iPAK2 User Guide

62

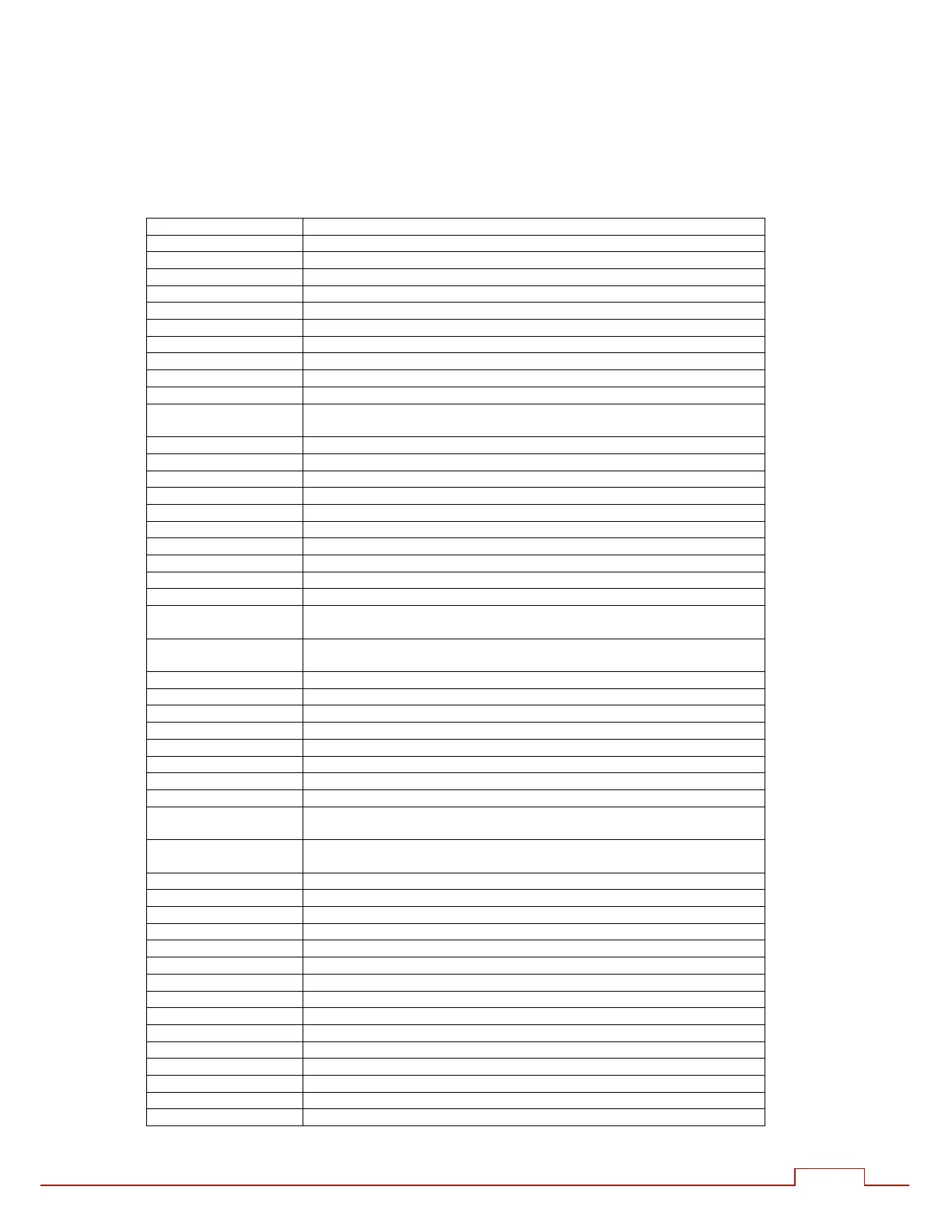

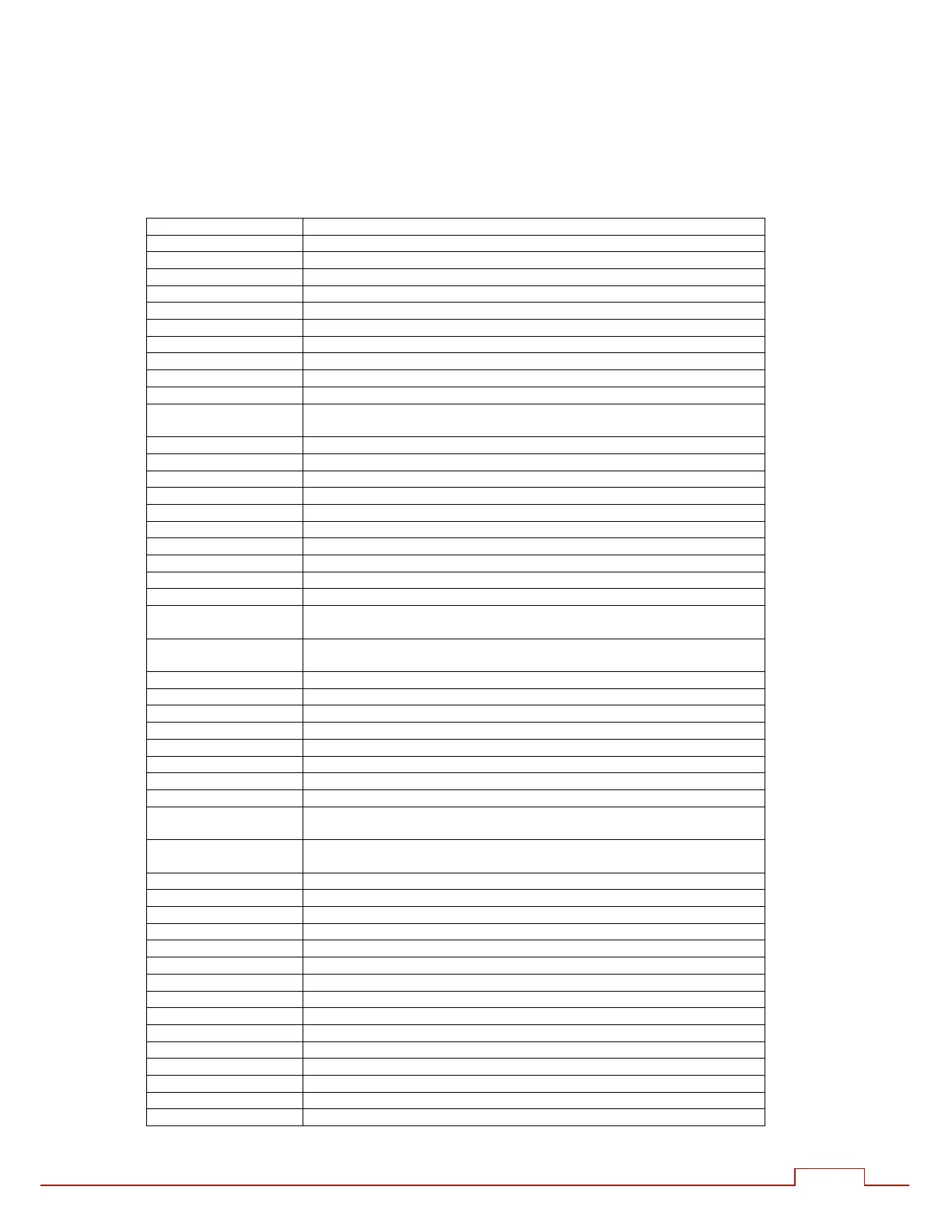

10. Status messages

NetFlash and WSP3 show these status messages. They are also available on the bus outputs – See

Modbus and EtherNet/IP sections.

Stop Check the Stop input

Reserved

Retract not ready Operate the Retract input

Inverter hot Check inverter cooling

Transformer hot Check weld transformer cooling

Pilot fault Safety relay fault. Do not use the iPAK2 and return it for service.

Restart required Restart the iPAK2

Headlocked The welding head is locked because of a fault condition

Toroid short circuit Connection to Toroid (secondary feedback coil) is short-circuit

Toroid open circuit Connection to Toroid (secondary feedback coil) is open-circuit

Test mode For service use only

Start on The Start input is on following a weld sequence or stop/power-up

condition

Weld off Check the Weld On input

Program inhibited The selected weld program is inhibited

Output fault One or more outputs have failed

Too many links Too many weld programs are linked together

Bad link A link has been made to a weld program that cannot be used

Max. current Check secondary circuit. Reduce heat/current.

Toroid overrange Reduce current or use an external signal attenuator

CT overrange Check calibration parameters

Max. pulse width Check secondary circuit. Reduce heat/current.

Calibration error Check parameters in calibration program

Low force Check the analog input and output circuits and/or adjust force

parameters

High force Check the analog input and output circuits and/or adjust force

parameters

Low pre-current Check CT/toroid feedback and/or adjust Pre-heat parameters

High pre-current Check CT/toroid feedback and/or adjust Pre-heat parameters

Low main current Check CT/toroid feedback and/or adjust Main heat parameters

High main current Check CT/toroid feedback and/or adjust Main heat parameters

Low post-current Check CT/toroid feedback and/or adjust Post-heat parameters

High post-current Check CT/toroid feedback and/or adjust Post-heat parameters

No 2

nd

stage Check the 2

nd

Stage input

No force Check analog input circuit

Low conduction

(Shunt)

There may be a shunt condition on the weld transformer secondary

circuit

High conduction

(wear)

The weld transformer secondary circuit may have degraded.

End of count 0 Reset counter 0

End of count 1 Reset counter 1

End of count 2 Reset counter 2

End of count 3 Reset counter 3

End of count 4 Reset counter 4

End of count 5 Reset counter 5

End of count 6 Reset counter 6

End of count 7 Reset counter 8

End of electrode 0 Reset stepper 0

End of electrode 1 Reset stepper 1

End of electrode 2 Reset stepper 2

End of electrode 3 Reset stepper 3

End of electrode 4 Reset stepper 4

End of electrode 5 Reset stepper 5

End of electrode 6 Reset stepper 6

Loading...

Loading...