16 Installation Emotron AB 01-4429-01r2

3.2.2 Motor cables

To comply with the EMC emission standards the variable

speed drive is provided with a RFI mains filter. The motor

cables must also be screened and connected on both sides. In

this way a so-called “Faraday cage” is created around the

VSD, motor cables and motor. The RFI currents are now

fed back to their source (the IGBTs) so the system stays

within the emission levels.

Recommendations for selecting motor

cables

• Use screened cables according to specification in table 7.

Use symmetrical shielded cable; three phase conductors

and a concentric or otherwise symmetrically constructed

PE conductor, and a shield.

• When the conductivity of the cable PE conductor is

<50% of the conductivity of the phase conductor, a sep-

arate PE conductor is required.

• Use heat-resistant cables, +60°C or higher.

• Dimension the cables and fuses in accordance with the

nominal output current of the motor. See table 49, page

167.

• Keep the motor cable between VSD and motor as short

as possible.

• The screening must be connected with a large contact

surface of preferable 360

° and always at both ends, to

the motor housing and the VSD housing. When painted

mounting plates are used, do not be afraid to scrape

away the paint to obtain as large contact surface as possi-

ble at all mounting points for items such as saddles and

the bare cable screening. Relying just on the connection

made by the screw thread is not sufficient.

• The litz ground connection, see fig. 24, is only necessary

if the mounting plate is painted. All the variable speed

drives have an unpainted back side and are therefore

suitable for mounting on an unpainted mounting plate.

Connect the motor cables according to U - U, V - V and

W - W, see Fig. 20 and Fig. 21.

Switches between the motor and the

VSD

If the motor cables are to be interrupted by maintenance

switches, output coils, etc., it is necessary that the screening

is continued by using metal housing, metal mounting plates,

etc. as shown in the Fig. 23.

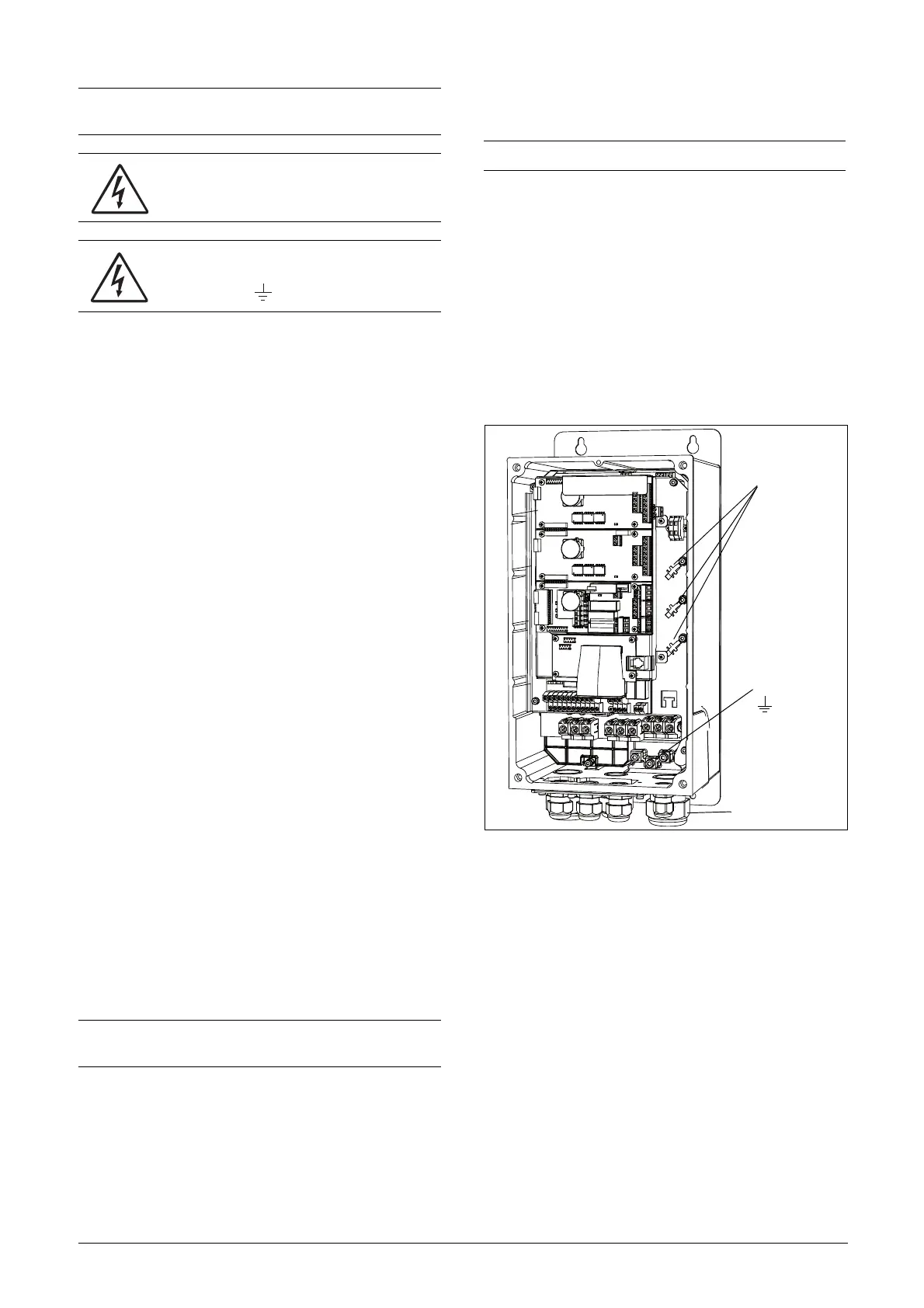

Fig. 24 shows an example when there is no metal mounting

plate used (e.g. if IP54 variable speed drives are used). It is

important to keep the “circuit” closed, by using metal hous-

ing and cable glands.

Fig. 22 Screen connection of cables.

Pay special attention to the following points:

• If paint must be removed, steps must be taken to prevent

subsequent corrosion. Repaint after making connections!

• The fastening of the whole variable speed drive housing

must be electrically connected with the mounting plate

over an area which is as large as possible. For this purpose

the removal of paint is necessary. An alternative method

is to connect the variable speed drive housing to the

mounting plate with as short a length of litz wire as pos-

sible.

• Try to avoid interruptions in the screening wherever pos-

sible.

• If the variable speed drive is mounted in a standard cabi-

net, the internal wiring must comply with the EMC

standard. Fig. 23 shows an example of a VSD built into a

cabinet.

NOTE: The Brake and DC-link Terminals are only fitted if

the Brake Chopper Option is built-in.

WARNING: The Brake Resistor must be

connected between terminals DC+ and R.

WARNING: In order to work safely, the mains

earth must be connected to PE and the

motor earth to .

NOTE: It is important that the motor housing has the

same earth potential as the other parts of the machine.

NOTE: The terminals DC-, DC+ and R are options.

Screen connection

of signal cables

PE

Motor cable

shield connection

Loading...

Loading...