Cubemass DCI MODBUS RS485 Commissioning

Endress+Hauser 63

6.6 Rupture element

Sensor housings with an integrated rupture element are optionally available.

#

Warning!

• Make sure that the function of the rupture element is not impeded by the installation.

The triggering pressure in the housing is indicated on the information notice.

Take suitable measures to ensure that no damage can occur if the rupture disk is tripped and

personal injury is ruled out.

Triggering pressure in the housing 10 to 15 bar (145 to 217.5 psi)

• Please note that if a rupture disk is used, the housing can no longer assume a secondary

containment function.

• It is not permitted to open the connections or remove the rupture disk.

"

Caution!

• The use of rupture elements cannot be combined with the heating jacket which is available as a

separate element.

• The existing connection nozzles are not designed for a purge or pressure monitoring function.

!

Note!

• The transportation guard on the rupture disk must be removed prior to commissioning.

• Comply with the information on information notices.

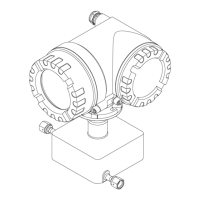

6.7 Purge and pressure monitoring connections

The sensor housing protects the inner electronics and mechanics and is filled with dry nitrogen.

Furthermore, it also has an additional secondary containment function up to a specific measuring

pressure.

#

Warning!

For process pressures above the specified containment pressure, the housing does not provide an

additional secondary containment function. If there is a danger of the measuring tube rupturing due

to process characteristics, e.g. in the event of corrosive process fluids, we recommend the use of

sensors whose housings are equipped with special pressure monitoring connections (ordering

option). With the help of these connections, fluid collected in the housing in the event of a tube

rupture can be drained off. This reduces the risk of mechanical overload of the housing, which could

lead to a housing failure and is thus associated with increased potential danger. The connections can

also be used for gas purging (gas detection).

If measuring gases with high pressures, in particular, we recommend the use of sensors whose

housings are fitted with a rupture element. Users can choose from a rupture disk with defined or

undefined fluid exit. The burst pressure is between 10 and 15 bar (145 to 218 psi) for both options.

Note the following when working with purge and pressure monitoring connections:

• Do not open the purge connections unless the containment can be filled with a dry inert gas

immediately afterwards.

• Use only low overpressure to purge. Maximum pressure 5 bar (72.5 psi).

Loading...

Loading...