iPAK2 User Guide

63

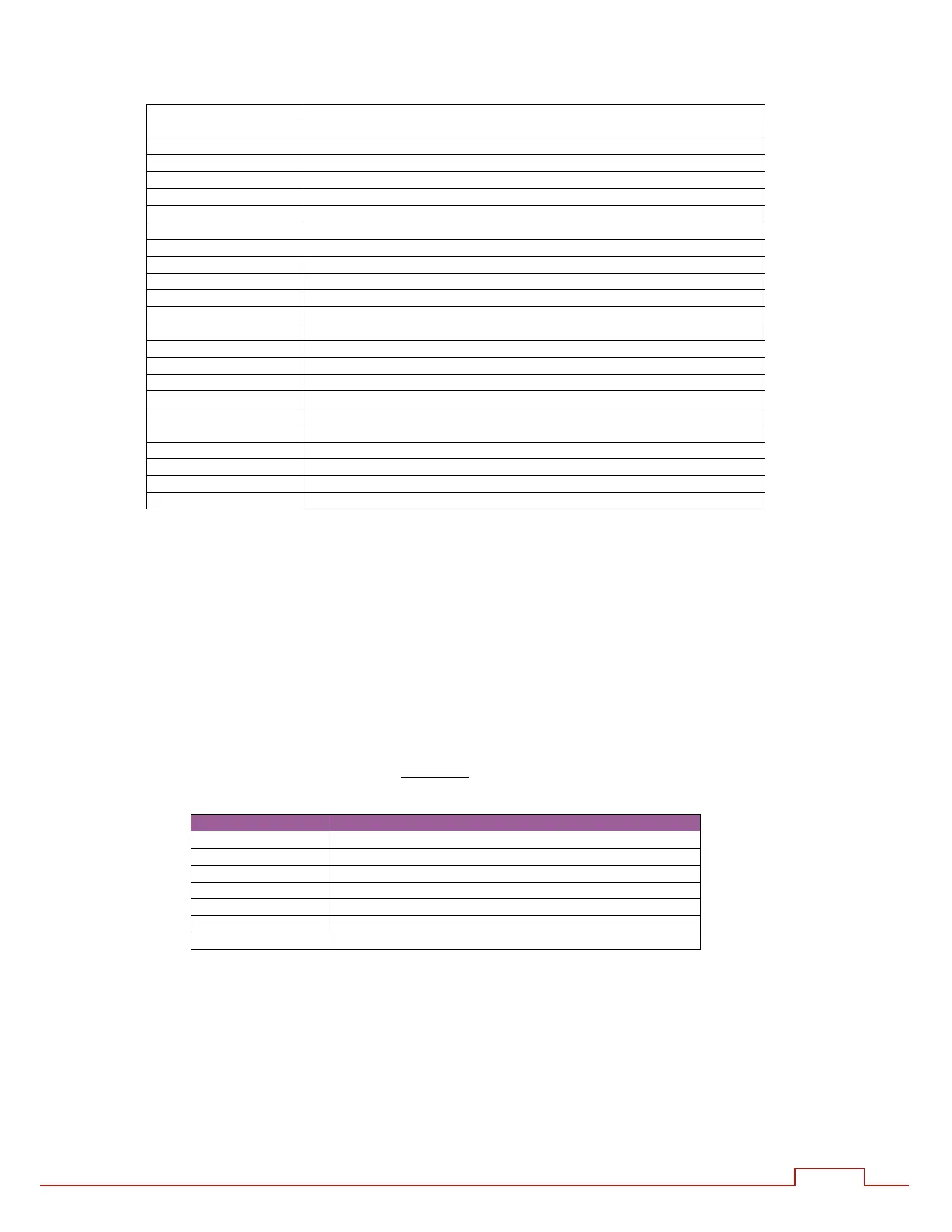

End of electrode 7 Reset stepper 7

Tip dress 0 Dress the electrodes and then reset counter 0

Tip dress 1 Dress the electrodes and then reset counter 1

Tip dress 2 Dress the electrodes and then reset counter 2

Tip dress 3 Dress the electrodes and then reset counter 3

Tip dress 4 Dress the electrodes and then reset counter 4

Tip dress 5 Dress the electrodes and then reset counter 5

Tip dress 6 Dress the electrodes and then reset counter 6

Tip dress 7 Dress the electrodes and then reset counter 7

Prewarn 0 Stepper 0 has completed its 9th step

Prewarn 1 Stepper 1 has completed its 9th step

Prewarn 2 Stepper 2 has completed its 9th step

Prewarn 3 Stepper 3 has completed its 9th step

Prewarn 4 Stepper 4 has completed its 9th step

Prewarn 5 Stepper 5 has completed its 9th step

Prewarn 6 Stepper 6 has completed its 9th step

Prewarn 7 Stepper 7 has completed its 9th step

Inverter DC BUS error Check inverter

Inverter short circuit Check inverter

Inverter fan failure Check inverter

Inverter not ready Wait for inverter to charge

Inverter config error LMI units only

LMI error Check indication on LMI module

Duty cycle limit Reduce duty and/or current

11. History log

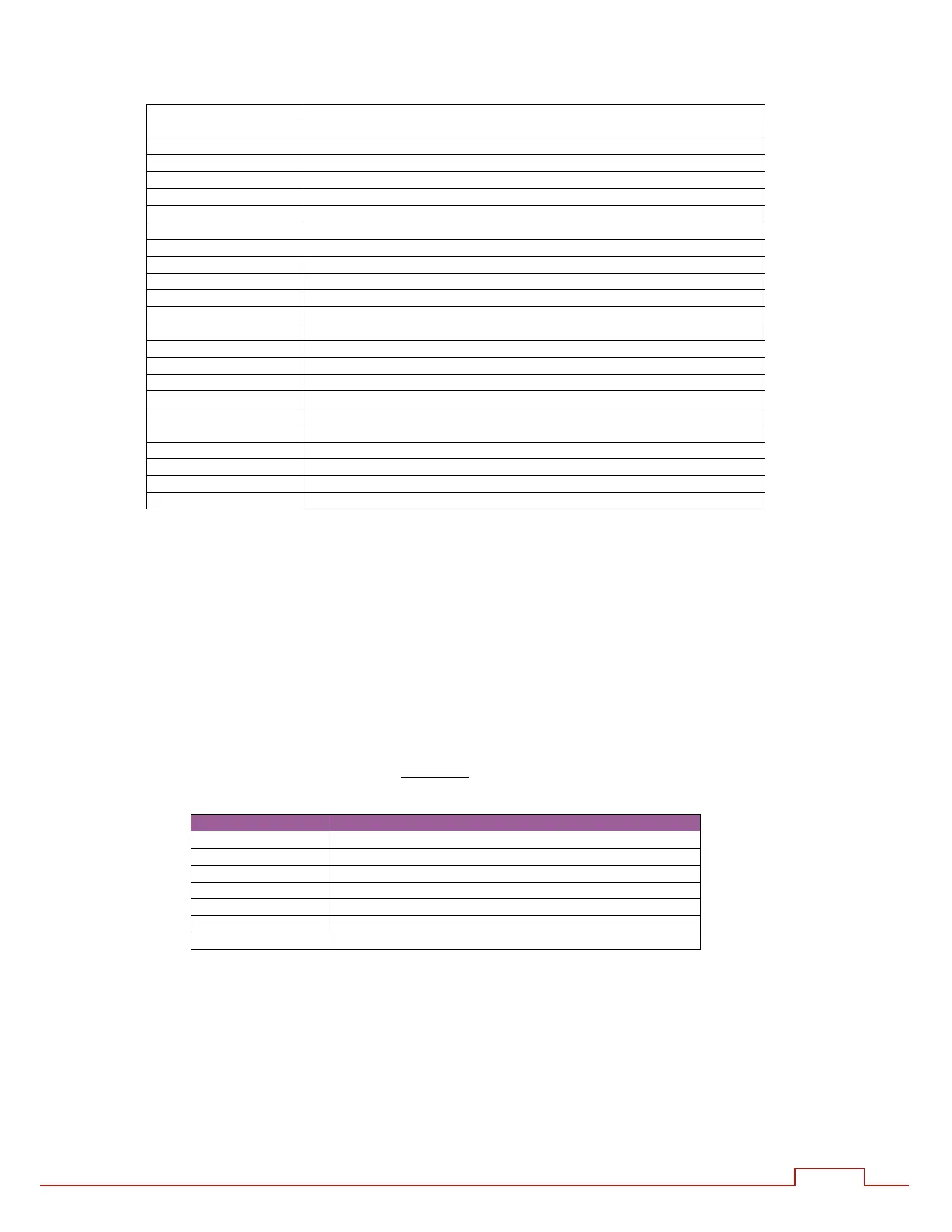

iPAK2 stores the results of the last 6000 spot welds in a history log. Each record contains the following

information:

Parameter Description

Time and date The time and date when the weld was made

Program The weld program used

Pre-current The current measured during the Pre-heat interval

Main current The current measured during the Main heat interval

Post-current The current measured during the Post-heat interval

Force The force measured during the weld

Pulse width The conduction measured during the weld

The log can be viewed or reset as required via WSP3 or NetFlash. When using NetFlash, this log can be

downloaded to the screen and stored in a file. Subsequent welds are also displayed and stored.

Loading...

Loading...