3

Instruction Leaflet IL 29C101H

Effective January 2011

Installation Instructions for EHD, EDB, EDS, ED, EDH, EDC, FDB, FD,

HFD, FDC, HFDDC Circuit Breakers and Molded Case Switches

EATON CORPORATION www.eaton.com

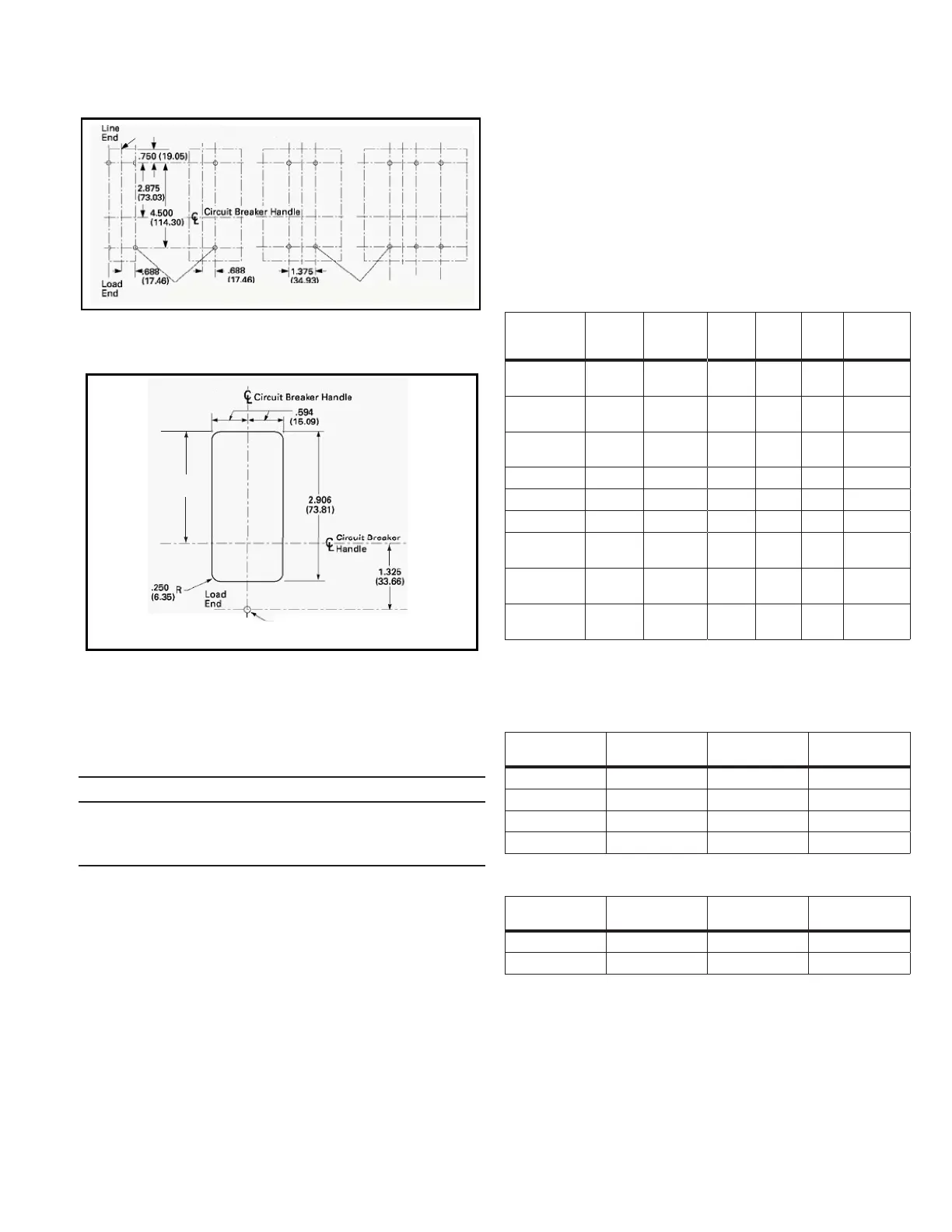

Figure 2. Circuit Breaker Mounting Bolt Drilling Plans

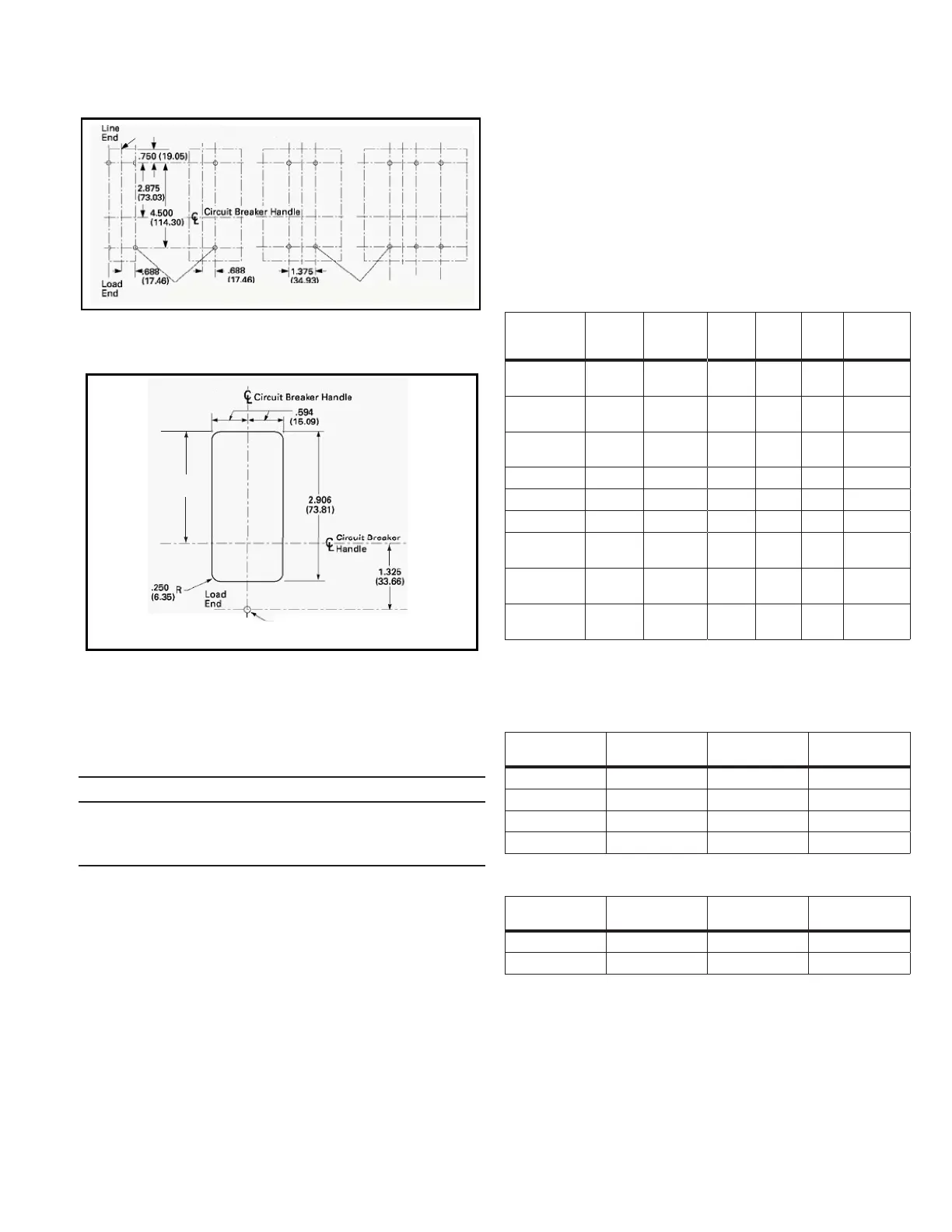

Figure 3. Circuit Breaker Esutcheon Dimensions

2-4. If an optional terminal end cover is to be installed with the

circuit breaker (usually line end only), it must be positioned before

cable is connected to terminals.

DCAUTION

WHEN ALUMINUM CONDUCTORS ARE USED, THE APPLICATION OF

A SUITABLE JOINT COMPOUND IS RECOMMENDED TO REDUCE THE

POSSIBILITY OF TERMINAL OVERHEATING. TERMINAL OVERHEATING CAN

CAUSE NUISANCE TRIPPING AND DAMAGE TO THE CIRCUIT BREAKER.

2-5. After mounting the circuit breaker, line and load terminals and

accessory leads should be connected. (See accessory schematic

diagram on side of circuit breaker.)

ote:N If terminal shield or interphase barriers are to be installed on the circuit

breaker, install them after the terminals are connected.

3

Poles

(M4

x

.07)

Poles

3

Poles

2

Poles

1

Pole

.164-32 Tap Holes

(M4 x .07)

.164-32 Tap Holes

(M4 x .07)

4

2913

I

.188 (4.78 mm) Dia. Hole for

Access to Push-to-Trip

Line

End

2.313

(58.75)

2-6. If required, install terminal shield on circuit breaker cover with

mounting screws provided.

2-7. If required, install an interphase barrier by sliding barrier into

dovetail grooves between terminals.

2-8. After the circuit breaker is installed, check all mounting hard-

ware and terminal connecting hardware for correct torque loading.

Torque values for line/load terminals are given in Tables 1, 2, and 3

and on the circuit breaker nameplate.

ote:N See Section 5 for additional details for HFDDC.

Table 1. Terminal Types

Terminal

Catalog

Number

Terminal

Body

Material

Screw

Head Type

AWG

Wire

Range

Metric

Wire

Range

Wire

Type

Torque

Value, Lb.

in.(N.m)

3TA225FD

Aluminum 3/16 Socket

Hex

#4-4/0 25-95 Cu/Al 120 (13.6)

3TA225FDM

Aluminum 5mm Socket

Hex

#4-4/0 25-95 Cu/Al 120 (13.6)

3TA225FDK

b

Aluminum 5/16 Socket

Hex

#6-300 16-150 Cu/Al 275 (31)

3TA100FD

Aluminum Slotted #14-1/0 2.5-5.0 Cu/Al See Table 2

3TA50FB

Aluminum Slotted #14-#4 2.5-16 Cu/Al See Table 2

3T100FB

Steel Slotted #14-1/0 2.5-50 Cu/Al See Table 2

3T150FB

Stainless

Steel

Slotted #4-4/0 25-95 Cu

Only

See Table 2

3TA150F3K Aluminum 5/32 Socket

Hex

#14-2 2.5-25 Cu/Al 70 (7.9)

3TA150F6K Aluminum 3/32 Socket

Hex

#14-6 2.5-10 Cu/Al 25 (2.8)

Note: Terminal wire connectors are UL listed for standard wire sizes as defined in UL 486A

and UL486B.

Package of Three

b

Individual terminal identified as TA225FD1

Table 2. Terminal Torque Values for Slotted Head

Metric Wire

Range

Torque Value N.m AWG Wire Range Torque Value,

Lb.-In.

2.5-6 3.96 #14-#10 35

10 4.52 #8 40

16-25 5.09 #6-#4 45

35-95 5.65 #3-4/0 50

Table 3. Bolted Connections (Keeper Nut or End Cap)

Termination

Catalog Number

Screw Head Type Nut Thread Size Torque Value Lb.

In. (N.m)

KPR1A/KPR1AM Upper Supplied 10-32/M5 35 (4.0)

KPEKxxx Slotted 10-32/M5 35 (4.0)

Loading...

Loading...