iPAK2 User Guide

27

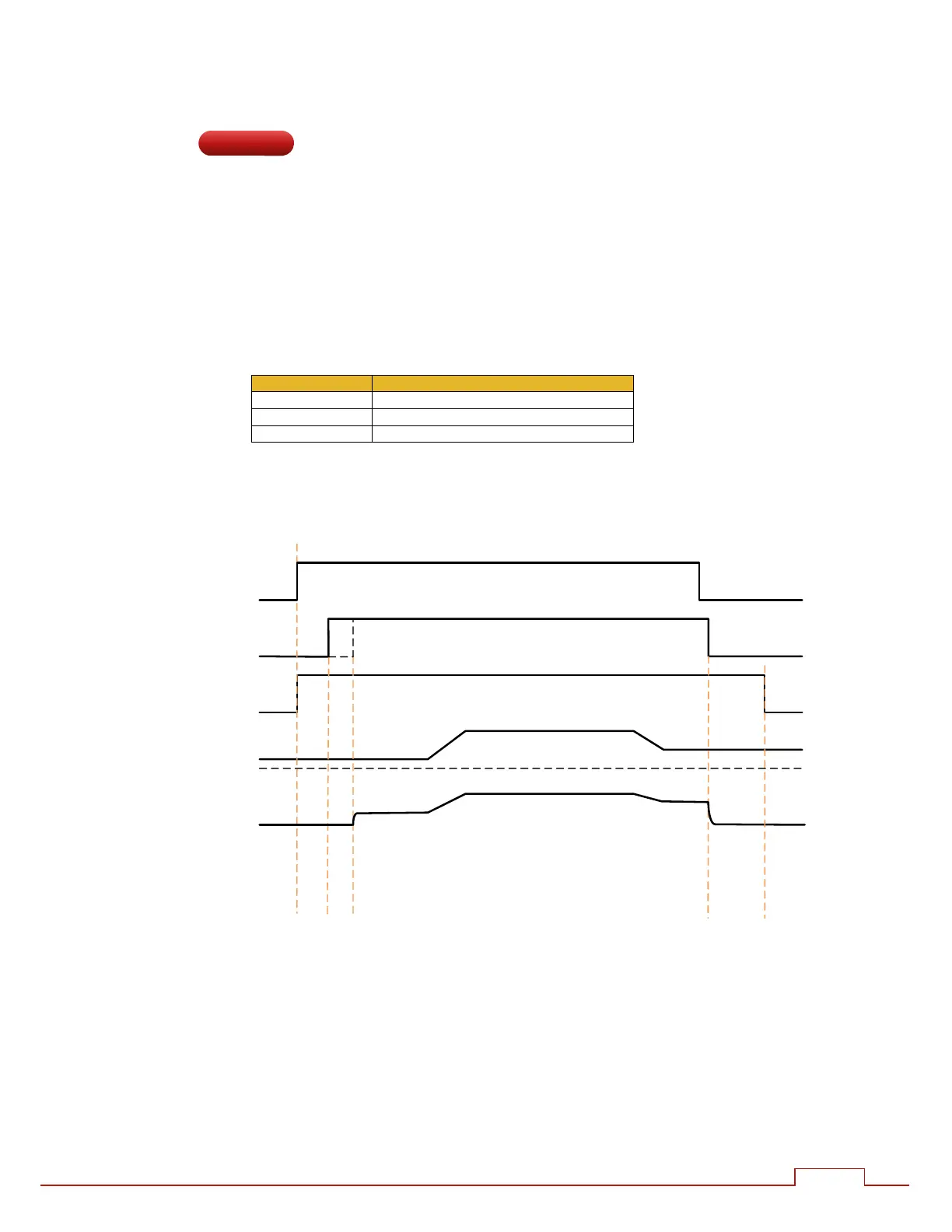

2.9. Analog control

If the ‘Analog control’ configuration parameter is set to ‘ON’, then the output current can be

controlled by applying a 0 to 10 Volt signal to P4 pins 1(+) and 2(-). The program will track the

analog input, allowing the user to create custom current profiles.

Note:

Pre-heat and post-heat are not available

Force feedback is not available

The input signal will control a different parameter depending on the mode set in the selected

weld program:

Main mode 0 to 10 V input signal controls

PW 0 to 100% pulse-width

CCu 0 to 100% heat (configured current)

CCC 0 to 100% calibrated current.

e.g. Seam weld, Cool 2 = 0.

MOTORO/P

WAVO/P

AnalogI/P

Current

Presqueeze

Squeeze

Hold

STARTI/P

Mainheat

Extended

Loading...

Loading...