iPAK2 User Guide

15

2. Weld Control

iPAK2 controls the weld sequence by using the I/O in conjunction with the welding parameters. The

parameters are stored in programs so that different materials and machine sequences can be used.

There are 256 weld programs.

2.1. Sequence timing

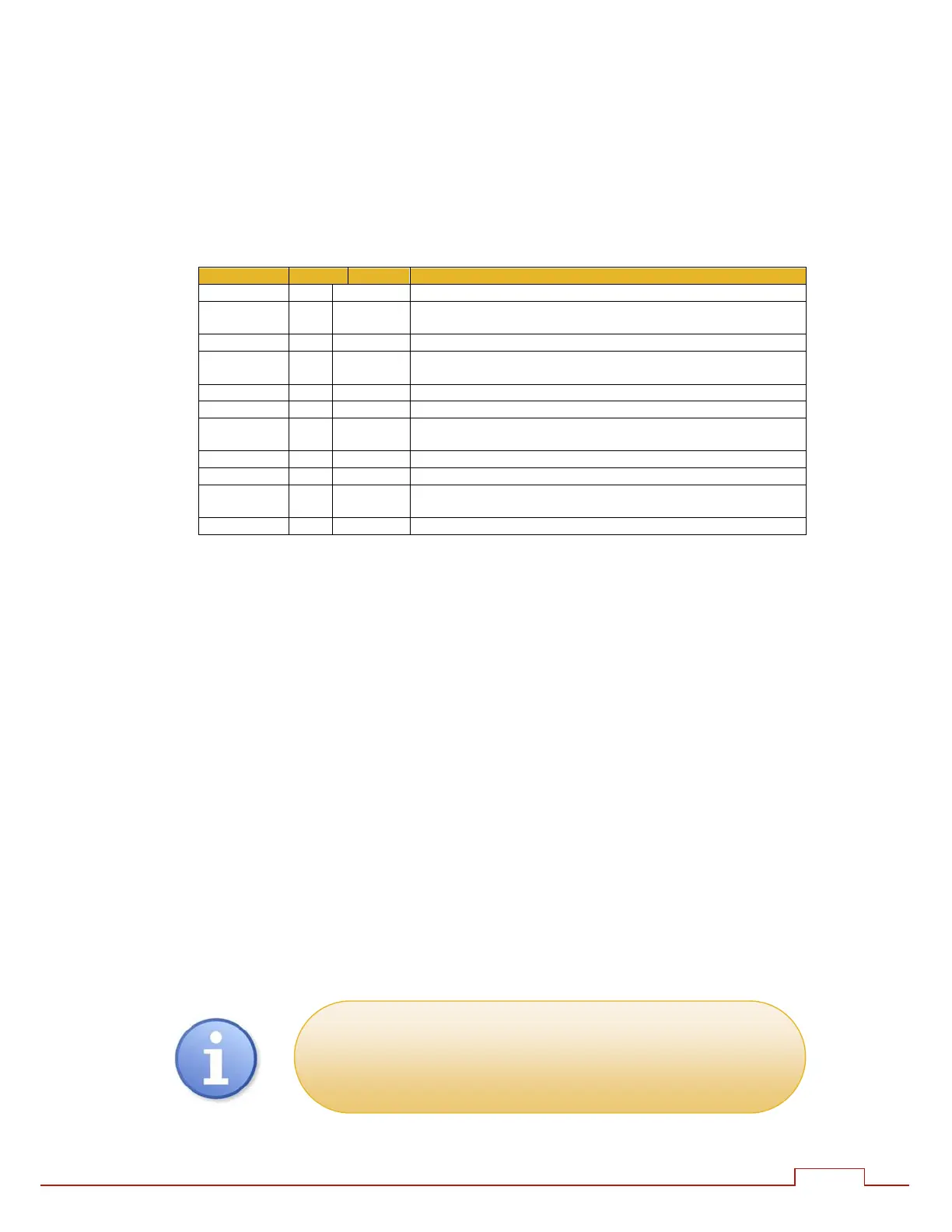

Parameter Units Range Description

Presqueeze ms 0 - 1999 The time for the electrodes to close onto the work piece.

Squeeze ms

0 - 1999

The time between the initial application of the electrode

force and the first application of welding current

Pre-heat

1

ms

0 - 1999

The pre-heat welding current is applied

Cool1

1

ms

0 - 1999

The material is allowed to cool with electrode force

applied

Upslope ms

0 - 1999

Welding current is increased during this time

Main heat ms

0 - 1999

The main welding current is applied

Cool2

2

ms

0 - 1999

The material is allowed to cool with electrode force

applied

Downslope ms

0 - 1999

Welding current is decreased during this time

Post-heat

3

ms

0 - 1999

The post-heat welding current is applied

Hold ms

0 - 1999

Electrode force continues after the welding current has

finished

Off

4

ms

0 - 1999

Electrode force is released until the next sequence begins

1

Pre-heat program option must be enabled to use this feature

2

Pulsations program option must be greater than 1 to use this feature

3

Post-heat program option must be enabled to use this extended feature

4

Repeat mode or Roll-spot program option must be enabled to use this feature

Upslope can be used on hard, irregular shaped, oxidized and

aluminium materials

Downslope can be used to reduce marking and embrittlement

Pre-heat and Post-heat can be used on hard or heat resistant

m

t

l

Loading...

Loading...