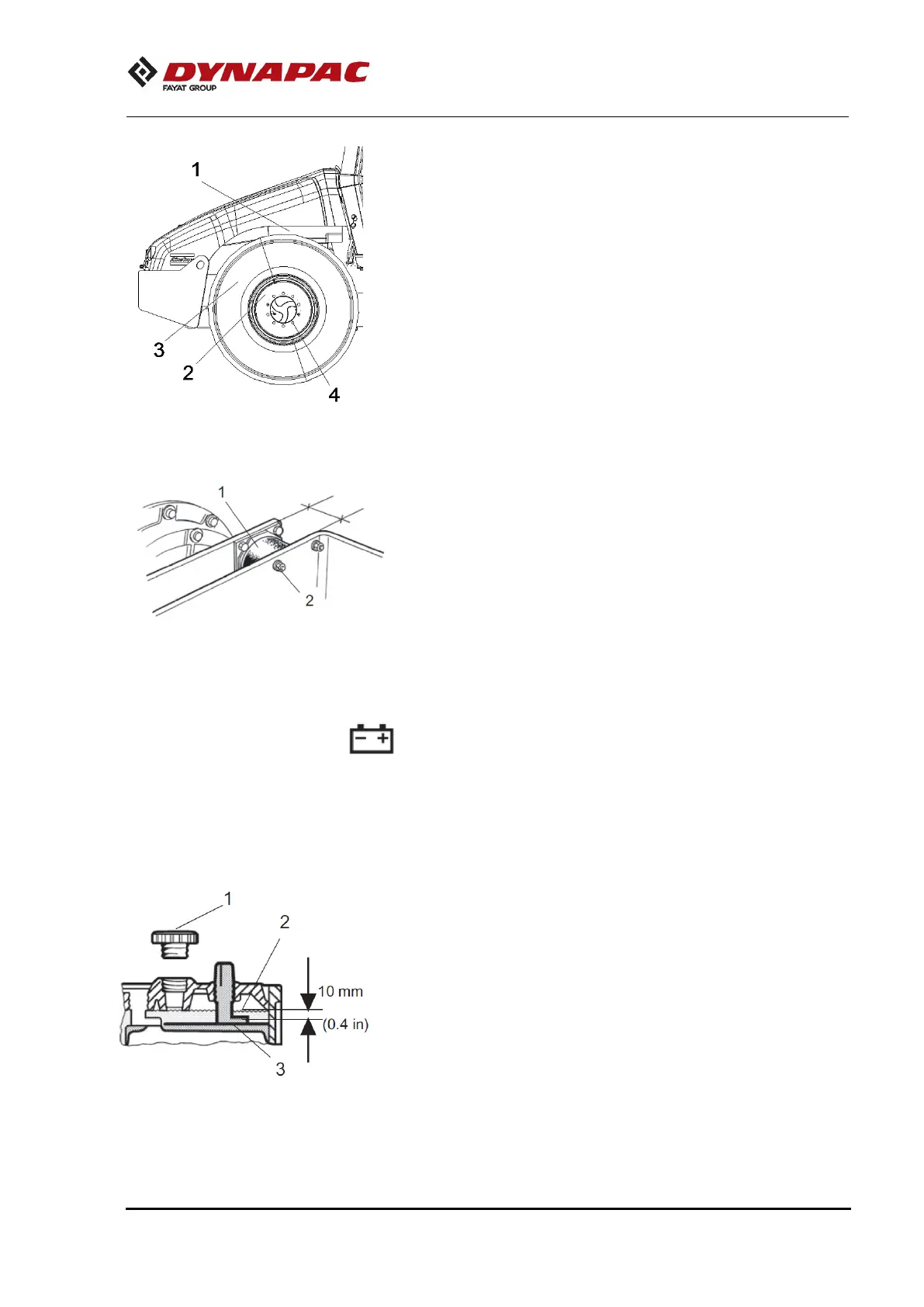

Bolted joints – Checking tightening

Steering pump for the diesel engine (1) 55 Nm, lightly oiled.

Rear axle suspension (2), 330 Nm (243 ft/lbf) oiled.

Engine shock mount (3). Check that all the M12 bolts (20

pieces) are tightened with 70 Nm and lightly oiled.

Wheel nuts (4). Check that all nuts are tightened, 630 Nm, and

oiled.

(The above applies to new or replaced components only).

Rubber elements and fastening screws

Check all rubber elements (1), replace all of the elements if

more than 25% of them on one side of the roller are cracked

deeper than 10-15 mm.

Use the blade of a knife or pointed object to help you check.

Make sure as well that the fastening screws (2) are tightened.

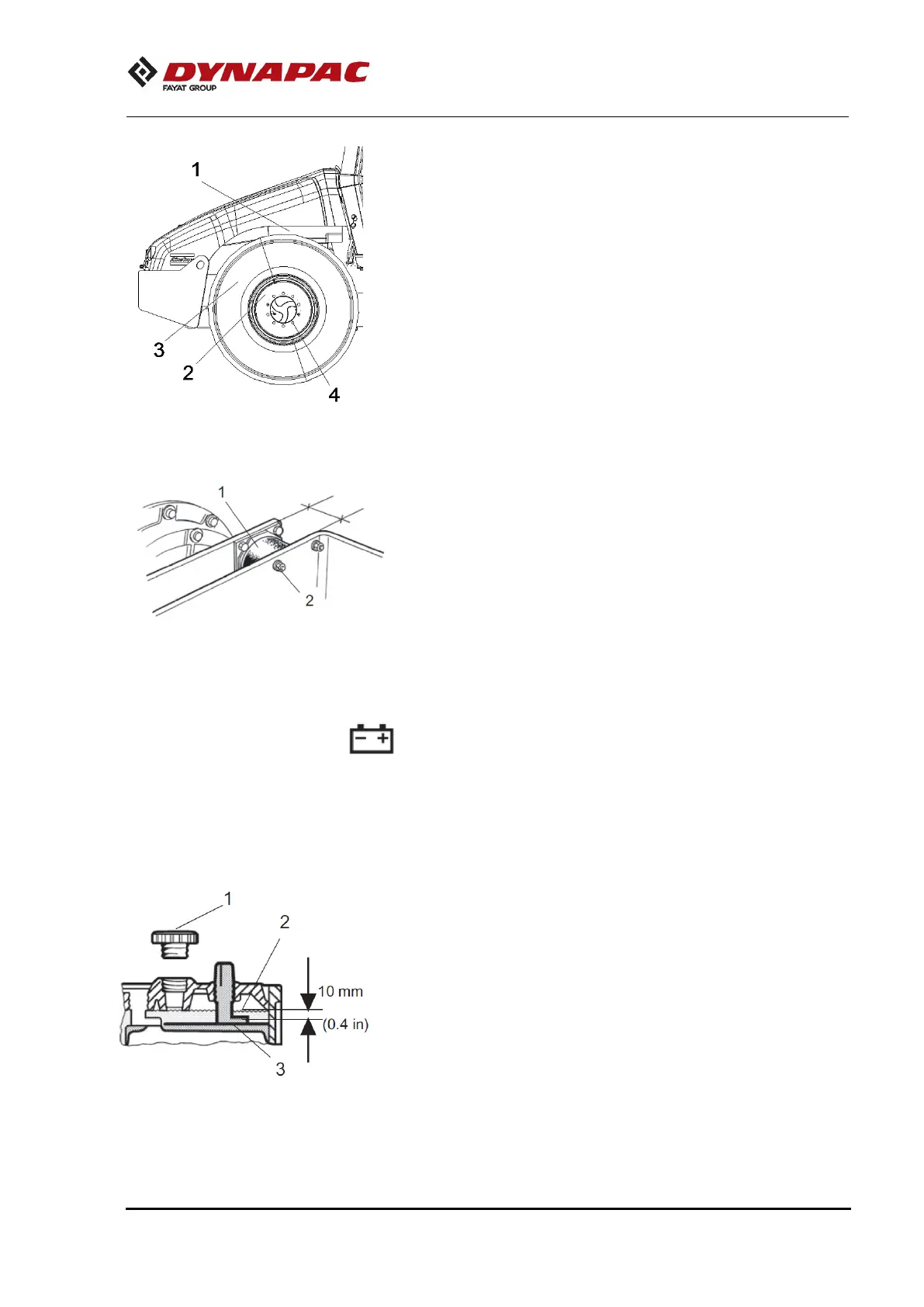

Check – Battery cell

Take off the cap (1) and make sure that electrolyte level (2) is

about 10 mm above the plates. If the level is lower, top up to

the correct level with distilled water.

If the ambient temperature is below freezing, run the engine for

a while after topping up with distilled water. Otherwise the

electrolyte might freeze.

Make sure that ventilation openings of the element covers are

not clogged, then put the cover back on.

The cable terminals must be properly tightened and clean.

Clean corroded cable shoes and grease them with acid-free

Vaseline.

Observe care when using a high-pressure jet and do not place

the nozzle too close to the radiator.

Always disconnect the negative cable first when disconnecting

the battery. When connecting the battery, always connect the

positive cable first.

Fig. Drum, vibration side

1. Rubber element

2. Attachment screws

Fig. Electrolyte level in battery:

1. Cap;

2. Electrolyte level;

3. Plate.

Fig. Right side of machine

1. Steering Pump

2. Rear Axle

3. Engine shock mount

1. Wheel nut

Loading...

Loading...