Cubemass DCI MODBUS RS485 Wiring

Endress+Hauser 25

4.5 Post-connection check

Perform the following checks after completing electrical installation of the measuring device:

Device condition and specifications Notes

Are cables or the device damaged (visual inspection)? –

Electrical connection Notes

Does the supply voltage match the specifications on the nameplate? 85 to 260 V AC (45 to 65 Hz)

20 to 55 V AC (45 to 65 Hz)

16 to 62 V DC

Do the cables comply with the specifications? → ä 21

Do the cables have adequate strain relief? –

Is the cable type route completely isolated?

Without loops and crossovers?

–

Are the power supply and signal cables correctly connected? È Wiring diagram inside the

cover of the terminal

compartment

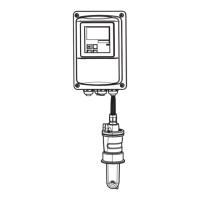

Only remote version:

Is the flow sensor connected to the matching transmitter electronics?

Check serial number on

nameplates of sensor and

connected transmitter.

Only remote version:

Is the connecting cable between sensor and transmitter connected correctly?

→ ä 21

Are all screw terminals firmly tightened? –

Are all cable entries installed, firmly tightened and correctly sealed?

Cables looped as "water traps"?

→ ä 24, "Degree of protection"

section

Are all housing covers installed and firmly tightened? –

Fieldbus electrical connection Notes

Has each fieldbus segment been terminated at both ends with a bus terminator? → ä 56

Has the max. length of the fieldbus cable been observed in accordance with the

specifications?

→ ä 19

Has the max. length of the spurs been observed in accordance with the

specifications?

→ ä 19

Is the fieldbus cable fully shielded and correctly grounded? → ä 20

Loading...

Loading...