iPAK2 User Guide

59

7.5. Parameter programming

This is achieved through the use of the EtherNet/IP explicit messaging service.

The following services are implemented:

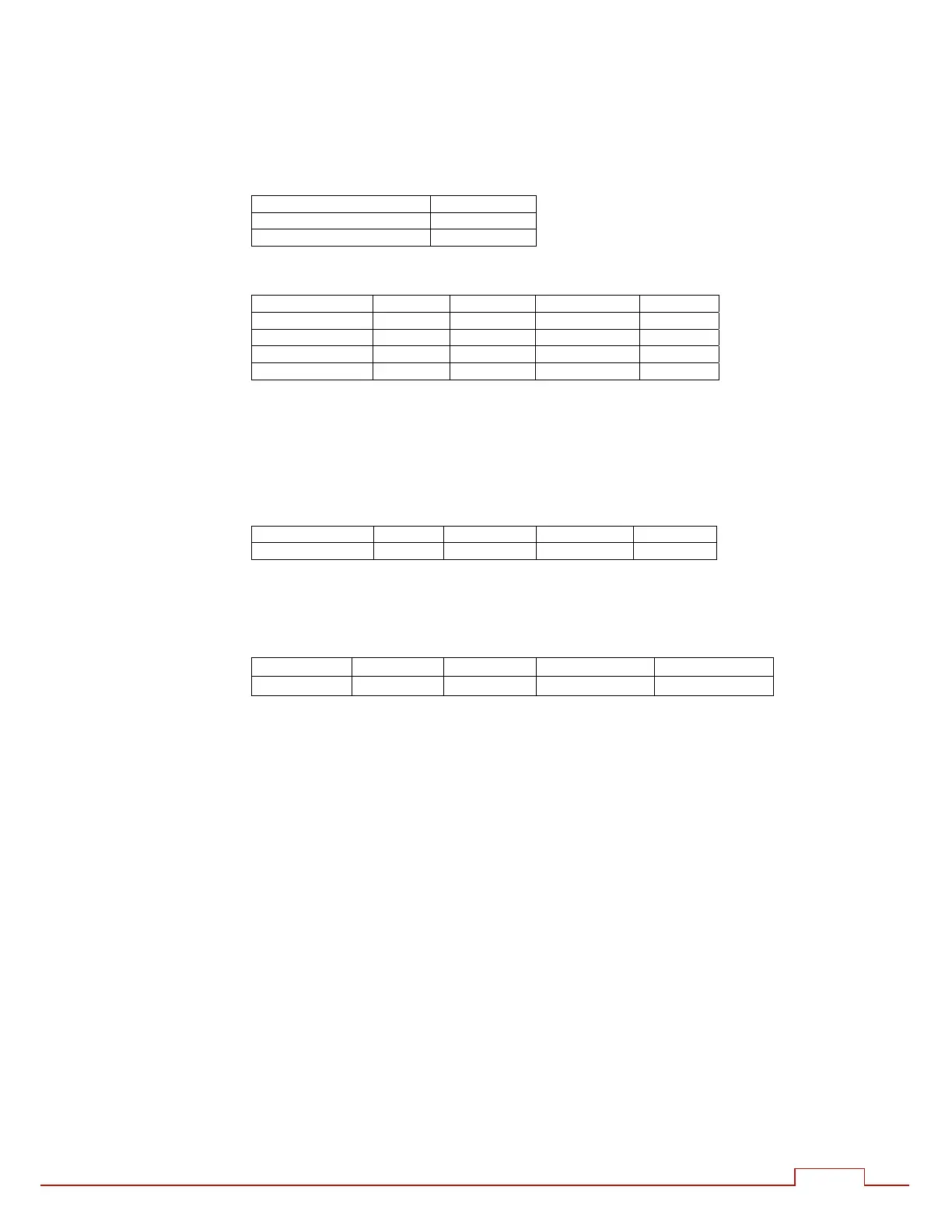

Service Code

Get attribute single 0E (hex)

Set attribute single 10 (hex)

With each of these services, the following objects are available:

Parameters Class ID Instance Attribute ID Size

Weld program 96 (hex) 1 0 to FF (hex) 128 bytes

Electrode 97 (hex) 1 0 to 7 128 bytes

Calibration 98 (hex) 1 0 to 7 128 bytes

Configuration 99 (hex) 1 0 128 bytes

Data should be interpreted as 16-bit words, in little-endian format (lsb sent first). The definition of

these words can be found in the Modbus section of this manual.

For example, to modify a weld parameter in program p (0 to 255):

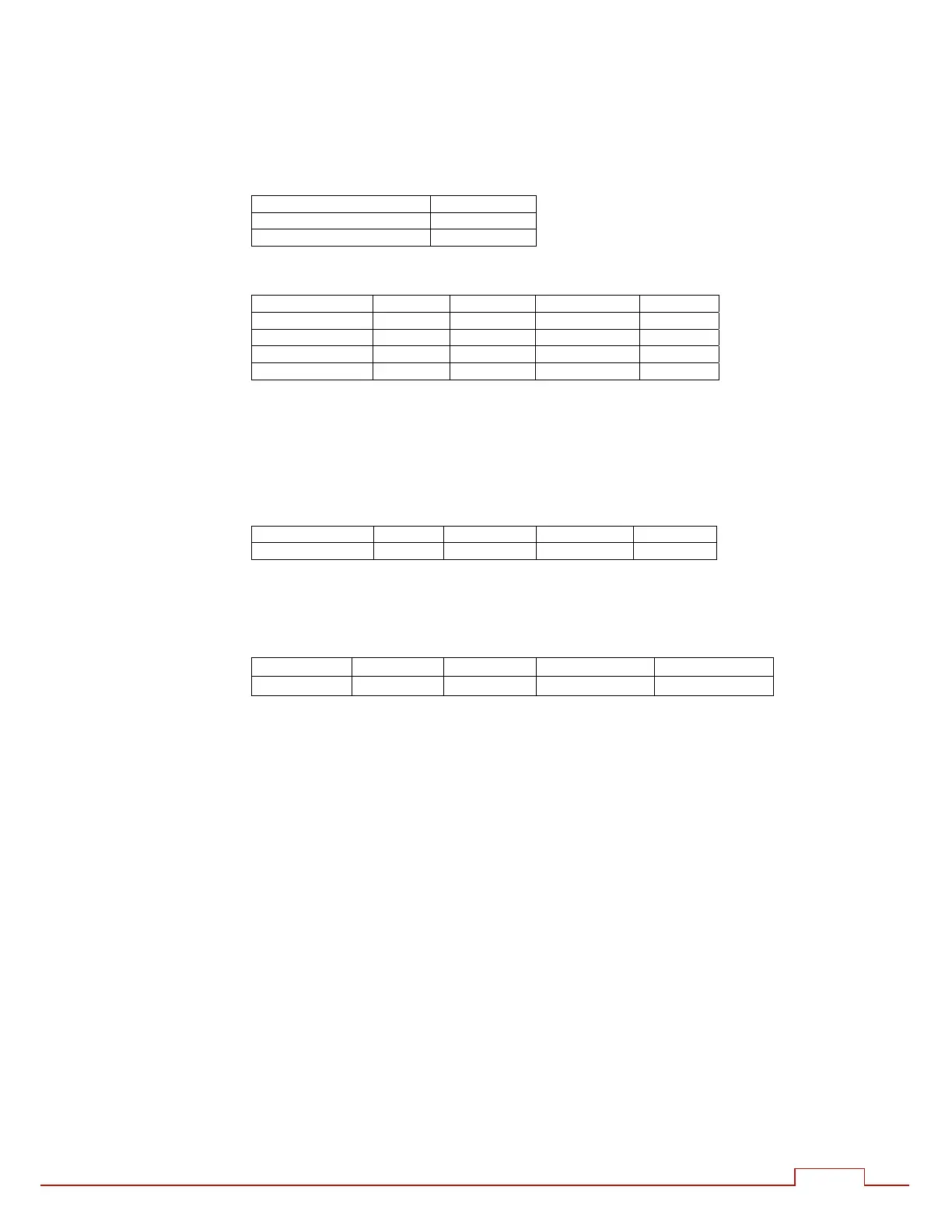

1. Get the weld program from the control by sending the explicit message:

Service Class ID Instance Attribute ID Data

0E (hex) 96 (hex) 1 p none

This returns the 64-word (128 bytes) program structure.

2. Modify the parameter(s) as required.

3. Send the modified program back to the control with the explicit message:

Service Class ID Instance Attribute ID Data

10 (hex) 96 (hex) 1 p 128 bytes

7.6. Interfacing with a PLC

A separate document is available which details an example on how to interface with a

PLC.

Loading...

Loading...