13

Reference Manual

00809-0100-4840, Rev CB

Section 3: Installation

February 2015

Installation

Installing in a tank with a nozzle or stand-off

Installation instructions

1. Use PTFE tape on the screw thread of the transmitter (Figure 3-4 on page 13).

2. If the tank has a flanged nozzle or stand-off:

a. Attach the transmitter to a non-metal instrument flange using the threaded

connection. Tighten to a torque of 1.5 lb-ft (2 N-m) using the transmitter’s hexagon.

b. The instrument (accessory) flanges supplied by Emerson Process Management are

manufactured from PVC and are a full face design. Care must be taken when installing

to a raised face mating flange on the tank or vessel to prevent distortion of the PVC

flange by over-tightening the bolts.

c. Ensure the gasket is sitting correctly on the nozzle/tank flange.

d. Lower the assembled transmitter and instrument flange onto the tank flange, and

secure with appropriate bolting to a suitable torque for the flanges.

If mating to a raised face flange (RF) on the tank nozzle or stand-off, tighten to a

maximum torque of 10 lb-ft (13.6 N-m).

3. If the tank has a threaded nozzle or stand-off:

a. Attach the transmitter to the nozzle/stand-off using the threaded connection.

b. Tighten to a torque of 1.5 lb-ft (2 N-m) using the transmitter’s hexagon.

Note

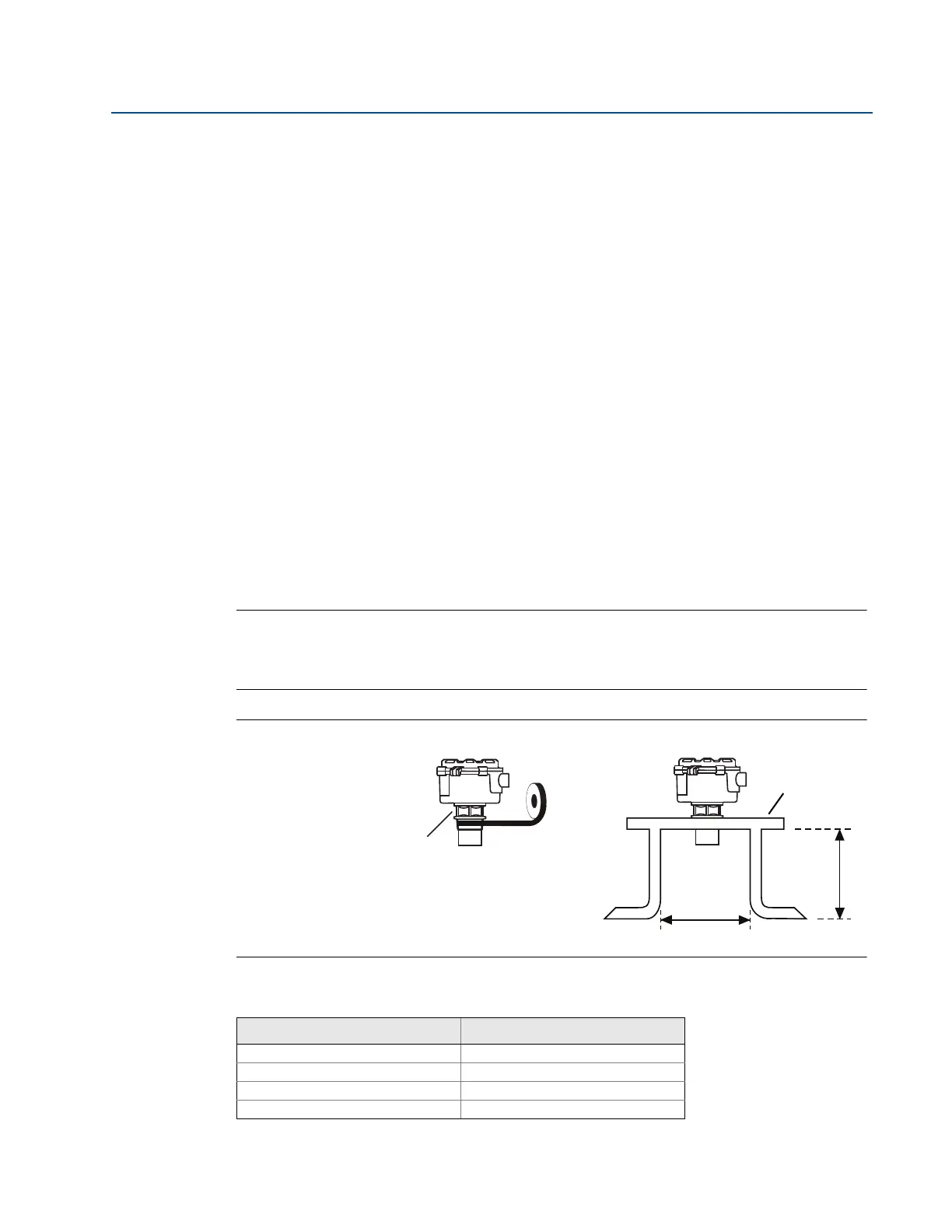

If the transmitter face does not protrude into the vessel, note the dimensions in Tabl e 3-1 for

Figure 3-4, and always ensure that the nozzle/vessel weld is smooth and free from internal weld

beads or other projections.

Figure 3-4. Mounting the Transmitter using a Nozzle/Stand-off

Table 3-1. Nozzle diameter size (D) and maximum length (L)

Nozzle Diameter Size (D) Maximum Nozzle Length (L)

DN50 (2 in.) 4 in. (100 mm)

DN80 (3 in.) 6.3 in. (160 mm)

DN100 (4 in.) 6.3 in. (160 mm)

DN125 (5 in.) 11.8 in. (300 mm)

PTFE

L

D

Tighten to a torque of 1.5 lbf.ft

(2 Nm) using the hexagon. Do

not use the housing to tighten

Use non-metallic

fitting / flange

Loading...

Loading...