iPAK2 User Guide

70

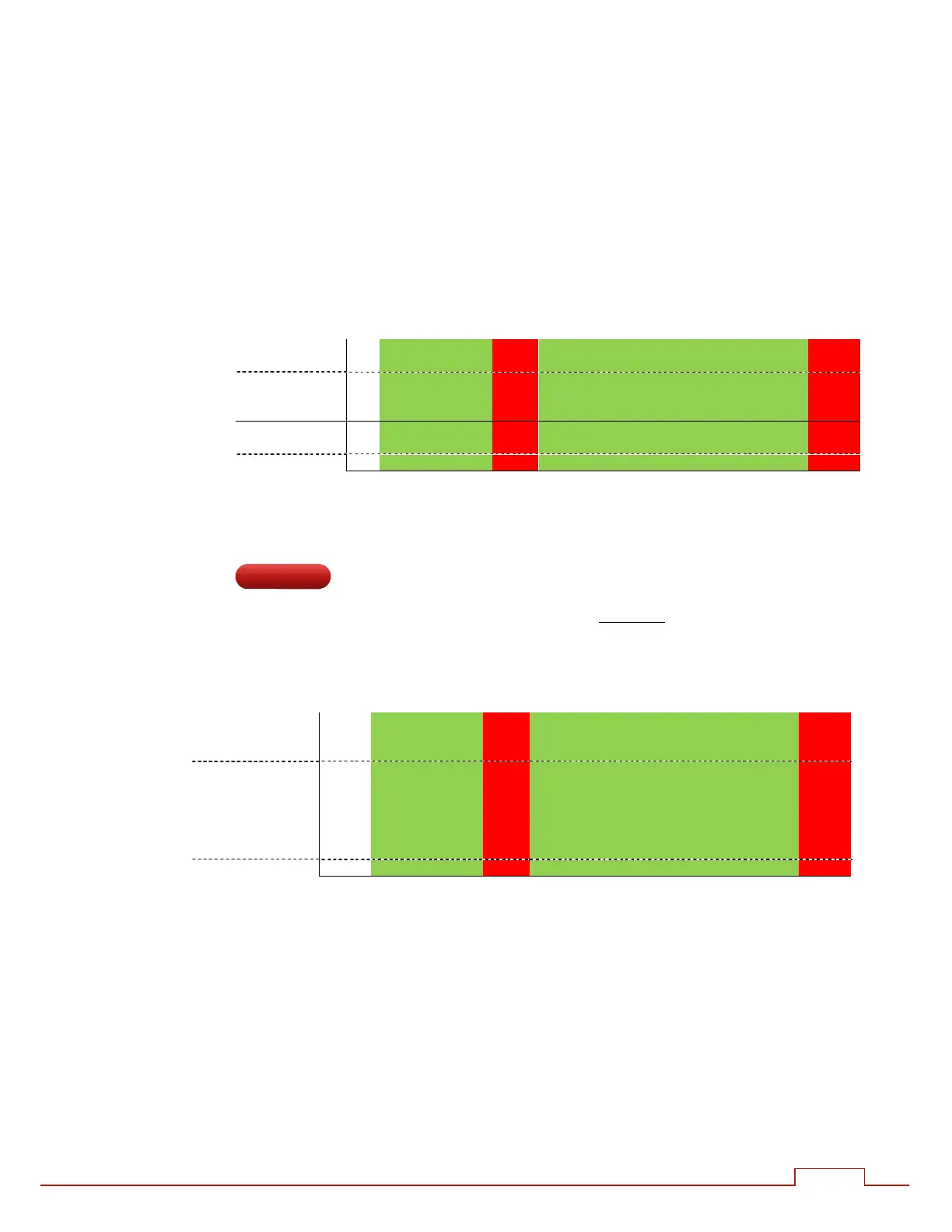

13.2. Testing the weld current

13.2.1. Current monitor

The current for each weld can be tested against upper and lower limits.

1. In the weld program, enable the Test current option for each weld to be

tested.

2. Set the Low limit and High limits appropriately. The limits correspond to a

percentage of the required current.

If the weld current falls outside the limits, iPAK2 will signal a fault.

Current

Pass Fault Pass Fault

High limit

Target

Low limit

Spots

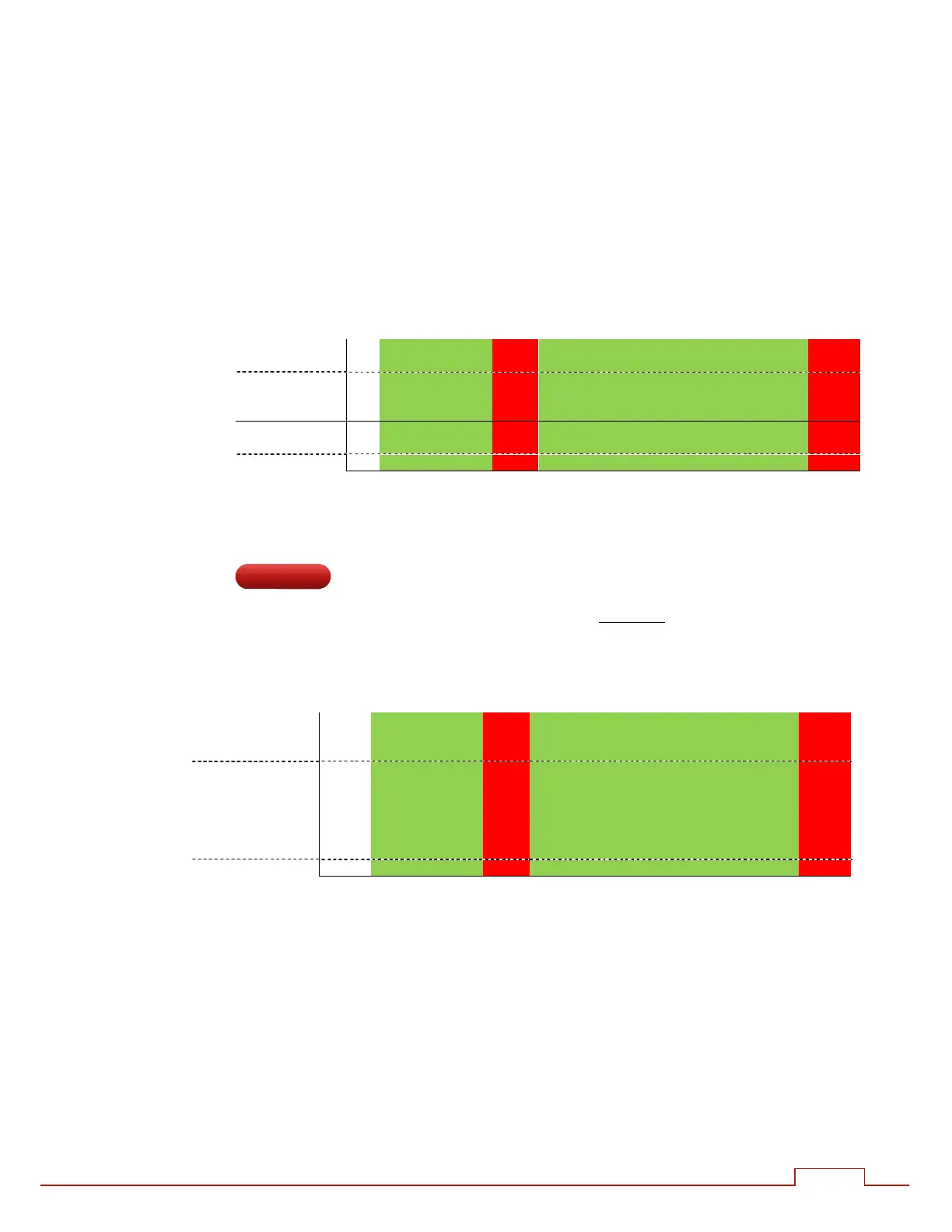

13.2.2. Conduction monitor (C-Monitor)

The control measures the percentage conduction of the Main-heat interval. The user may

set low (shunt) and high(wear) limits, thus setting an acceptance window. These limits are

absolute values (they are not percentages of the measurement). If the measured

conduction is found to be outside of these limits, the iPAK2 will signal a fault.

%Conduction

Pass Fault Pass Fault

Wear

limit

Shunt

limit

Spots

When using constant current, the conduction will vary as the control applies

compensation. Low conduction can be indicative of a shunt condition on the welding

transformer secondary circuit. High conduction can be indicative of secondary circuit

wear. Be sure to use CCR mode for the main heat

Extended

Loading...

Loading...