STP-iXR1606 Turbomolecular Pump

MT-79E-001-D

Page 152

MAINTENANCE AND INSPECTION

8

8.4.3 Recommended maintenance intervals for main parts

Internal components of the STP pump will be damaged from gas load, heat, and corrosion when

used long-term. Deterioration or abrasion of the internal parts of the STP pump will cause

unexpected failures. When overhauling the STP pump, replacement of main parts are recommended.

Refer to the following list as recommended maintenance intervals for main parts.

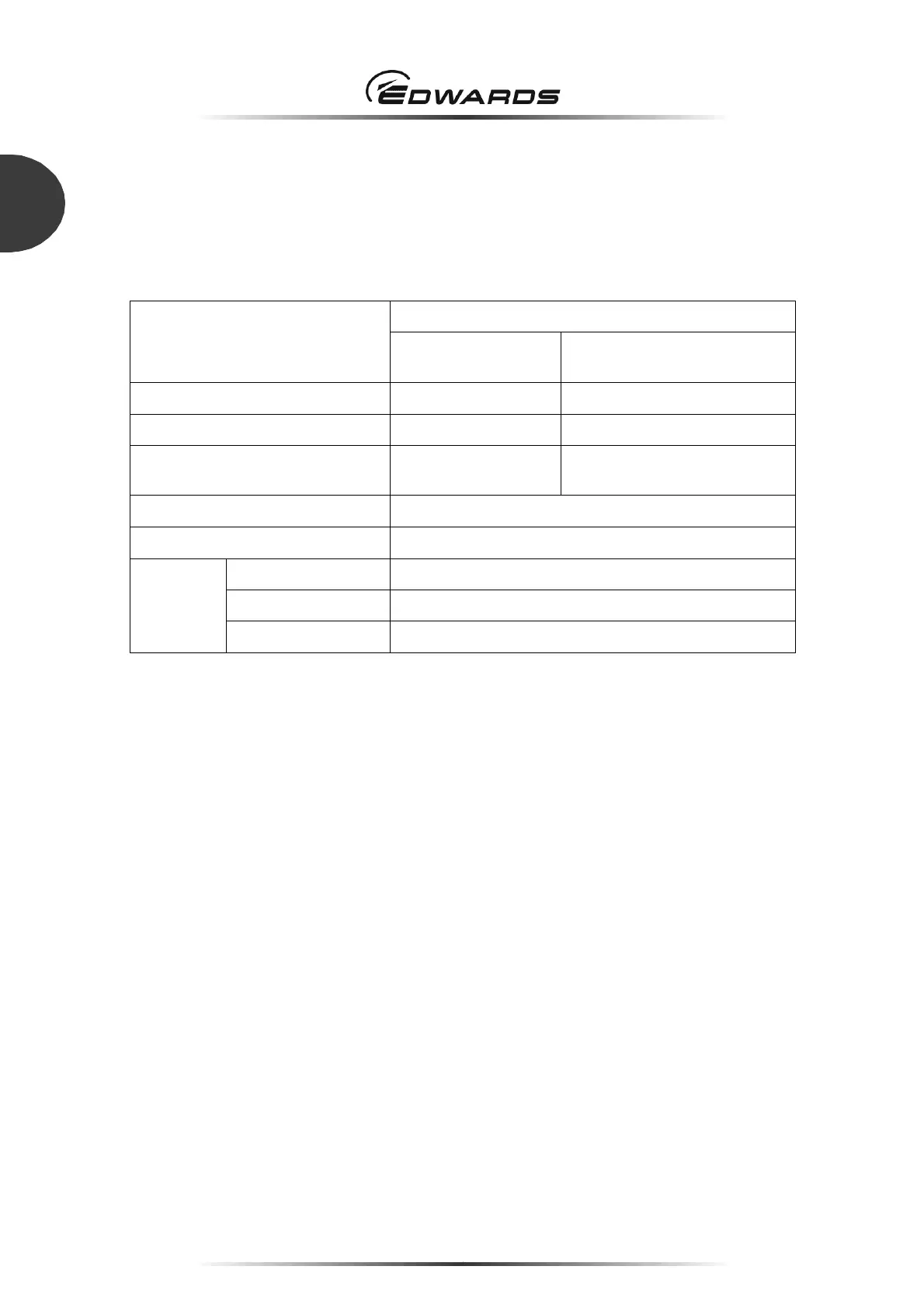

Part name

Recommended maintenance intervals

Corrosive gas

Inert gas or

vacuum pumping only

Rotor blades 3 years 5 years

Rotor shaft 3 years 5 years

Motor, sensor, electromagnet,

connector

5 years 7 years

Air-cooling fan 5 years

PCBA in the control unit 7 years

Accessories TMS valve 3 years

TMS heater 3 years

Connection cable 5 years

*1: Maintenance intervals of any parts may be shortened depending on the condition of use.

The costs of replacing parts that need to be replaced when deterioration or abrasion is observed will

be at the customers charge, even though a period is not exceeding the recommended maintenance

intervals.

When overhaul of the STP pump is needed, contact Service office.

Loading...

Loading...