Commissioning Cubemass DCI MODBUS RS485

60 Endress+Hauser

6.5 Adjustment

6.5.1 Zero point adjustment

All measuring devices are calibrated with state-of-the-art technology.

The zero point obtained in this way is printed on the nameplate.

Calibration takes place under reference operating conditions → ä 86.

Consequently zero point adjustment is generally not necessary for Cubemass DCI!

Experience shows that the zero point adjustment is advisable only in special cases:

• To achieve highest measuring accuracy also with very small flow rates.

• Under extreme process or operating conditions (e.g. very high process temperatures).

Preconditions for a zero point adjustment

Note the following before you perform a zero point adjustment:

• Adjustment can only be performed on homogeneous fluids.

• Zero point adjustment is performed at zero flow (v = 0 m/s). This can be achieved, for example,

with shutoff valves upstream and/or downstream of the sensor or by using existing valves and

gates.

– Normal operation → valves 1 and 2 open

– Zero point adjustment with pump pressure → Valve 1 open / valve 2 closed

– Zero point adjustment without pump pressure → Valve 1 closed / valve 2 open

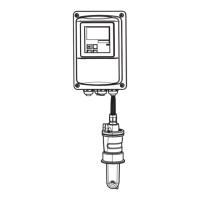

A0003601

Fig. 37: Zero point adjustment and shutoff valves

"

Caution!

• The currently valid zero point value can be viewed using the "ZEROPOINT" function

(È "Description of Device Parameters" manual).

Loading...

Loading...