148 Troubleshooting, Diagnoses and Maintenance CG Drives & Automation 01-7318-01r1

12.2 Trip conditions, causes and

remedial action

The table later on in this section must be seen as a basic aid

to find the cause of a system failure and to how to solve any

problems that arise. An AC drive is mostly just a small part

of a complete AC drive system. Sometimes it is difficult to

determine the cause of the failure, although the motor

inverter gives a certain trip message it is not always easy to

find the right cause of the failure. Good knowledge of the

complete drive system is therefore necessary. Contact your

supplier if you have any questions.

The AFR/AFG/VSI is designed in such a way that it tries to

avoid trips by limiting torque, overvolt etc.

Failures occurring during commissioning or shortly after

commissioning are most likely to be caused by incorrect

settings or even bad connections.

Failures or problems occurring after a reasonable period of

failure-free operation can be caused by changes in the system

or in its environment (e.g. wear).

Failures that occur regularly for no obvious reasons are

generally caused by Electro-Magnetic Interference. Be sure

that the installation fulfils the demands for installation

stipulated in the EMC directives. See chapter 8. page 51.

Sometimes the so-called “Trial and error” method is a

quicker way to determine the cause of the failure. This can

be done at any level, from changing settings and functions to

disconnecting single control cables or replacing entire drives.

The Trip Log can be useful for determining whether certain

trips occur at certain moments. The Trip Log also records

the time of the trip in relation to the run time counter.

12.2.1 Technically qualified personnel

Installation, commissioning, demounting, making

measurements, etc., of or at the motor inverter may only be

carried out by personnel technically qualified for the task.

12.2.2 Opening the FDUL/VFXR/

FDUG/VFXG

The connections for the control signals and the switches are

isolated from the mains voltage. Always take adequate

precautions before opening the AFR/AFG or VSI.

12.2.3 Precautions to take with a

connected motor

If work must be carried out on a connected motor or on the

driven machine, the mains voltage must always first be

disconnected from the AFR/AFG and VSI. Wait at least 5

minutes before continuing.

12.2.4 Autoreset Trip

If the maximum number of Trips during Autoreset has been

reached, the trip message hour counter is marked with an

“A”.

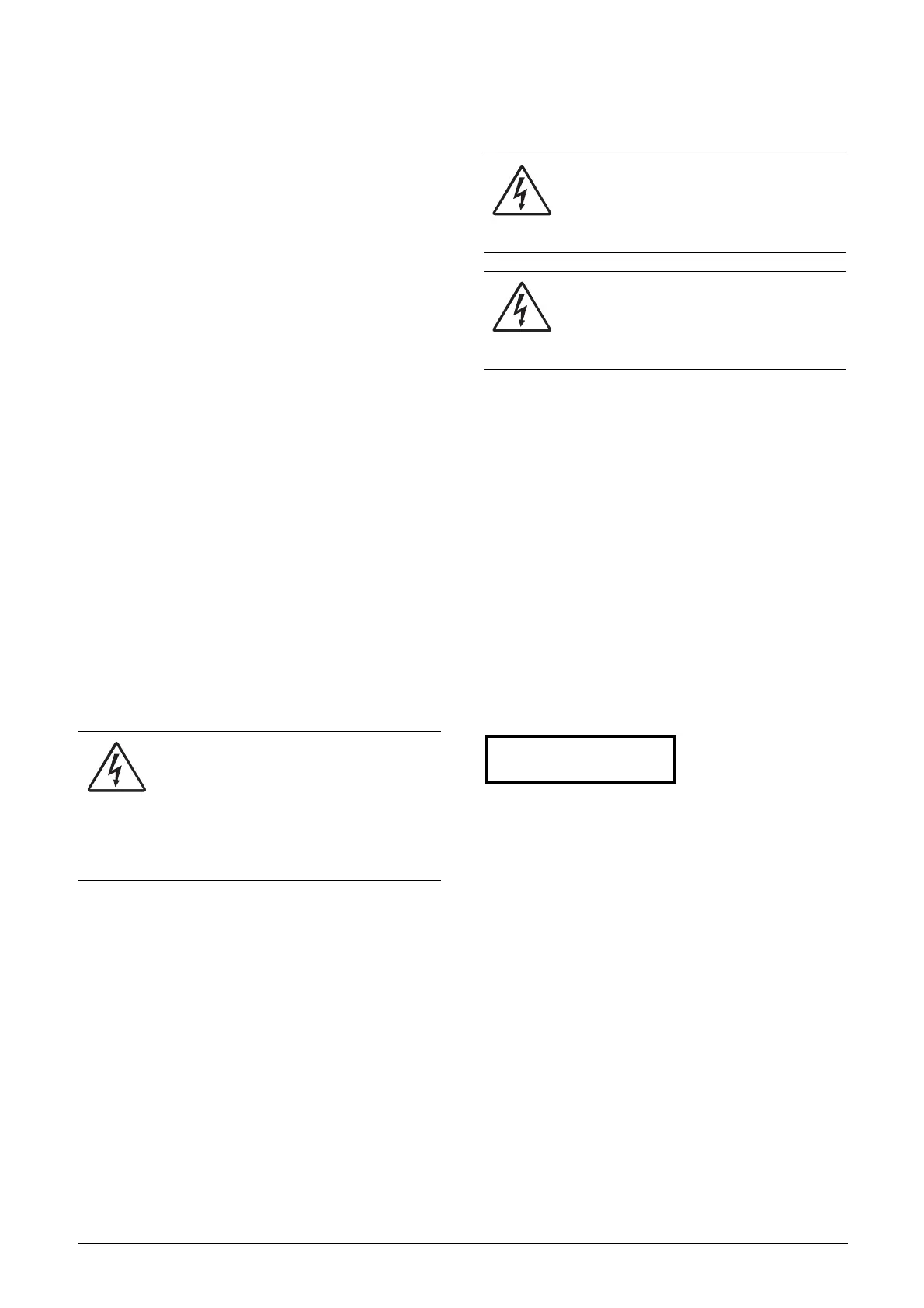

Fig. 94 Autoreset trip

Fig. 94 shows the 3rd trip memory menu [830]:

Overvoltage G trip after the maximum Autoreset attempts

took place after 345 hours, 45 minutes and 12 seconds of

run time.

WARNING!

If it is necessary to open the AFR/AFG or VSI

or any part of the system (motor cable

housing, conduits, electrical panels,

cabinets, etc.) to inspect or take measure-ments as

suggested in this instruction manual, it is absolutely

necessary to read and follow the safety instructions in

the manual.

WARNING!

Always switch the mains voltage off if it is

necessary to open the AFR/AFG or VSI and

wait at least 7 minutes to allow the

capacitors to discharge.

WARNING!

In case of malfunctioning always check the

DC-link voltage, or wait one hour after the

mains voltage has been switched off, before

dismantling the AFR/AFG or VSI for repair.

830 OVERVOLT G

Trp A 345:45:12

Loading...

Loading...